Module assembling device

A technology for assembling equipment and modules, used in optics, lamination auxiliary operations, instruments, etc., to achieve the effect of improving work efficiency, reducing operators, and reducing human resource costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

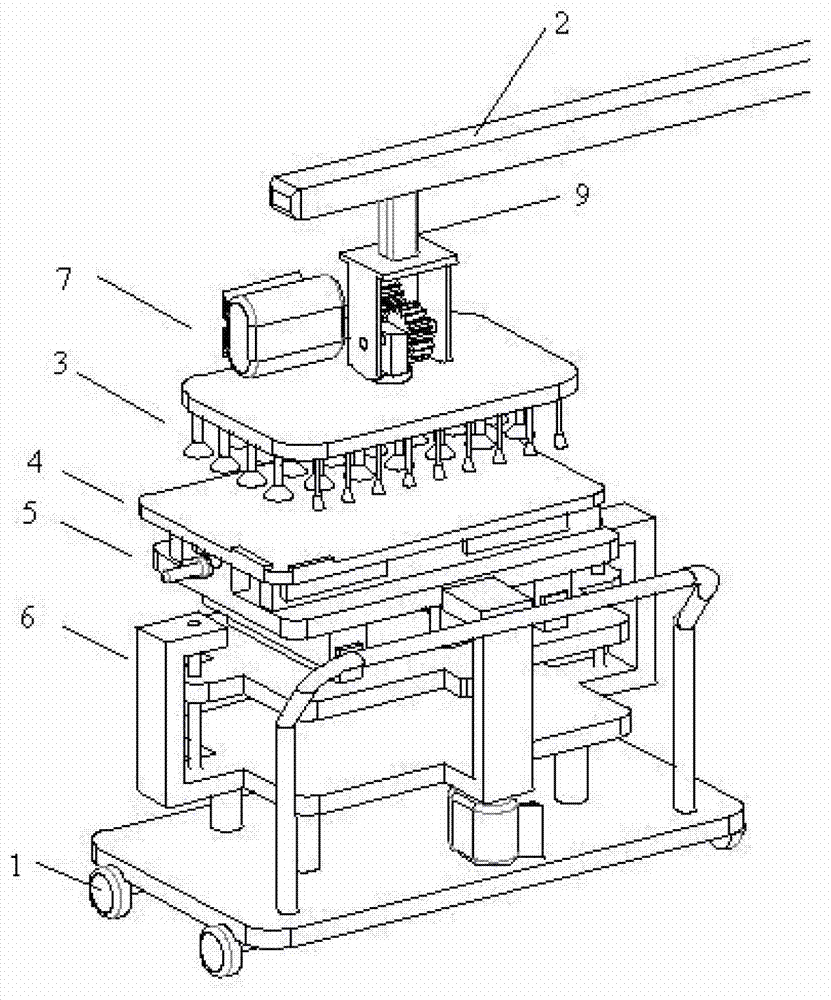

[0029] This embodiment provides a module assembly device, including: a carrying platform for carrying a backlight module; a pick-up unit for picking up and releasing a liquid crystal module; and a carrying platform moving mechanism for moving the carrying platform.

[0030] When the module assembly equipment of this embodiment is used for module assembly, the backlight module is placed on the carrying platform first, and the liquid crystal module is picked up by the pick-up unit, and the carrying platform is moved by the moving mechanism of the carrying platform to make the backlight module on it The group and the liquid crystal module picked up by the pick-up unit are aligned, and after alignment, the liquid crystal module is released by the pick-up mechanism, and the liquid crystal module and the backlight module are assembled.

[0031] In this embodiment, the movement of the backlight module realizes mechanized operation, which avoids the inconvenience caused by manually mov...

Embodiment 2

[0033] This embodiment provides a module assembly device, including: a carrying platform for carrying the backlight module; a pick-up unit for picking up and releasing the liquid crystal module; and a pick-up unit moving mechanism for moving the pick-up unit.

[0034]When the module assembly equipment of this embodiment is used for module assembly, the backlight module is first placed on the carrier platform, the liquid crystal module is picked up by the pick-up unit, and the liquid crystal module is moved by the pick-up unit moving mechanism so that it is in contact with the backlight module. After alignment and alignment, the liquid crystal module is released by the pick-up mechanism, and the liquid crystal module and the backlight module are assembled.

[0035] In this embodiment, the movement of the liquid crystal module realizes mechanized operation, which avoids damage to the liquid crystal module caused by manual movement of the liquid crystal module; the picking of the ...

