rope grip

A rope gripper and gripper block technology is applied in the field of rope grippers, which can solve the problems of reduced action sensitivity and reliability of the rope gripper, and achieve the effects of improving movement flexibility, reducing friction coefficient and reducing resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

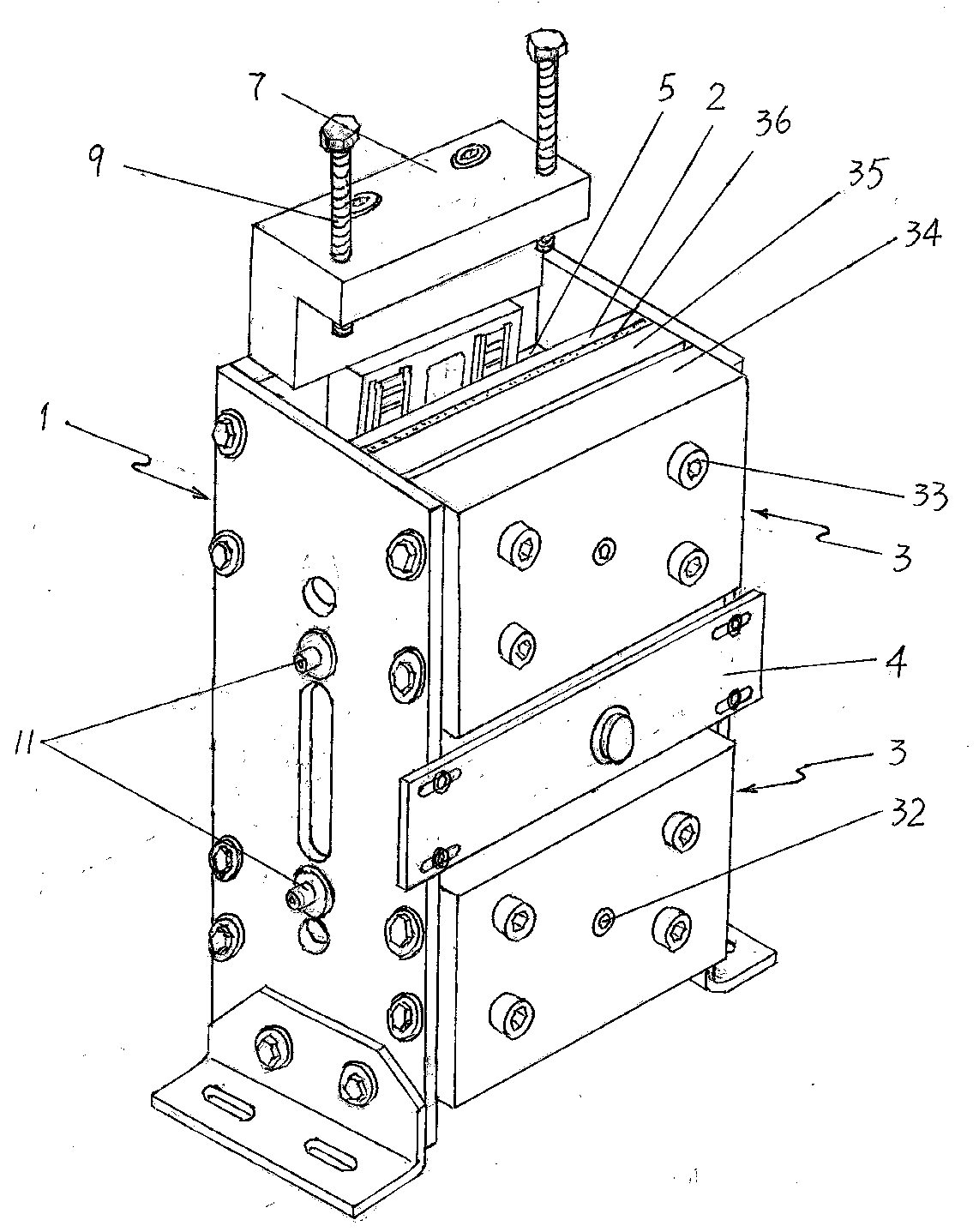

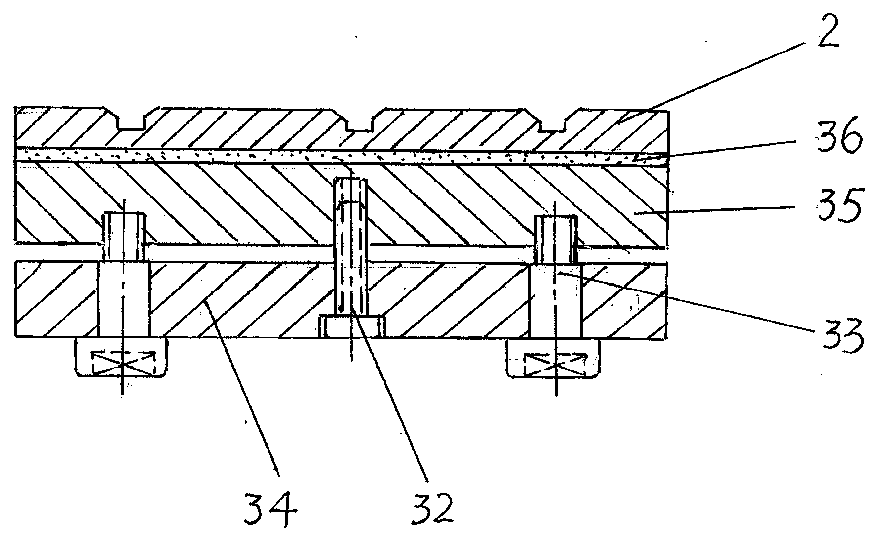

[0025] Such as figure 1 As shown, the rope gripper of the present invention includes a frame 1, two fixed clamping blocks 3 fixed on the frame, and a movable clamping block 5 opposite to the fixed clamping blocks and arranged in the center. Friction plates 2 ( Figure 4 , Figure 5 ); the longitudinal gap formed between the