Gear type pencil tip thickness adjusting and broken core pushing-out integrated mechanism and pencil sharpener

A gear and pen tip technology, applied in the field of integrated mechanism, can solve the problem that the pencil sharpener cannot realize rapid broken core and push out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

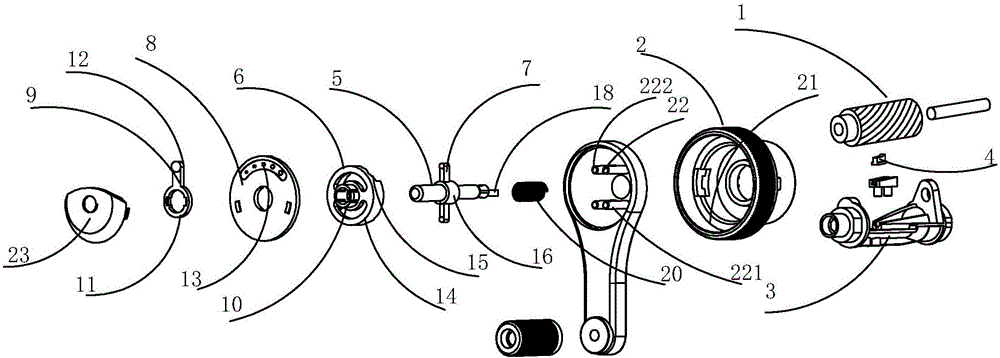

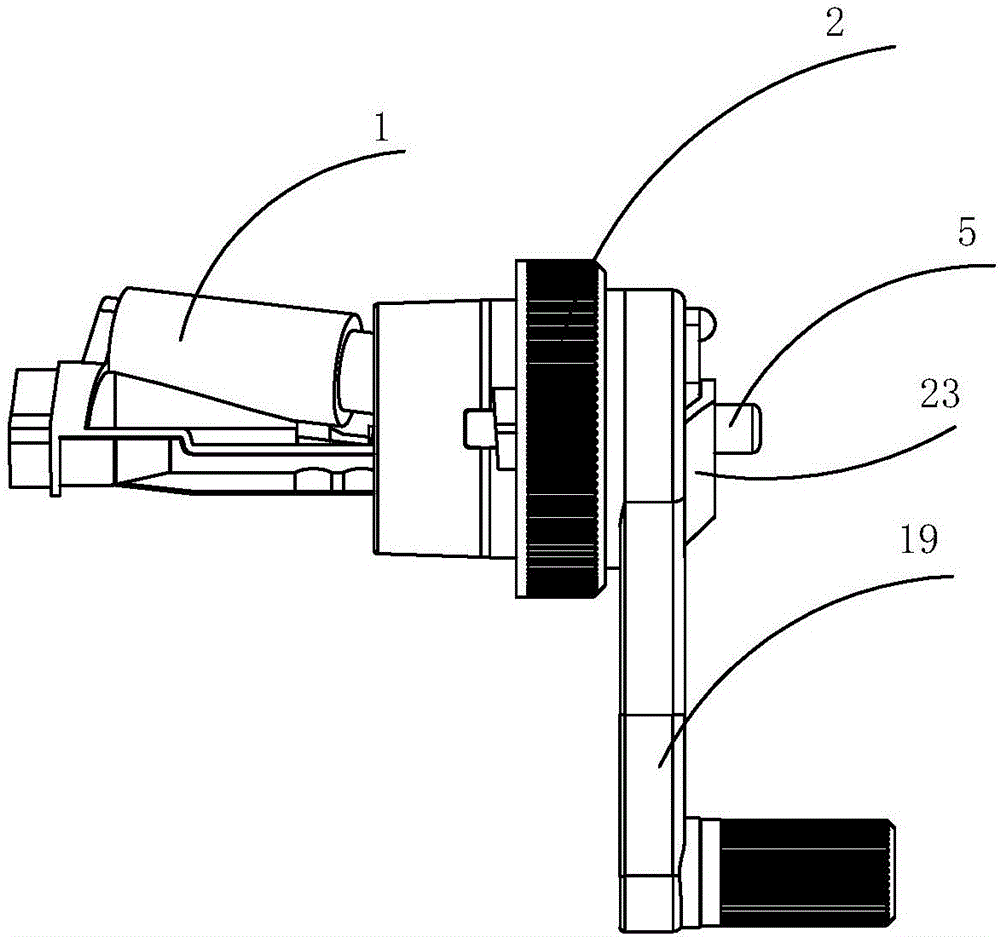

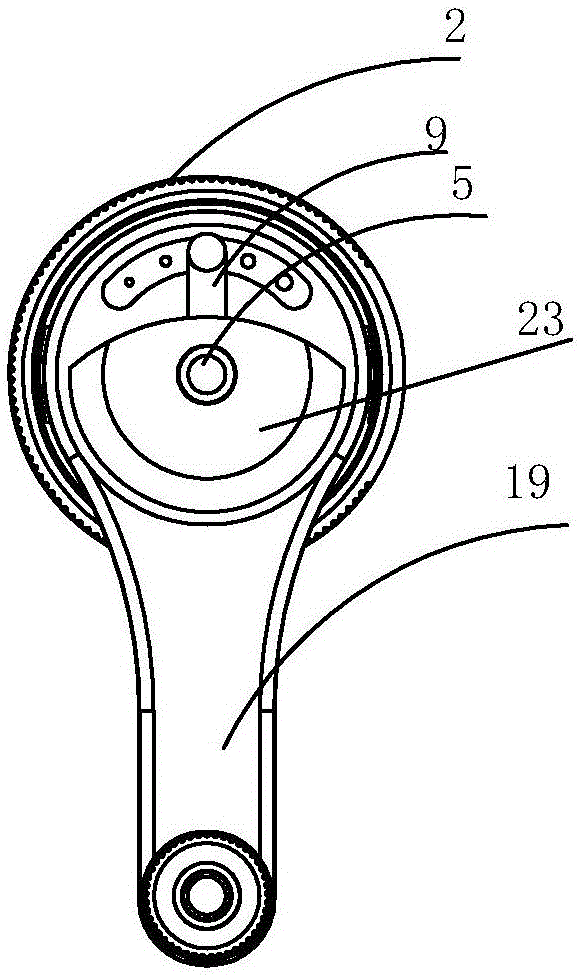

[0028] A pencil sharpener, including a box body, a hob assembly 1, a wheel base 2, and an integrated mechanism for adjusting the thickness of a gear-type pen tip and pushing out a broken core, including a sliding stop 4 independently arranged on a tool holder 3, and a shaft only To the telescopic rod 5 and the stepped gear plate 6 that move and can push the sliding stop block 4 forward, the telescopic rod 5 is fixedly provided with at least one gear rib 7 that cooperates with the stepped gear plate 6, and the rocker arm 19 rear cover 8 The outside is provided with a drive part 9 that can rotate the stepped gear plate 6 located inside the rocker cover 8, and the rear end of the telescopic rod 5 stretches out from the rocker cover 8 and is staggered with the drive part 9, so that the rear end of the telescopic rod 5 Exposed outside the rocker co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com