Magnetic core clamping device

A clamping device and magnetic core technology, which is applied in the field of magnetic core clamping devices, can solve problems such as poor pressure control, easy loosening of the magnetic core, and broken core clamping, so as to achieve the effect of easy control of pressure and increase in yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

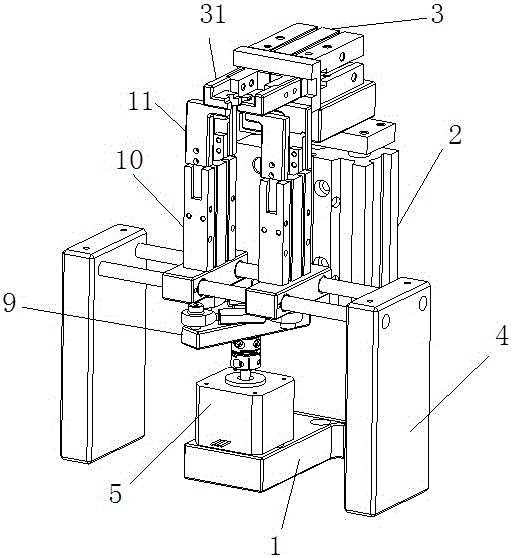

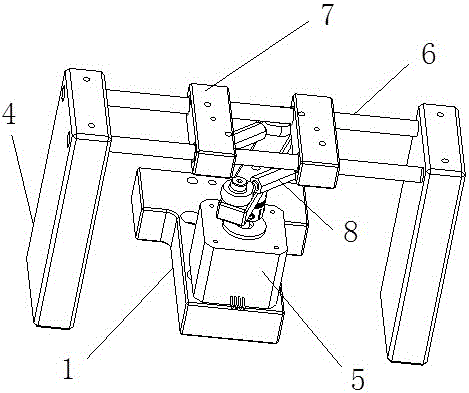

[0017] The present invention will be further described now in conjunction with accompanying drawing. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

[0018] Such as figure 1 figure 2 As shown, a magnetic core clamping device includes a base 1, the rear end of the base 1 is provided with a lift cylinder 2, and the push rod of the lift cylinder 2 is provided with a main finger cylinder 3 placed horizontally forward, and two of the main finger cylinder 3 The main air jaws are respectively connected with main splints, and the main finger cylinder 3 drives the two main splints to perform clamping movement in the horizontal left and right directions. The injection molded parts and the magnetic core are placed between the two main splints, and a rest groove is formed on the main splint to prevent the injection molded parts and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com