modified asphalt composition

A technology of modified asphalt and composition, which is applied in the direction of building structure, on-site paved coagulation pavement, road, etc., to achieve the effect of feasible preparation method, improved construction performance and meeting performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Further, the preparation method of the rubber powder modified asphalt comprises the steps of: adding rubber powder to the base asphalt at a reaction temperature above 200°C, using a desulfurization degradation process to promote the dissolution of the rubber powder in the base asphalt phase, Obtain rubber powder modified asphalt.

[0031] Further preferably, the preparation method of the rubber powder modified asphalt comprises the steps of: adding rubber powder to the base asphalt at a reaction temperature of 240-280°C and reacting for 4-8 hours; using a desulfurization degradation process to promote the rubber powder Dissolved in the matrix asphalt phase to obtain rubber powder modified asphalt.

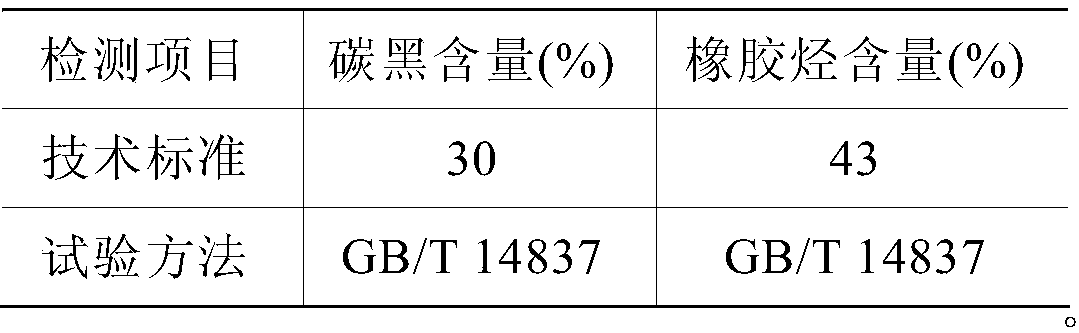

[0032] Further, the rubber hydrocarbon content of the rubber powder is >40% (the test method for the rubber hydrocarbon content of the rubber powder adopts GB / T14837). Low rubber hydrocarbon content will lead to the problem of poor adhesion of the prepared rubber powder mod...

Embodiment 1~4

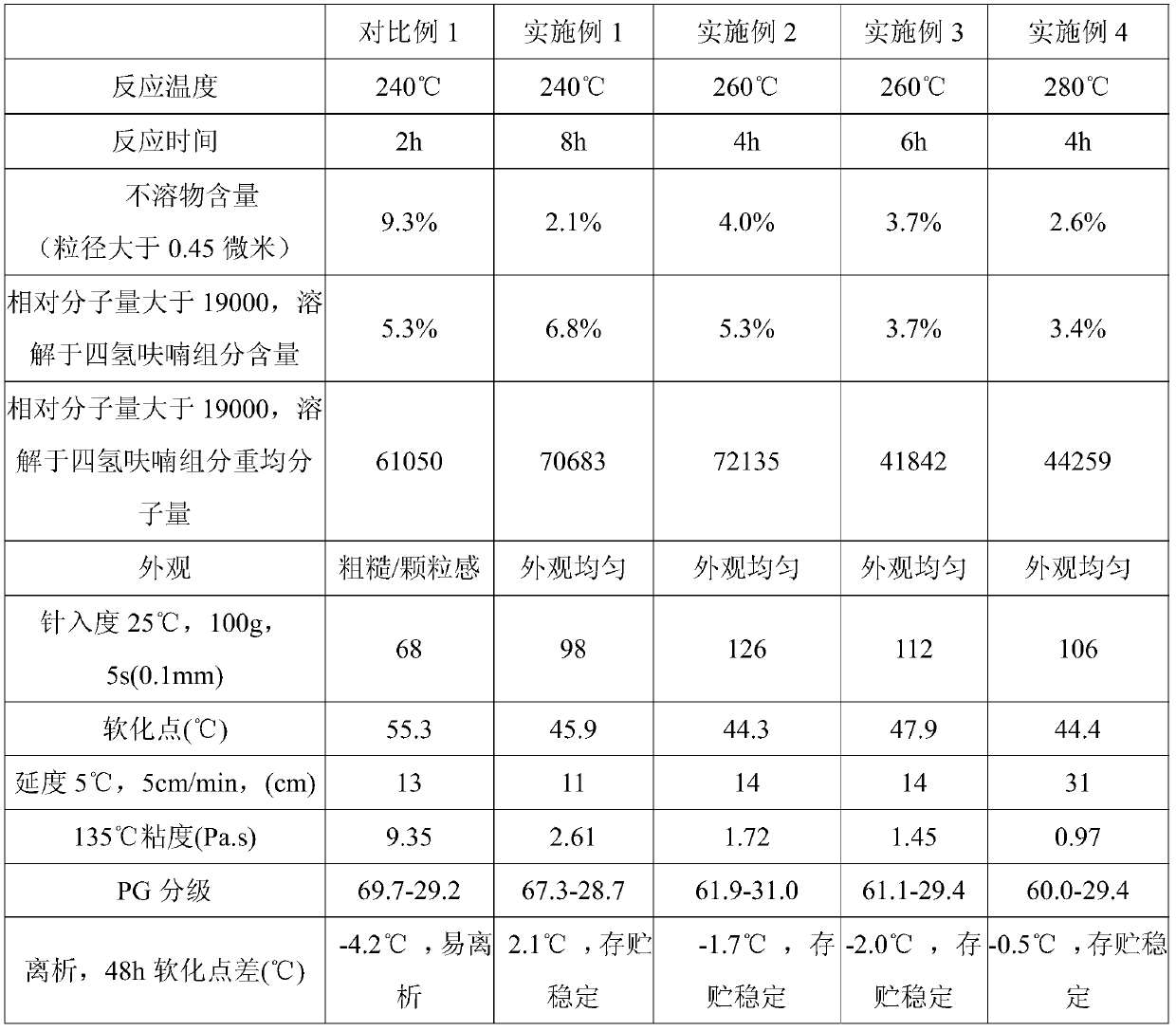

[0052] The formula of rubber powder modified asphalt is A: rubber powder (30 mesh) weight percent 20wt%, asphalt balance.

[0053] The preparation method of rubber powder modified asphalt: under different reaction conditions (reaction temperature, reaction time), rubber powder is added in matrix asphalt, use desulfurization degradation process to promote rubber powder to dissolve in matrix asphalt phase, obtain embodiment respectively 1-4 rubber powder modified asphalt. The test results are shown in Table 1:

[0054] Table 2 Technical indicators of rubber powder modified asphalt prepared under different reaction conditions

[0055]

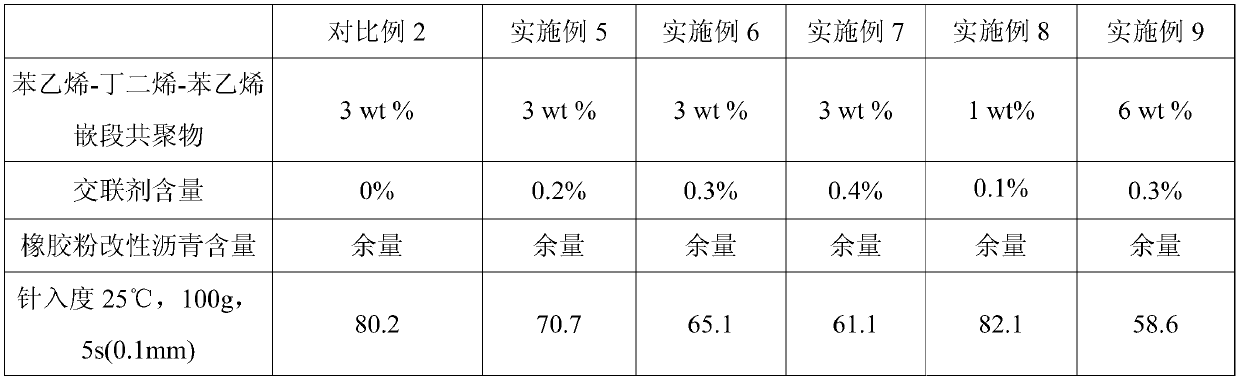

Embodiment 5~9

[0061] The rubber powder modified asphalt prepared in Example 1 was used. Then add 3wt% styrene-butadiene-styrene block copolymer at 180°C, shear for 30 minutes by a colloid mill or a high-speed shear emulsifier, and continue to add different amounts of crosslinking agents and stir for 120 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap