Manufacturing method for die assembly fixing tool used for die drilling

A technology for fixing tooling and molds, which is applied in the direction of drilling molds for workpieces, etc., can solve the problems of poor fixing effect of fixing devices, poor practicability, manual fixing, etc., and achieve manpower saving, simple structure, and convenient rotation and replacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

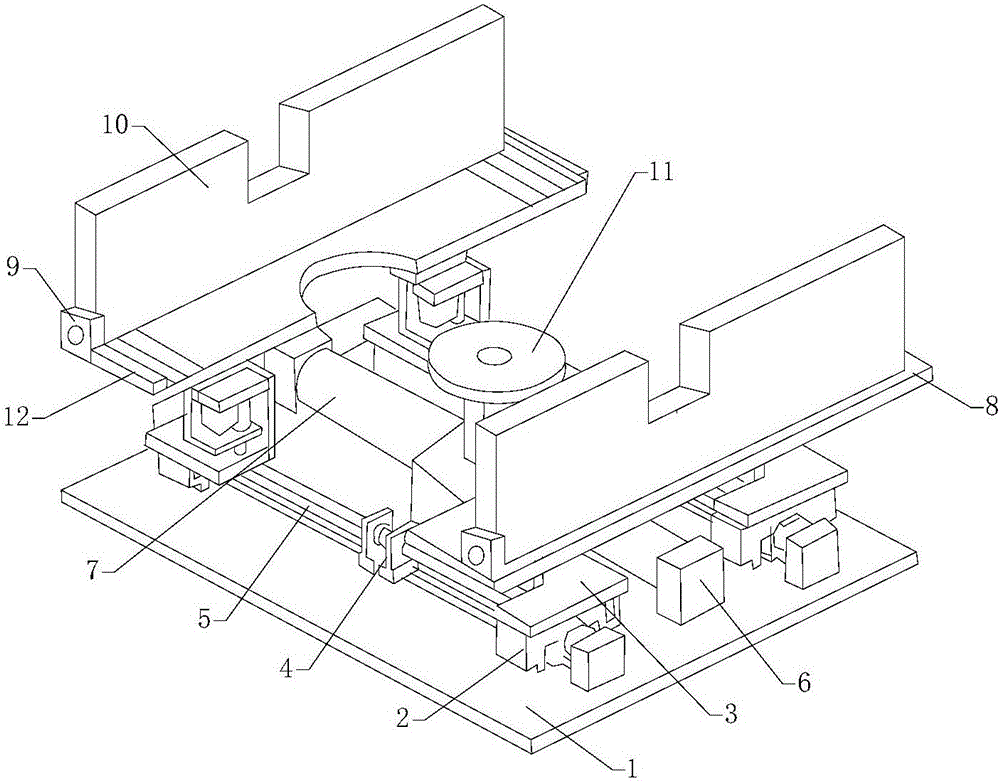

[0022] Such as figure 1 As shown, the preparation method of the mold clamping fixture for mold drilling includes a base plate 1, a guide rod 4, a moving frame 2 and a mold base plate, and the mold base described is divided into a preparatory plate 10 and a main board 8;

[0023] The base plate 1 is provided with a support rod 7, the support rod 7 is provided with a supporting plate 11, the base plate 1 is provided with a guide rod 4, and the mobile frame 2 passes through the guide rod 4, The main board 8 is installed on the mobile frame 2 , and the preparatory board 10 is installed on the main board 8 .

[0024] The bottom plate 1 is provided with a guide groove 5, the bottom of the mobile frame 2 is installed on the guide groove 5, and the two ends of the guide groove 5 are provided with limit blocks 6, and the guide rod 4 and the limiter Block 6 is connected.

[0025] The two ends of the main board 8 are provided with a plurality of chutes, the two ends of the main board 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com