A flip-type template detection device

A technology for template detection and plate flipping, which is used in optical testing for flaws/defects, hoisting devices, electric components, etc., can solve problems such as affecting physical health, reducing work efficiency, and fatigue of observers, reducing work difficulty and improving work. Efficient, precise flip angle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

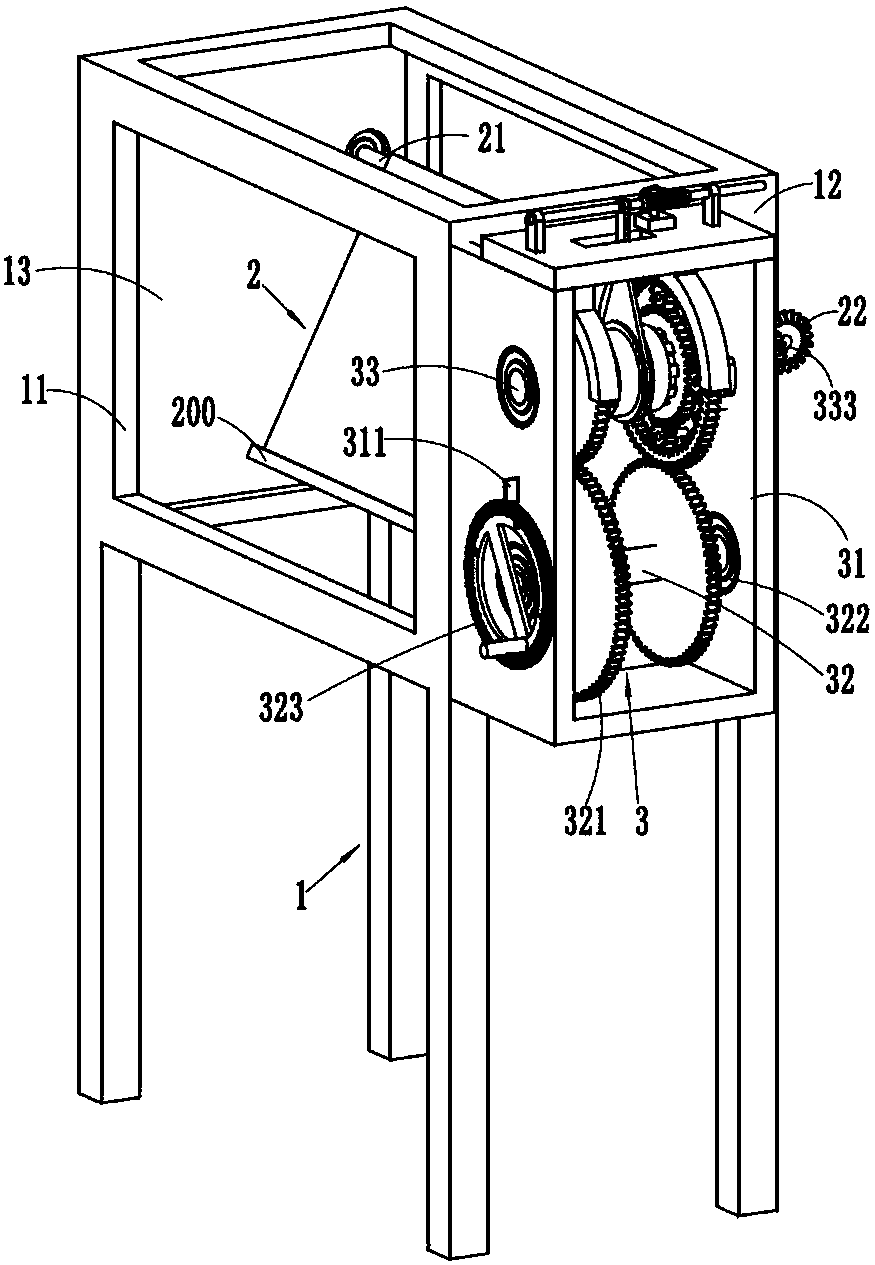

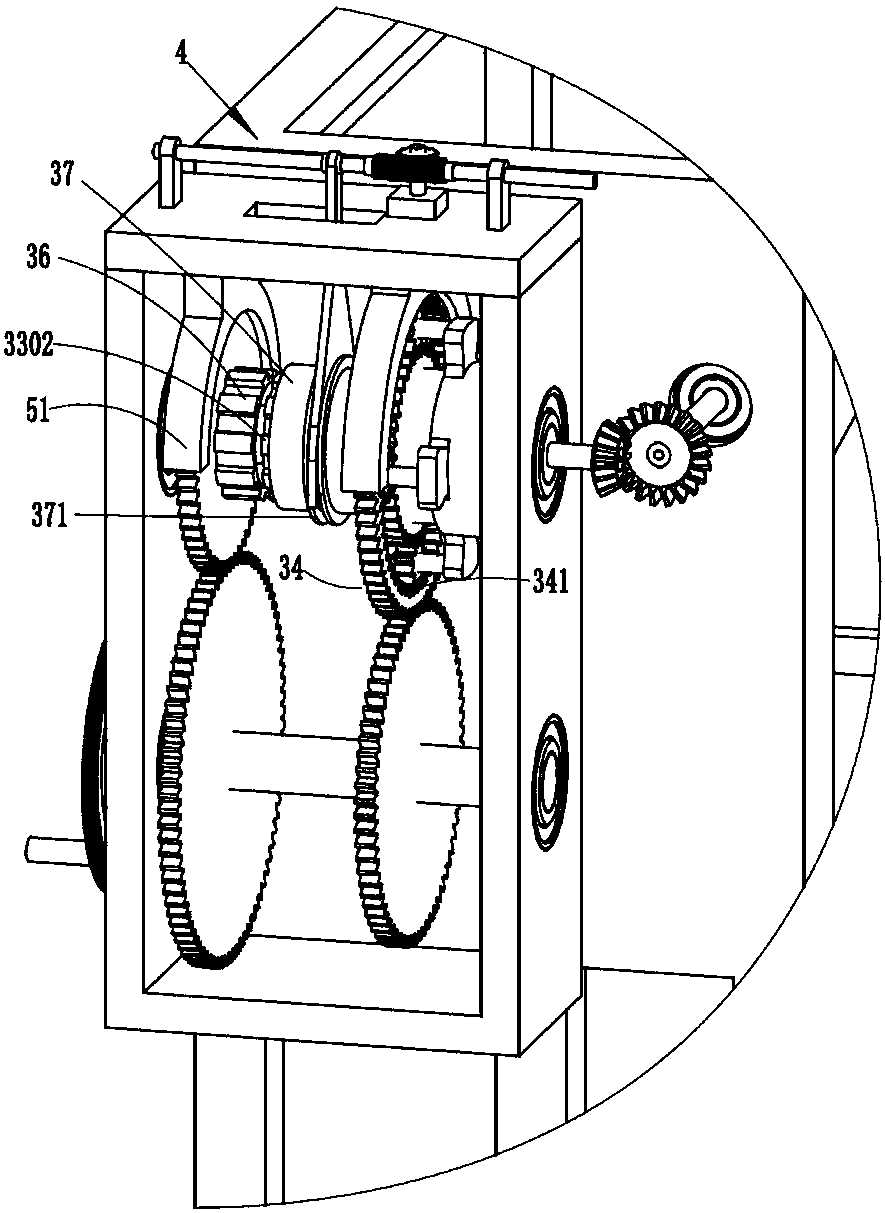

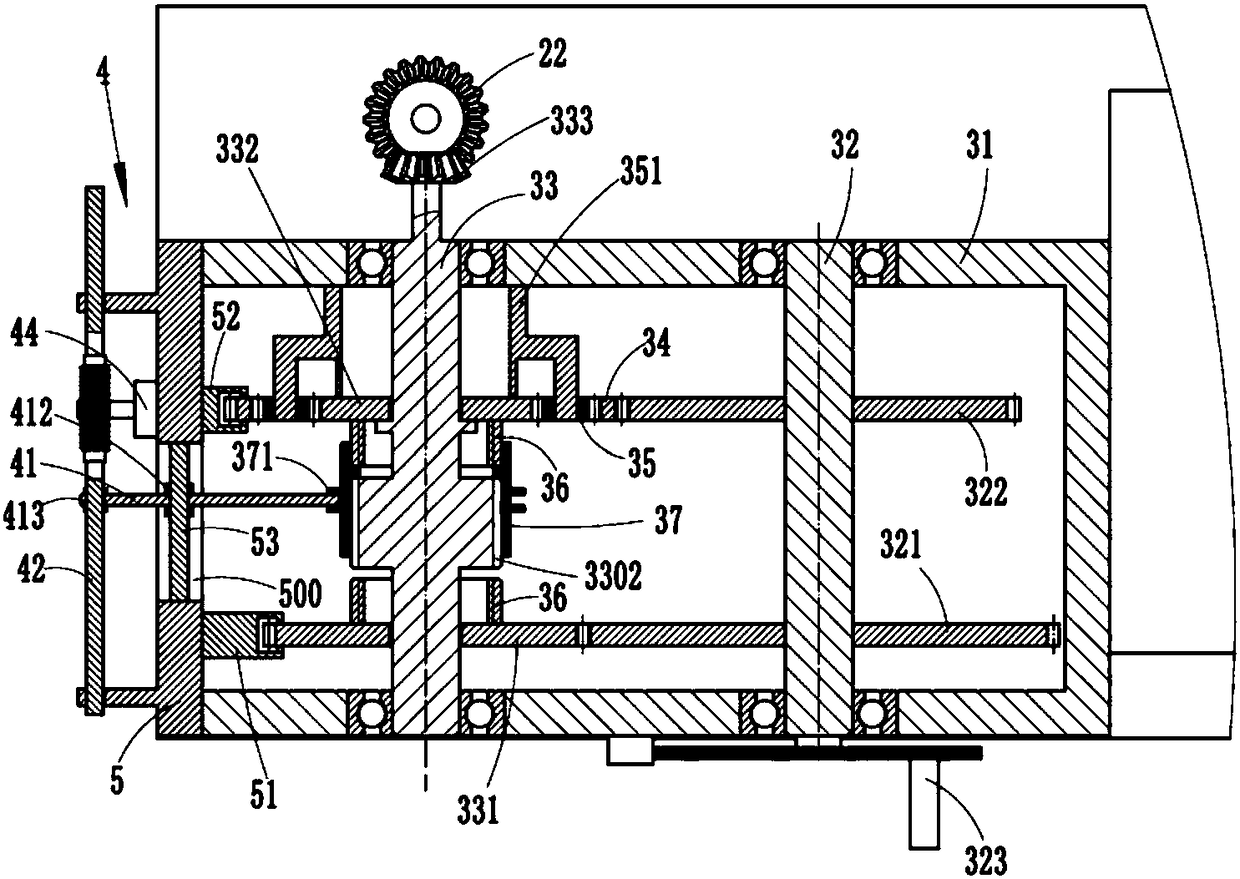

[0023] Examples, see e.g. Figure 1 to Figure 4 As shown, a flip-type template detection equipment includes a detection frame 1, a flip plate 2 and a flip plate drive mechanism 3, a detection window 11 is provided on the front side of the detection frame 1, and the flip plate 2 is placed in the detection The inside of the frame 1 is hinged on the detection frame 1, the flip plate 2 is positioned behind the detection window 11, the base frame 31 of the flip plate drive mechanism 3 is fixed on the right side plate 12 of the detection frame 1, and the flip plate drive mechanism The small bevel gear 333 of 3 meshes with the large bevel gear 22 that is installed on the right side of the turnover plate 2.

[0024] Furthermore, a turning shaft 21 is fixedly connected to both sides of the upper end of the turning plate 2, and the two turning shafts 21 are respectively hinged on the left side plate 13 and the right side plate 12 of the detection frame 1 through bearings. The side turn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com