A rubber powder composite modified asphalt composition and its preparation and application

A technology of composite modified asphalt and rubber powder, which is applied in the direction of building construction, on-site coagulation pavement, roads, etc., can solve the problems of high production cost, high reaction temperature, long shearing time, etc., to avoid reaction The effect of temperature, meeting performance requirements, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0042] According to the ratio of the rubber powder composite modified asphalt composition in the present invention, a certain amount of sodium dibutyl phosphate and rubber powder are added to the asphalt, and the mixture is stirred for 60-120 minutes at 180-195°C. Then add a certain amount of styrene-butadiene-styrene block copolymer under the condition of 175~185℃ and cut for 30~60 minutes by colloid mill or high-speed shear emulsifier, and continue to the condition of 175~185℃ Add a certain amount of tetramethylthiuram disulfide, stir and react for 75-300 minutes to prepare modified asphalt. Among them, the asphalt is Esso No. 70 asphalt. The weight percentages of rubber powder are 5%, 10%, 15%, and 20% respectively; the weight percentages of sodium dibutyl phosphate are 0.5%, 1.0%, 1.5%, 2.5% respectively; styrene-butadiene The weight percentage of the ene-styrene block copolymer is 2%; the weight percentage of the tetramethylthiuram disulfide is 0.2%.

[0043] The formula, ...

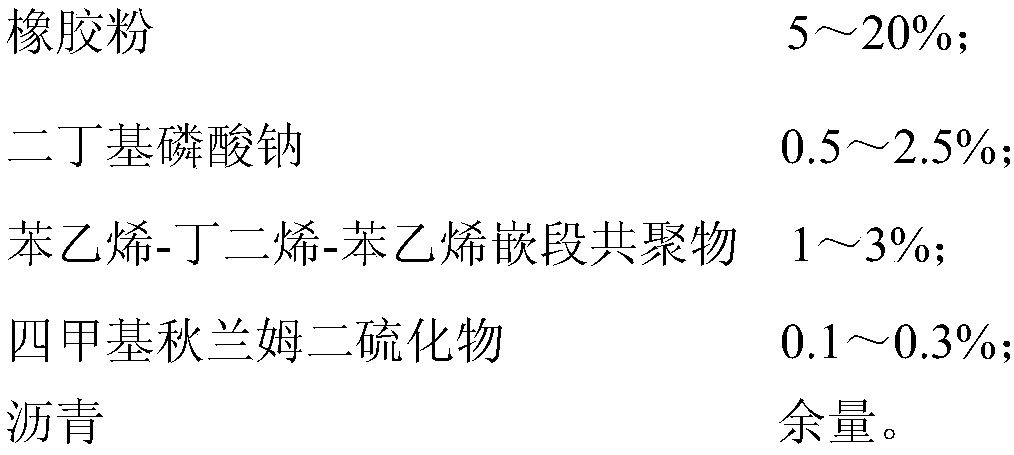

Embodiment 5-7

[0049] Stir different weight percentages of sodium dibutyl phosphate and 20% 60 mesh rubber powder at 190°C for 120 minutes, add 2% styrene-butadiene-styrene block copolymer at 180°C and shear for 30 minutes. Continue to add 0.2% tetramethylthiuram disulfide at 180°C and stir for 120 minutes. The test results of different weight percentages of sodium dibutyl phosphate are shown in Table 2.

[0050] From the test data results in Table 2, the addition of sodium dibutyl phosphate improves the softening point and ductility of rubber powder modified asphalt at 5°C; the storage stability is significantly improved; no dibutyl phosphoric acid is added Sodium modified asphalt cannot be processed due to its excessive viscosity.

[0051] Table 2 Effect of sodium dibutyl phosphate on the performance of rubber powder modified asphalt

[0052]

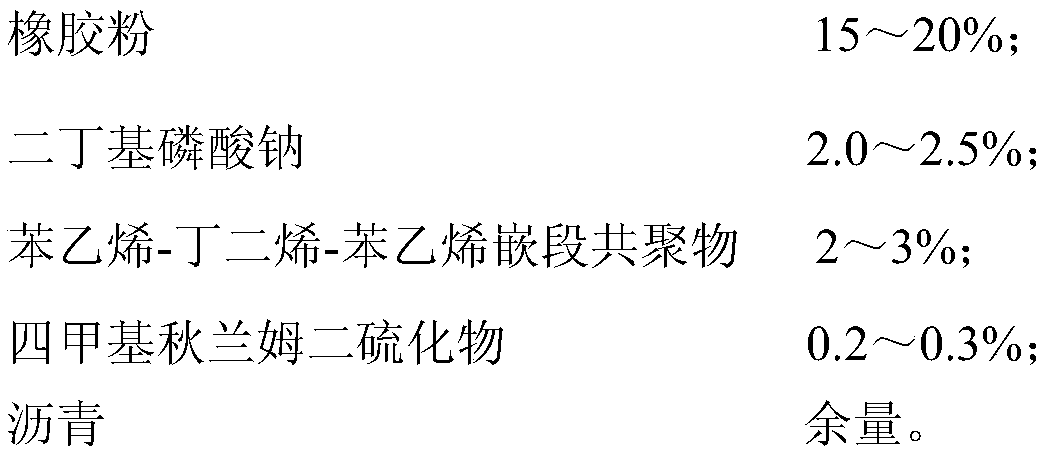

Embodiment 8-13

[0054] Stir 2.5% sodium dibutyl phosphate and 20% 40 mesh rubber powder at 190°C for 120 minutes, add different weight percentages of styrene-butadiene-styrene block copolymer at 180°C and shear for 30 minutes. Continue to add tetramethylthiuram disulfide with different weight percentages at 180°C and stir for 120 minutes. The test results after adding different weight percentages of styrene-butadiene-styrene block copolymer and tetramethylthiuram disulfide are shown in Table 3:

[0055] Table 3 Research on the influence of processing temperature on the performance of rubber powder modified asphalt

[0056]

[0057] From the results of the above test data, increasing the content of styrene-butadiene-styrene block copolymer and tetramethylthiuram disulfide can increase the softening point of the composite modified asphalt and increase the ductility at 5°C. . And by compounding the styrene-butadiene-styrene block copolymer, the problem of easy segregation in high temperature storag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap