A metal removal device for waste plastic processing

A waste plastic and rejecting device technology, which is applied in the direction of plastic recycling, mechanical material recycling, recycling technology, etc., can solve the problem of unsatisfactory effects of metal rejecting devices, and achieve the effect of improving the rejecting effect, ensuring the rejecting effect, and facilitating separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

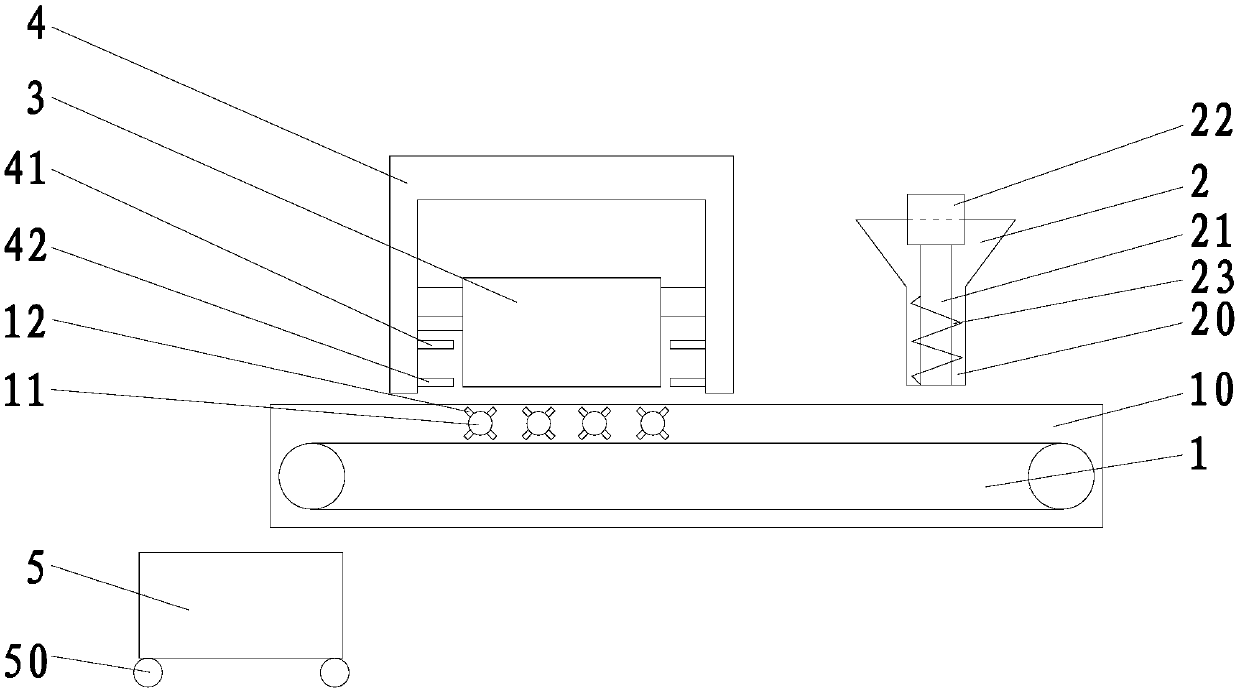

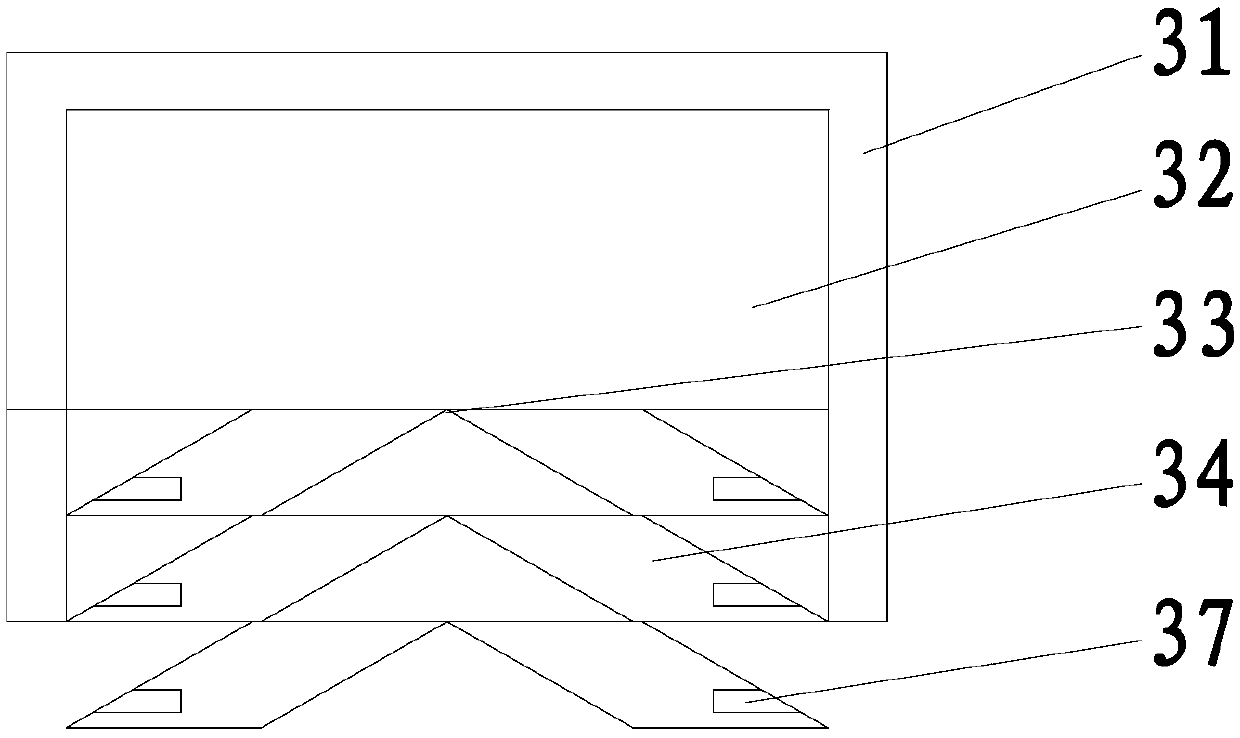

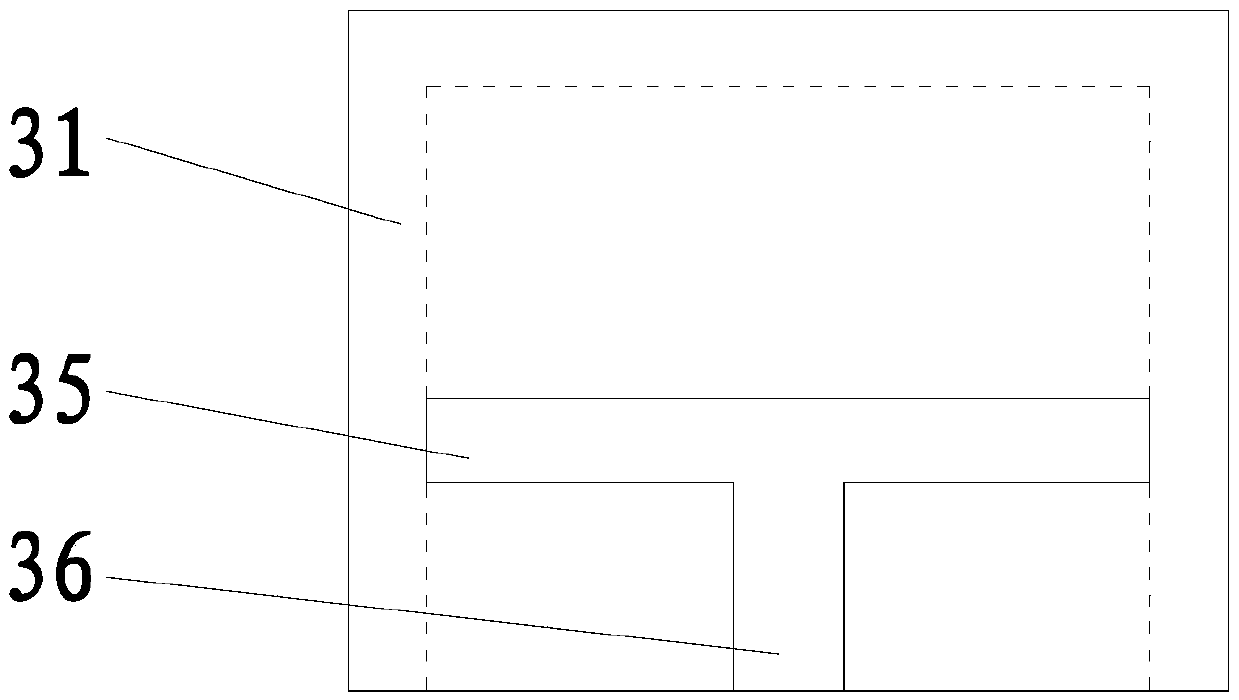

[0018] refer to Figure 1-5 , a metal rejecting device for waste plastic treatment in the present invention, comprising a conveyor belt 1, a feed hopper 2, an adsorption device 3, a mounting frame 4, a receiving box 5, a first telescopic arm 41, and a second telescopic arm 42, the conveyor belt 1 A material receiving box 5 is provided below the discharge end, and a number of lockable rollers 50 are provided at the bottom of the material receiving box 5. A feed hopper 2 is provided above the feed end of the conveyor belt 1, and a discharge hopper 2 is provided at the bottom of the feed hopper 2. The feed pipe 20 and the feed hopper 2 are provided with a vertically downward rotating shaft 21, the rotating shaft 21 is provided with crushing leaves 23 that can crush plastics, the upper end of the rotating shaft 21 is connected with a power unit 22, and the conveyor belt 1 is provided above There is an adsorption device 3, the adsorption device 3 is located between the feed hopper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com