Material transfer device and production system thereof

A transfer device and material technology, which is applied in the direction of transportation and packaging, conveyors, mechanical conveyors, etc., can solve the problems of difficult centralized transfer of products and large manpower consumption, and achieve the effect of saving manpower consumption and improving transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

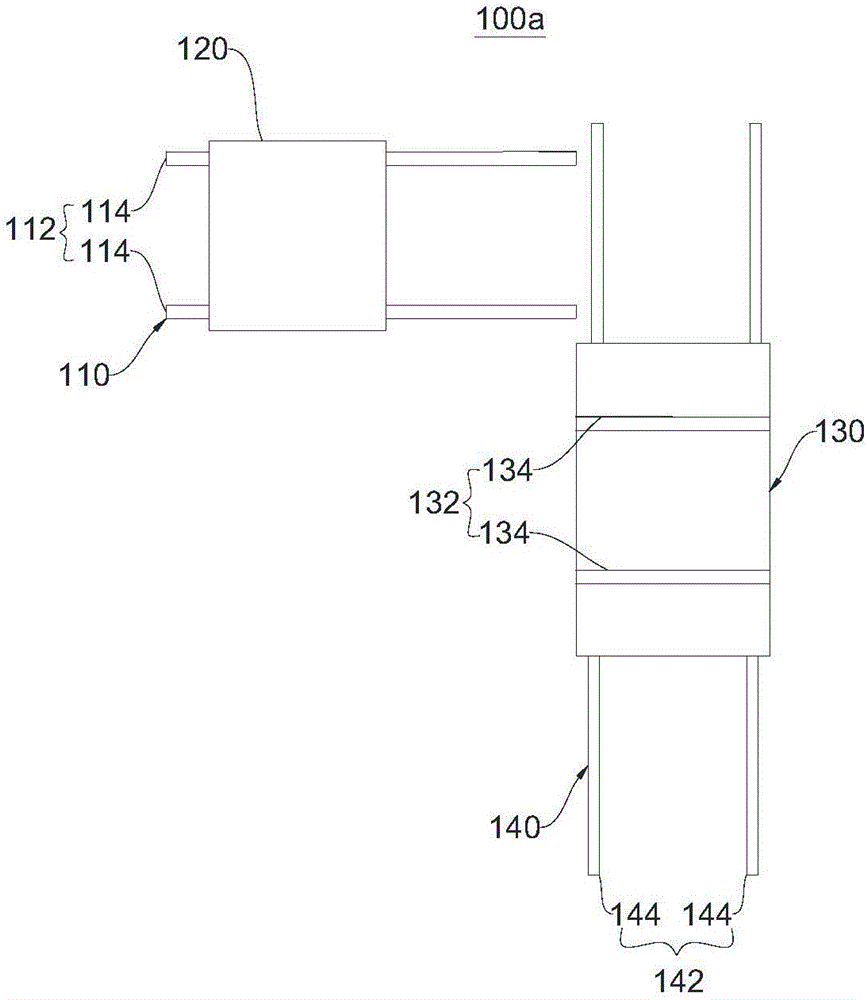

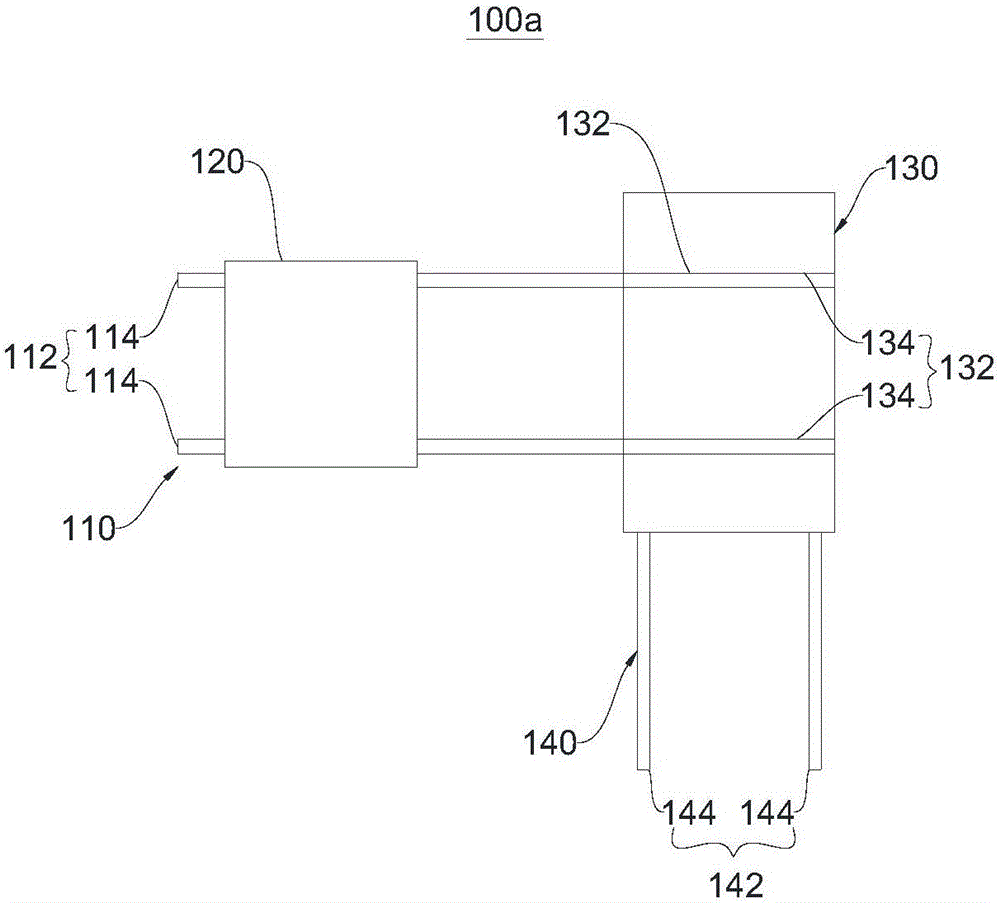

[0036] Please refer to figure 1 with figure 2 , the present invention provides a material transfer device 100a, comprising a first rail 110, a first rail car 120 for carrying materials, a second rail 140 and a second rail car 130 for carrying the first rail car 120, when When the second rail car 130 slides to one end of the first rail 110 , the third slide rail 132 is docked with the second slide rail 142 .

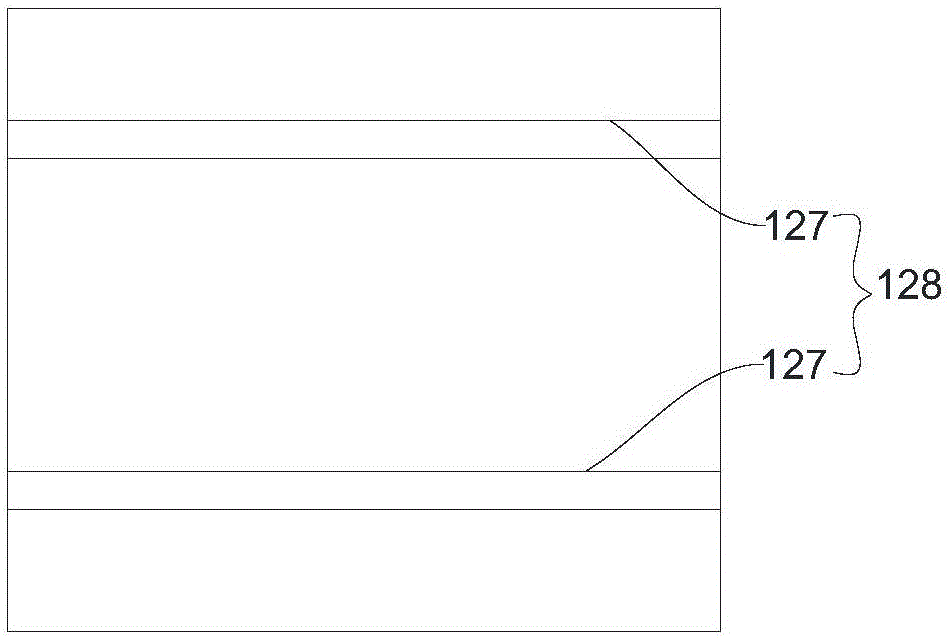

[0037] Further, recombine image 3 with Figure 4, the first track 110 has a first slide rail 112 , and the bottom of the first rail car 120 is provided with a first slide member 128 matched with the first slide rail 112 . The second track 140 has a second slide rail 142 , and the bottom of the second rail car 130 is provided with a second slide member 131 matched with the second slide rail 142 . The second rail car 130 is further provided with a third sliding rail 132 matched with the first sliding member 128 .

[0038] It should be noted that the first rail car 12...

no. 2 example

[0052] The implementation principle and technical effect of the material transfer device 100b provided by the embodiment of the present invention are the same as those of the first embodiment. For a brief description, reference can be made to the corresponding content in the first embodiment for what is not mentioned in this embodiment.

[0053] Please refer to Figure 10 , the material transfer device 100b provided in this embodiment further includes a third rail 150 , and the third rail 150 is detachably connected to one end of the first rail 110 . recombine image 3 , the third track 150 includes two third sliding protrusions 152 arranged in parallel, and the two third sliding protrusions 152 cooperate with the two sliding cavities 127 . One end of the third rail 150 and the first rail 110 is set to be detachably connected, the third rail 150 is placed in the working room, and the third rail 150 can be removed after the first rail car 120 is transported to the working room...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com