Tail end boom posture multi-mode automatic control device and method for tunnel multi-boom and multi-joint operation equipment

A technology of operating equipment and multi-boom, which is applied in the direction of program-controlled manipulators, manufacturing tools, manipulators, etc., can solve problems such as complex movement control of the boom, meet the requirements of intelligent control, realize intelligent automatic control, and reduce the difficulty of control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

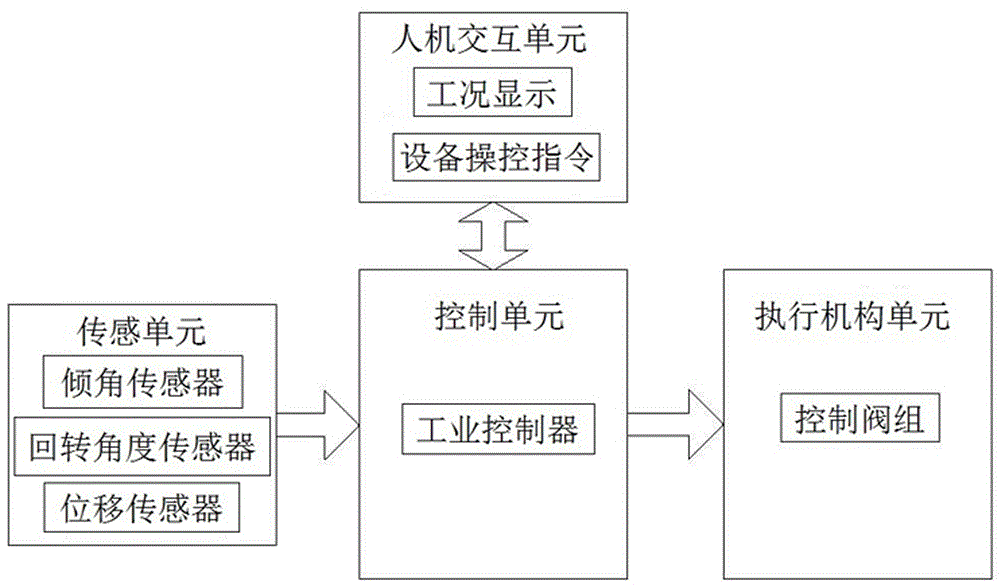

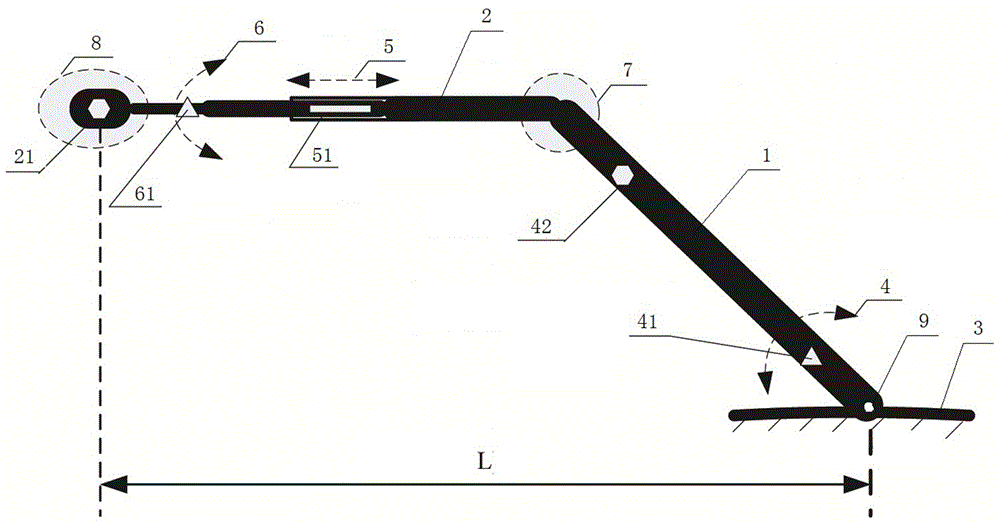

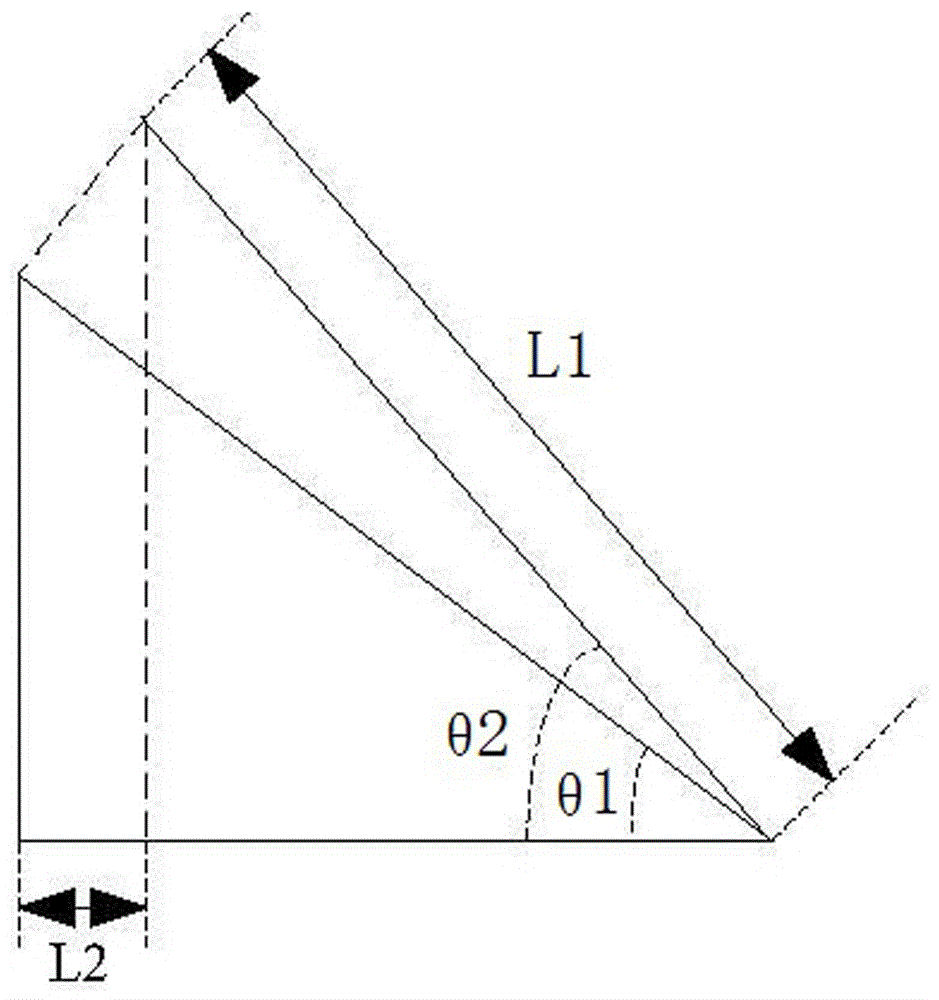

[0029] like figure 1 As shown in the figure, the present invention is a multi-mode automatic control device for the attitude of the end boom of the tunnel multi-arm and multi-joint operation equipment, which is based on the existing multi-arm and multi-joint operation equipment, A rotation angle sensor and an inclination sensor are installed on the basic boom and movable boom to measure the rotation angle value of the slewing mechanism and the angle between each boom and the horizontal plane; a displacement sensor and a rotation angle sensor are installed on each movable boom to measure The telescopic length value of the telescopic mechanism and the rotation angle value of the slewing mechanism. On the basis of the displacement and angle signals collected by each sensor, the control unit combines the operator's manipulation instructions transmitted by the human-computer interaction unit to process and calculate to output control instructions. The vertical distance between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com