A double-layer structure vacuum suction table

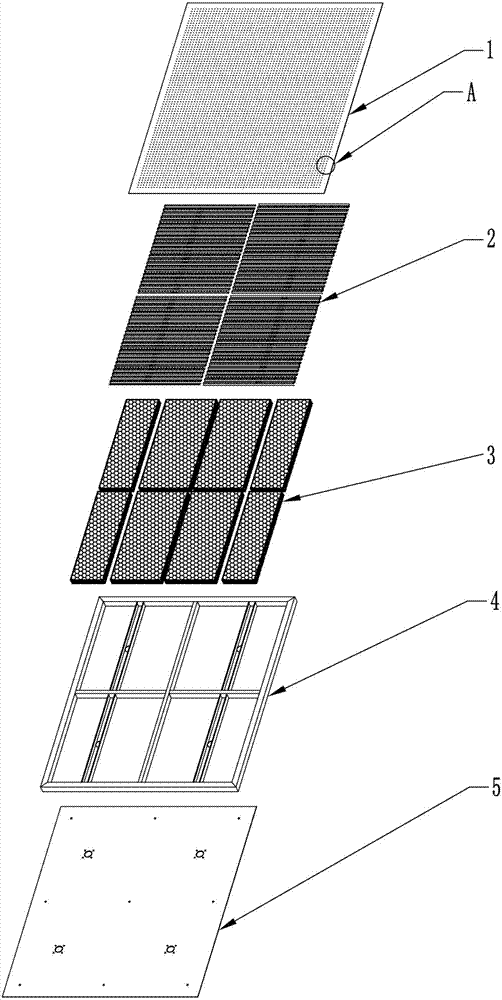

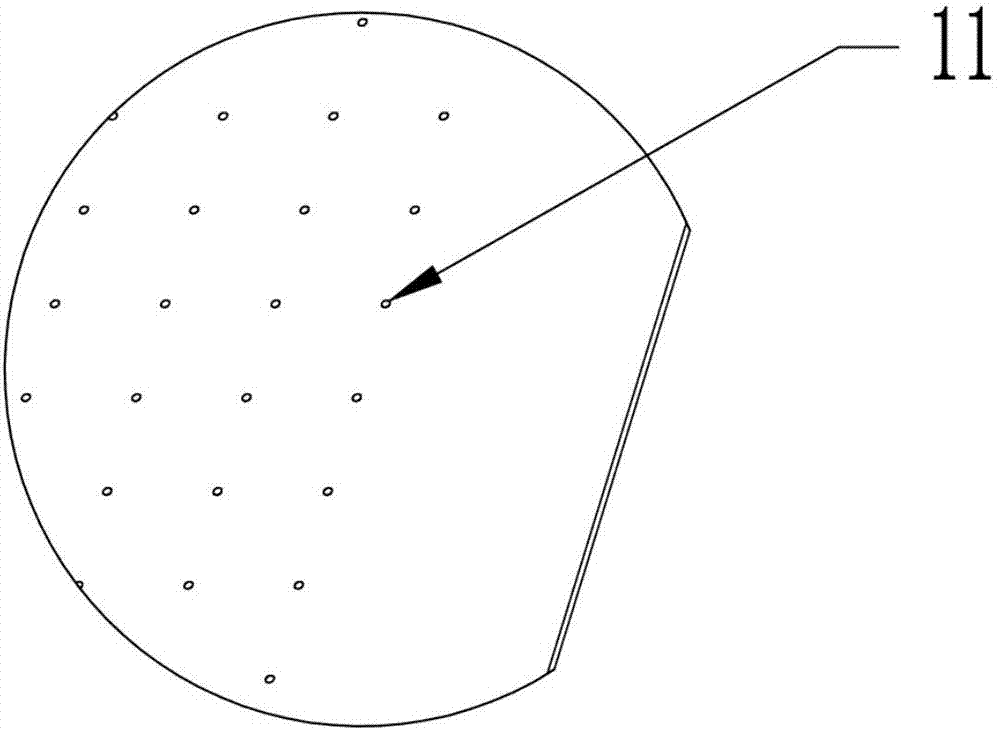

A double-layer structure, vacuum suction technology, applied in the direction of workpiece clamping devices, manufacturing tools, etc., can solve the problems of large airflow energy loss, limited precision, low strength of vacuum suction table, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

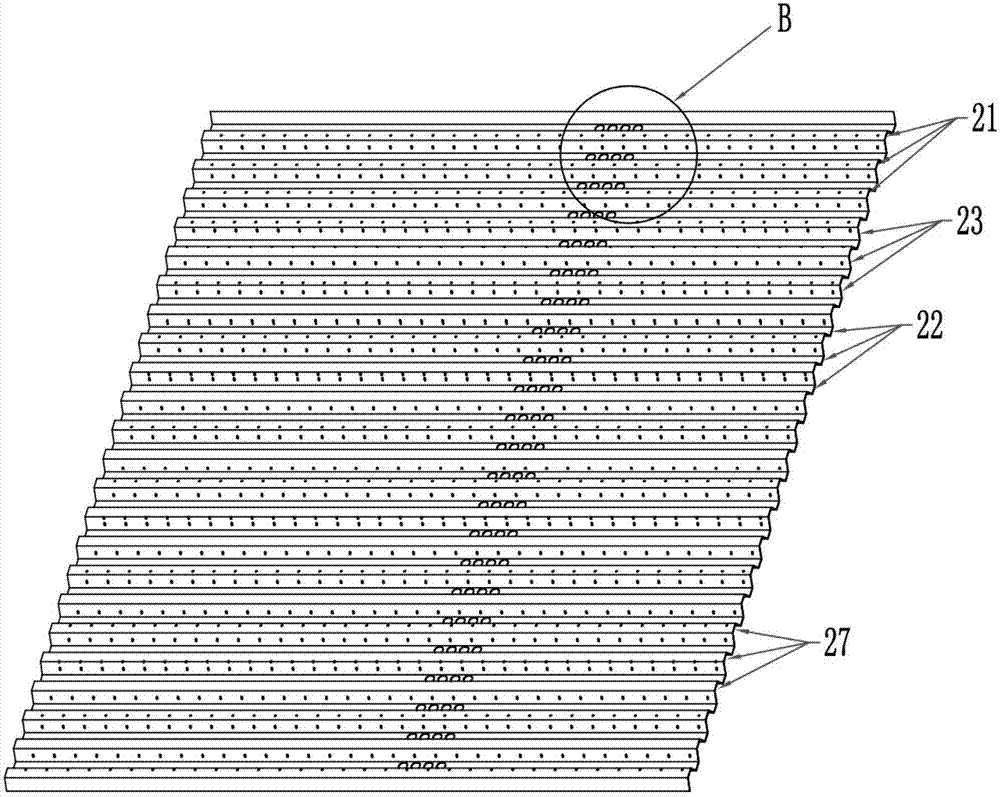

[0034] Such as Figure 5 As shown, the upper and lower end surfaces (21, 22) of the corrugated core 2 are horizontal planes. Specifically, the corrugated core 2 is composed of a plurality of trapezoidal structures 6 connected at intervals. The waist planes 61 on both sides of the surface 60 are open at the bottom. A plurality of upper step surfaces 60 spaced apart form the upper end surface 21, and the connecting surface 62 between the trapezoidal structures 6 forms the lower end surface 22. The waist plane 61 of the trapezoidal structures 6 forms the upper end surface 21. The connecting surface 23 is supported, so that the upper step surface 60 and the waist planes 61 on both sides constitute the above-mentioned ventilation area 27 .

Embodiment 2

[0036] This embodiment is basically similar in structure and principle to the above-mentioned embodiment 1, the difference is that the upper and lower end surfaces (21, 22) of the corrugated core 2 are arc-shaped end surfaces. For example: the corrugated core 2 is in a wave shape, which includes a crest section and a trough section, and a transition section connecting the crest section and the trough section, each crest section forms the upper end surface, each trough section forms the lower end surface, and each transition section forms The supporting connection surface.

[0037] In addition, in the above-mentioned Embodiment 1 and Embodiment 2, the frame 4 is surrounded by the outer profile 42, and the inside of the frame 4 is fixedly connected with the air duct profile 43, and the air duct profile 43 divides the inner area of the frame into one or more than one The installation area 41 of the air duct profile 43 includes a bottom plane and side planes extending upwards an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com