Intermediate frequency heating device for internal film coating of steel-plastic composite pipe

A technology of steel-plastic composite pipe and heating device, which is applied in the field of metallurgy, can solve the problems of substandard pressure, decreased film quality, instability, etc., and achieve the effects of significant expansion and sealing, scientific design, and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

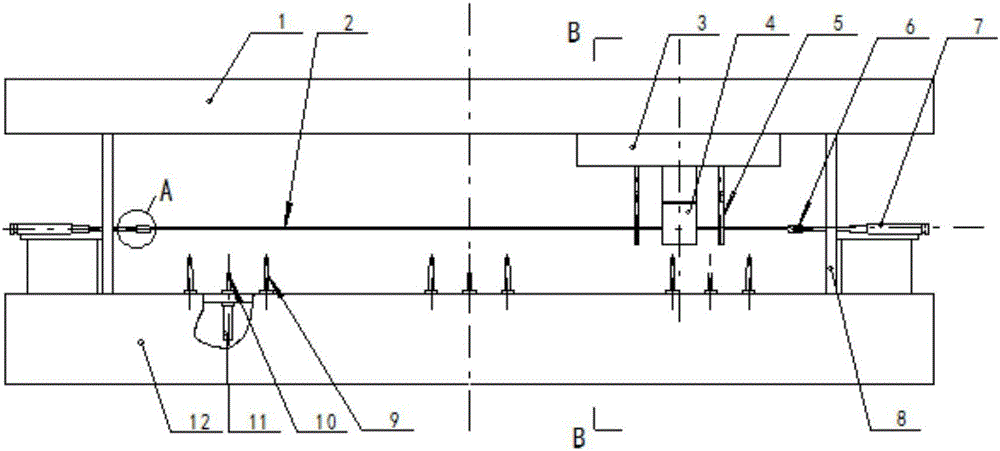

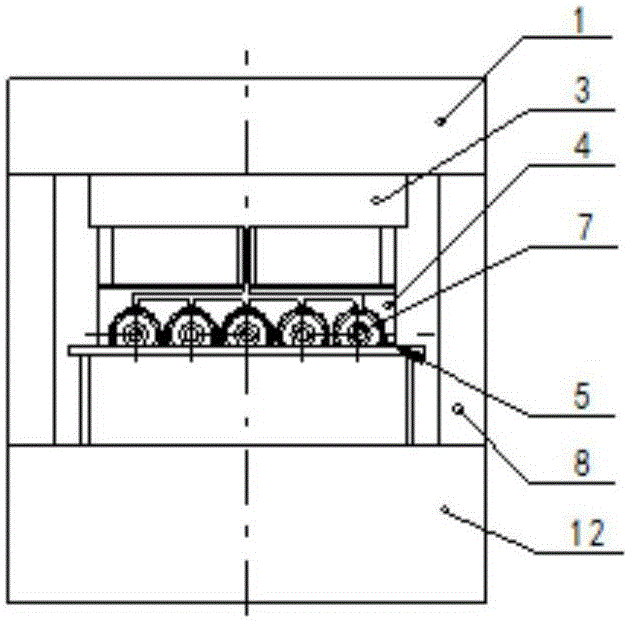

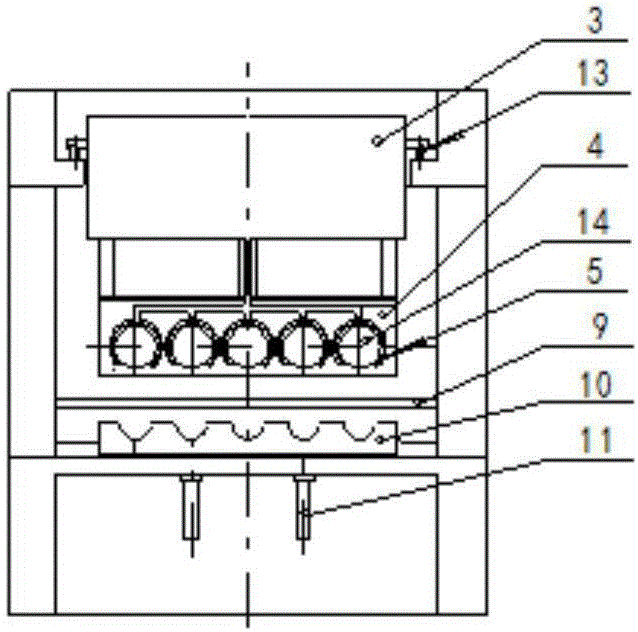

[0025] A steel-plastic composite pipe inner film-coated medium-frequency heating device, including a frame part, a guided mobile heating machine part, a cylinder 7, an inflatable sleeve 6, a fixed guide rail 9, a movable top plate 10, and an oil cylinder 11. The frame part is a base 12, a column 8, and a beam 1 constitutes a square frame, the guiding mobile heating part includes a mobile suspension beam 3, an intermediate frequency heating body 4, and a cooling ring 5. The mobile suspension beam travels horizontally and longitudinally on the beam through the guide rail 13 and is hoisted on the lower bottom surface of the mobile suspension beam. The intermediate frequency heating body, the intermediate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com