Flushing valve provided with connecting rod type transmission mechanism

A technology of transmission mechanism and flush valve, applied in the field of sanitary ware, can solve the problems such as the limitation of lifting position, and achieve the effect of reducing the torsional moment and reducing the opening force value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

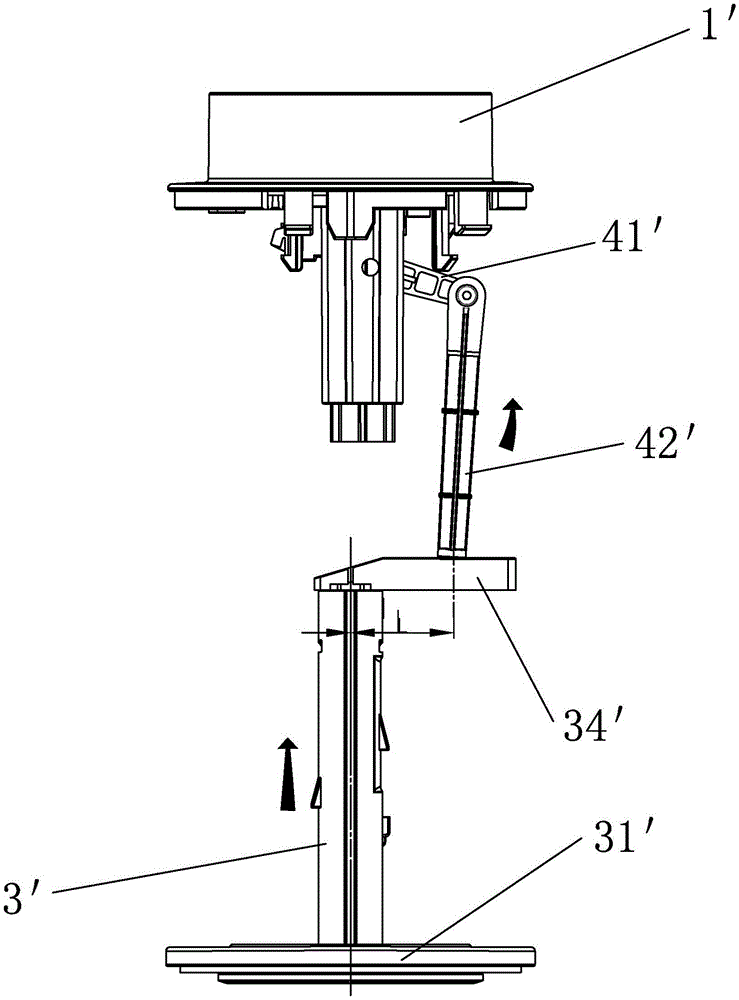

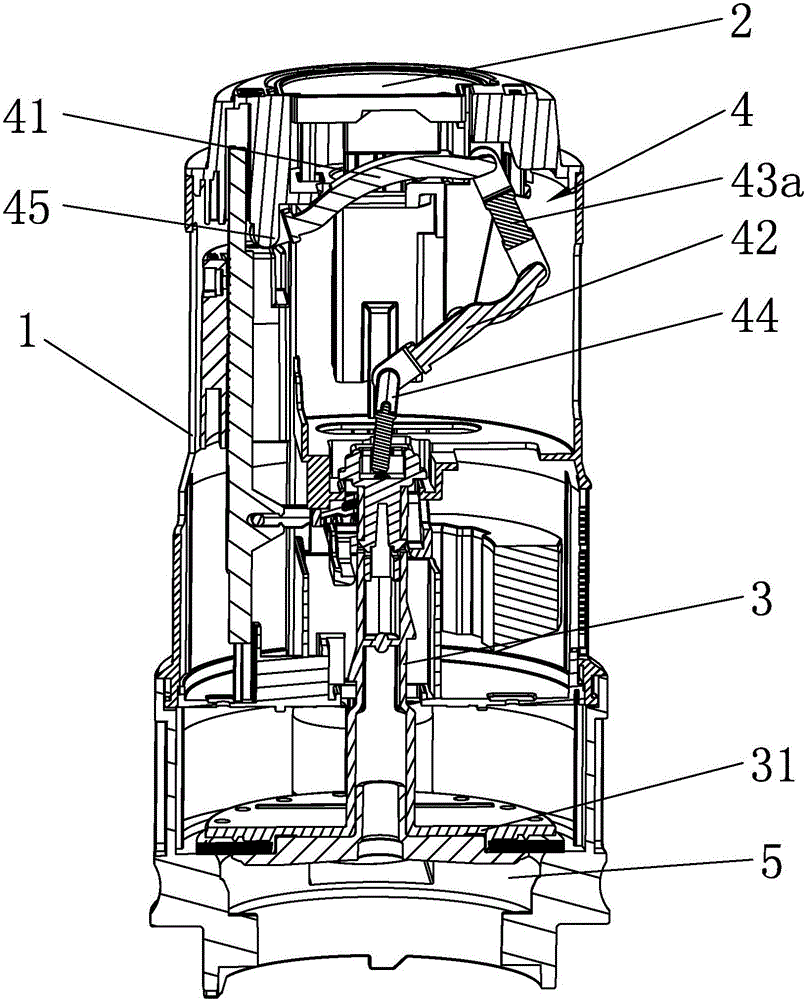

[0033] Such as Figure 2 to Figure 4 , Figure 2 to Figure 4 A flush valve with a link-type transmission mechanism according to the first embodiment of the present invention is shown, which includes a valve body 1, an actuating element 2, a riser pipe 3 and a transmission mechanism 4, and the actuating element 2 and the riser pipe 3 are movable In the valve body 1, the starting element 2 of this embodiment is a button, and the button is movably installed in the button seat provided on the top of the valve body 1. Cooperating with the valve disc 31, the actuating element 2 lifts the lift pipe 3 upwards through the transmission mechanism 4 and then drives the valve disc 31 to move upwards to open the drain port 5 of the flush valve to realize drainage. The transmission mechanism 4 at least includes a connecting rod I41 and a connecting rod II42. The connecting rod I41 is in transmission cooperation with the starting element 2. The connecting rod II42 is used to lift the riser 3...

no. 2 example

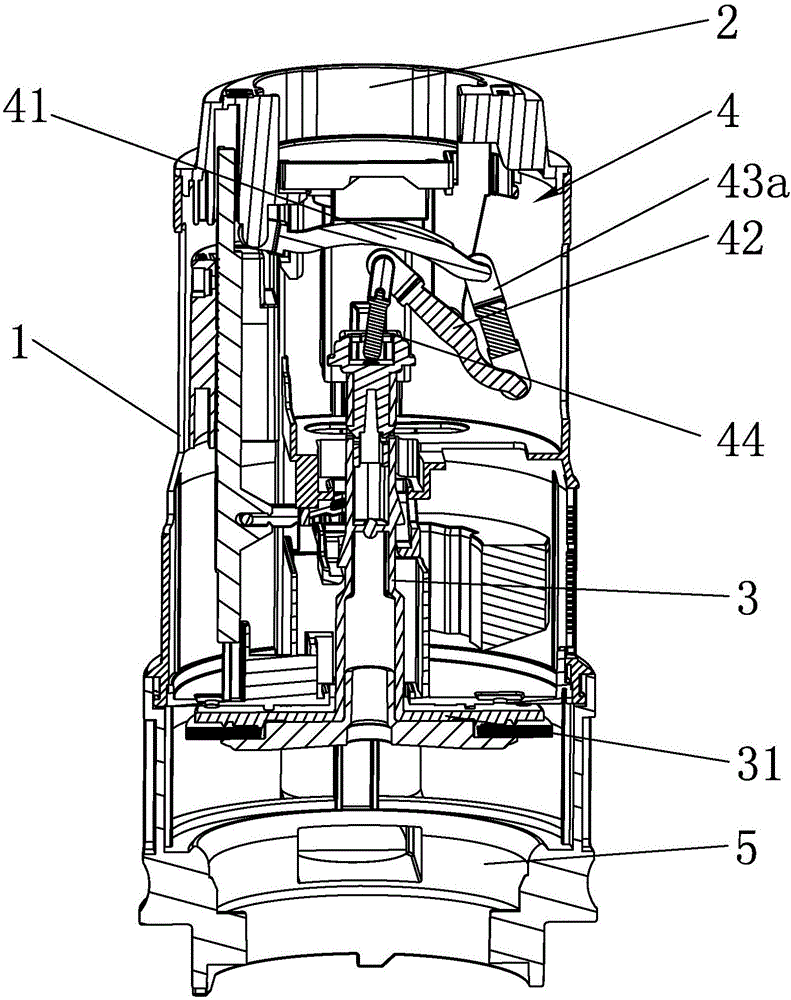