movable clamping block 5 and the fixed clamping block 3 is the rope passage for the traction wire rope to pass through.

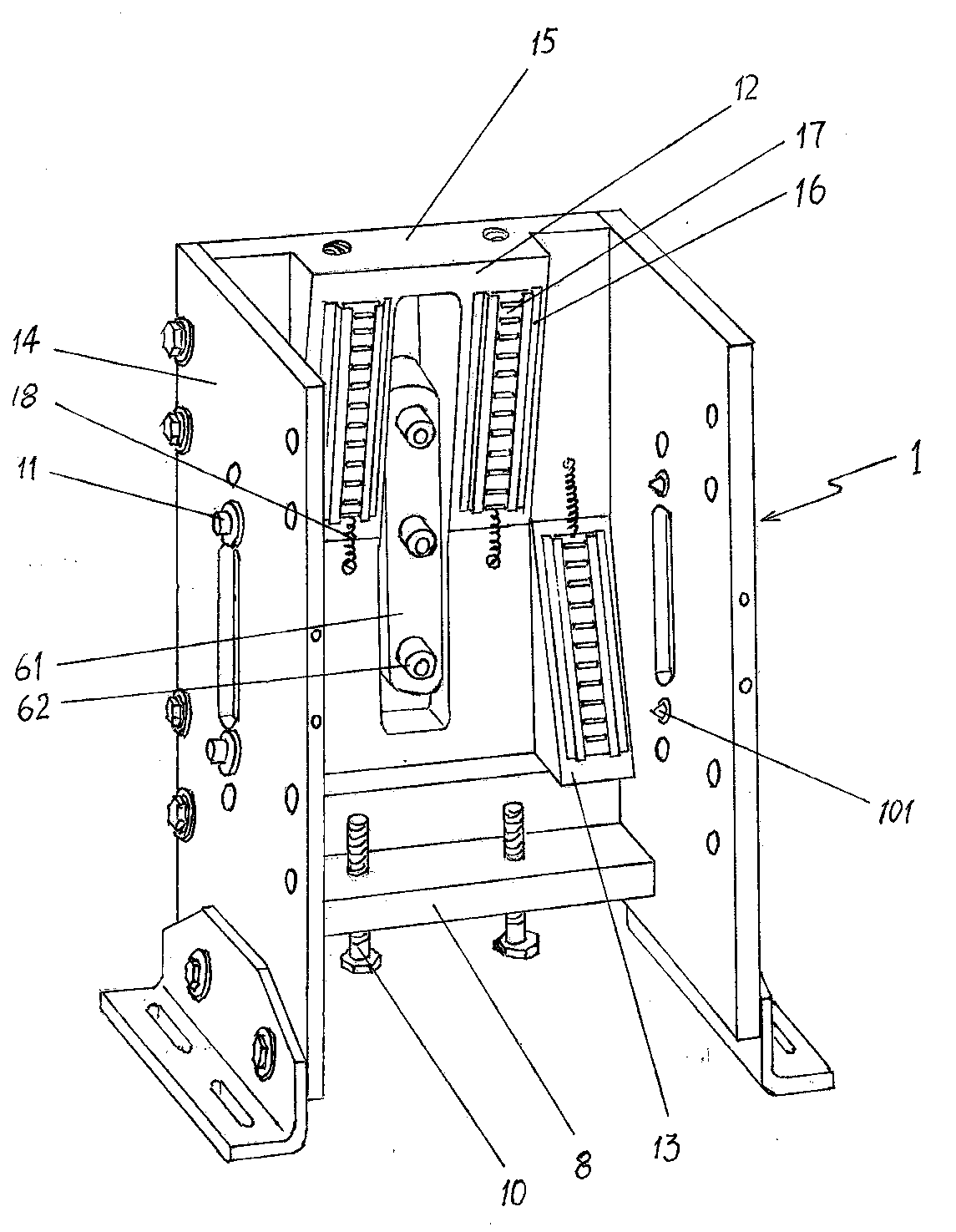

[0026] Such as figure 2 As shown, the frame 1 is a vertical trough-shaped body surrounded by two side plates 14 and a rear end plate 15 located between the two side plates, and an upper wedge-shaped upper part of the inner wall of the rear end plate 15 is centered. The upward stop surface 12 is symmetrically provided with two downward wedge-shaped downward stop surfaces 13 on both sides of the lower inner wall of the rear end plate 15, and the inner edge of the downward stop surface 13 is closely adjacent to the outer edge of the upw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com