Embodiment 3

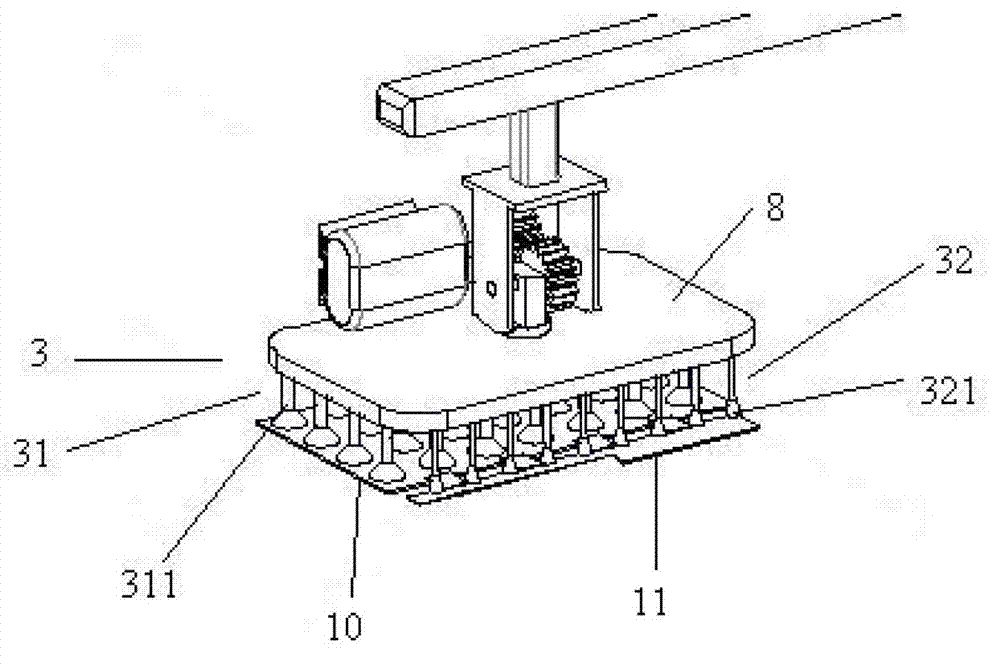

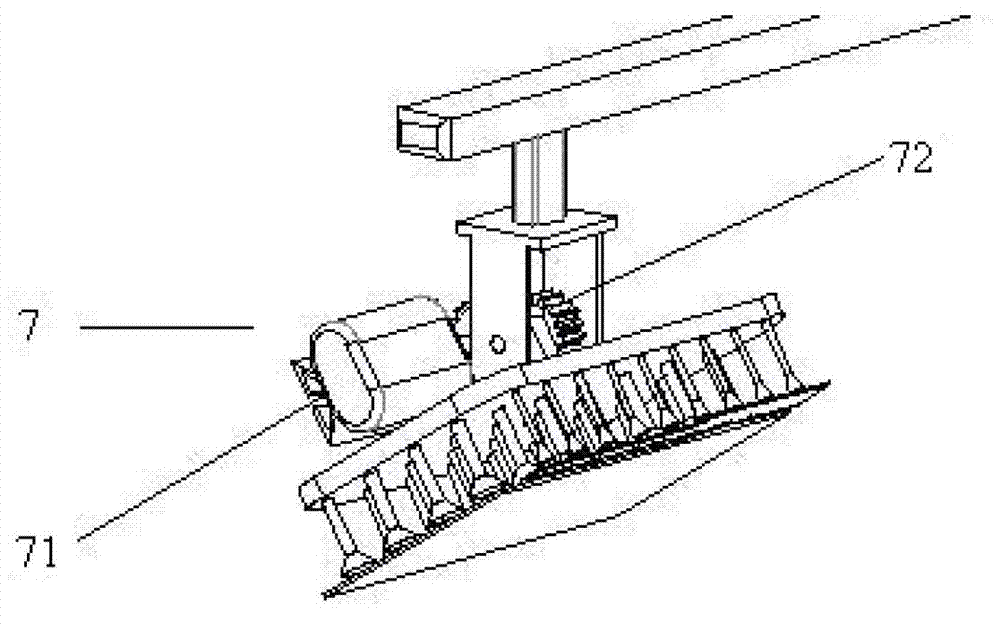

[0037] Such as Figure 1 to Figure 5 As shown, the present embodiment provides a module assembly device, including: a carrying platform 41 for carrying the backlight module; a pick-up unit for picking up and releasing the liquid crystal module 12; a carrying platform for moving the carrying platform 41 Moving mechanism; Picking unit moving mechanism for moving the picking unit.

[0038] Both the moving mechanism of the carrier table and the moving mechanism of the pick-up unit can realize the alignment of the backlight module and the liquid crystal module 12 mechanized, thereby realizing the mechanized movement of the backlight module and the liquid crystal module 12, and avoiding the possibility of manual movement of the liquid crystal module 12. Damage to the liquid crystal module 12 improves the yield, reduces operators, improves work efficiency, and reduces human resource costs.

[0039] Preferably, as figure 2 As shown, the pick-up unit includes a suction mechanism 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com