[0042] Such as Figure 5-7 As shown, this embodiment is a simple transformation of the first embodiment, and its difference from the first embodiment is only that: the second end of the push rod 43a of this embodiment slides with the first end of the connecting rod II 42 and Rotation fit, specifically, a chute 411 is provided on the second end of the push rod 43a, the rotating shaft 421 provided at the first end of the connecting rod II 42 extends into the chute 411 and slides and rotates in the chute 411, and the rest of the structure is the same as The first embodiment is the same.

[0043] When draining work, such as Figure 6 and Figure 7 As shown, press the activation element 2, the activation element 2 presses down the connecting rod I41, the connecting rod I41 rotates around its first pivotal part 45 and pushes the push rod 43a, and the push rod 43a pushes down the first end of the connecting rod II42 , so that the first end of the connecting rod II 42 moves from on...

no. 3 example

[0046] Such as Figure 8-10 As shown, this embodiment is a simple transformation of the first embodiment, and its difference from the first embodiment is that this embodiment is not provided with a push rod 43a, specifically, the first end of the connecting rod I41 is pivotally connected to A first pivot joint 45 is formed on the valve body 1, the second end of the connecting rod I41 rotates and slides with the first end of the connecting rod II42, and a slide groove 411 can be optionally provided on the second end of the connecting rod I41, so that The rotating shaft 421 provided on the first end of the connecting rod II 42 extends into the chute 411 and rotates and slides in the chute 411 at the same time, or, in reverse, the first end of the connecting rod II 42 is provided with a chute , so that the rotating shaft provided on the second end of the connecting rod I41 extends into the chute and rotates and slides in the chute at the same time, which realizes the rotation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com