Glass pressing equipment

A technology for laminating equipment and glass, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems such as the change of the lamination position of the door frame and the glass, the low accuracy of manually fixing the door frame, and the influence on the quality of the glass panel of the refrigerator. To achieve the effect of providing production quality and production efficiency, good pressing quality and high pressing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

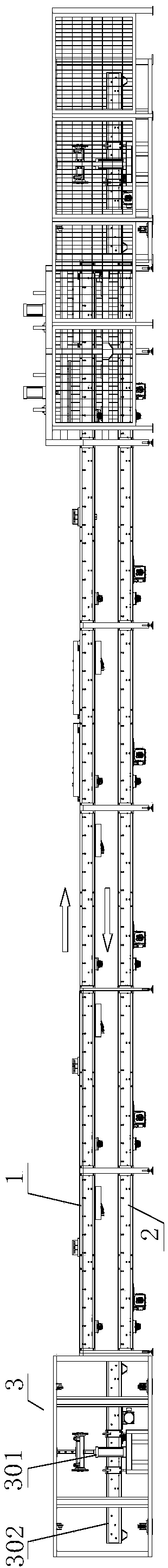

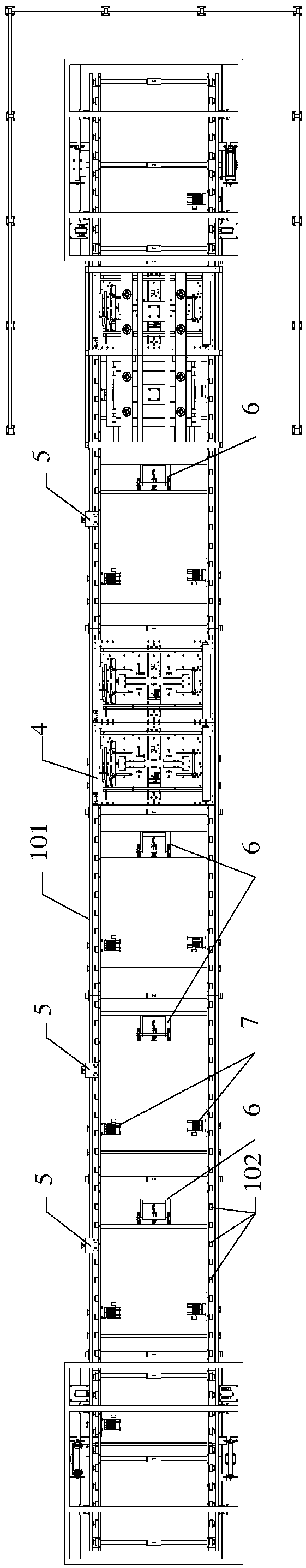

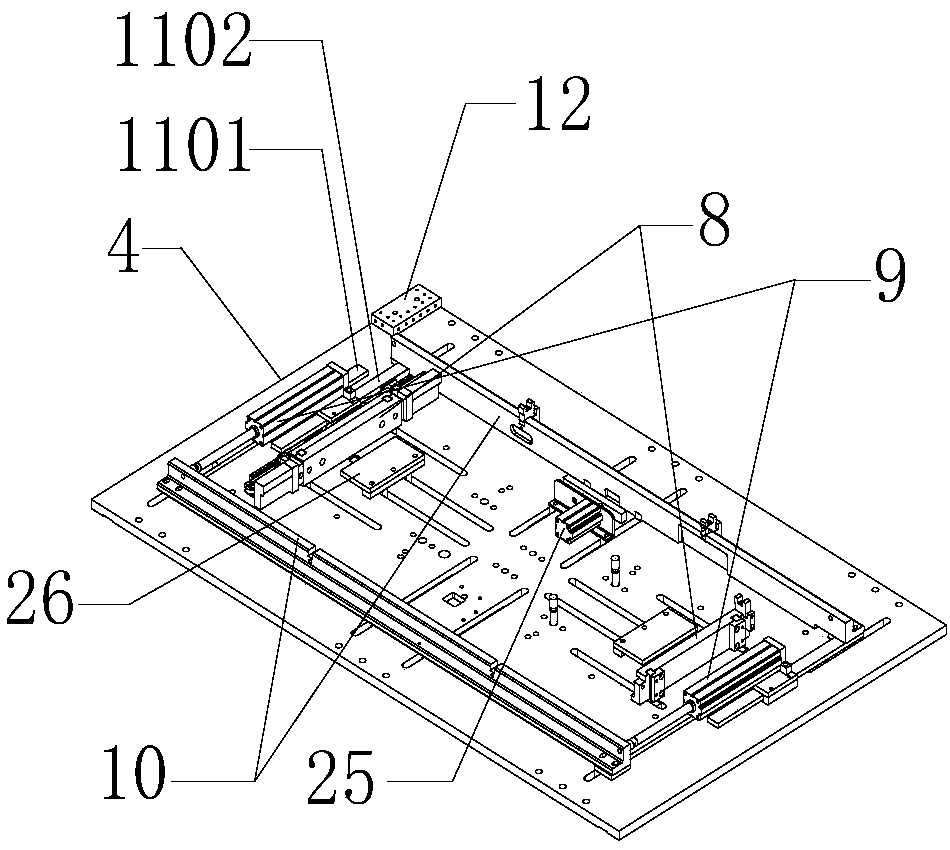

[0029] Such as figure 1 As shown, the glass pressing equipment includes an upper transmission line 1 and a lower transmission line 2 , and the upper transmission line 1 is located directly above the lower transmission line 2 . Both ends of the upper transmission line 1 and the lower transmission line 2 are equipped with a tooling circulation lifting system 3, the tooling circulation lifting system 3 includes a lifting cylinder 301, a lifting tray 302, a proximity switch and a photoelectric sensor, and the lifting tray 302 is arranged on the piston of the lifting cylinder 301. On the rod, the lifting cylinder 301 moves to drive the lifting pallet 302 to rise and fall. When the lifting tray 302 rises to be level with the upper transmission line 1, the lifting tray 302 at one end transports the unprocessed tooling board to the upper transmission line 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com