Elevator shaft elevating type operation platform

An operation platform and lifting technology, which is applied in the direction of building structure support, building structure support, building structure support scaffolding, etc., can solve the problems of fastening force, non-turnover, easy to be polluted and damaged, etc., and achieve fast lifting speed , low production cost and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings.

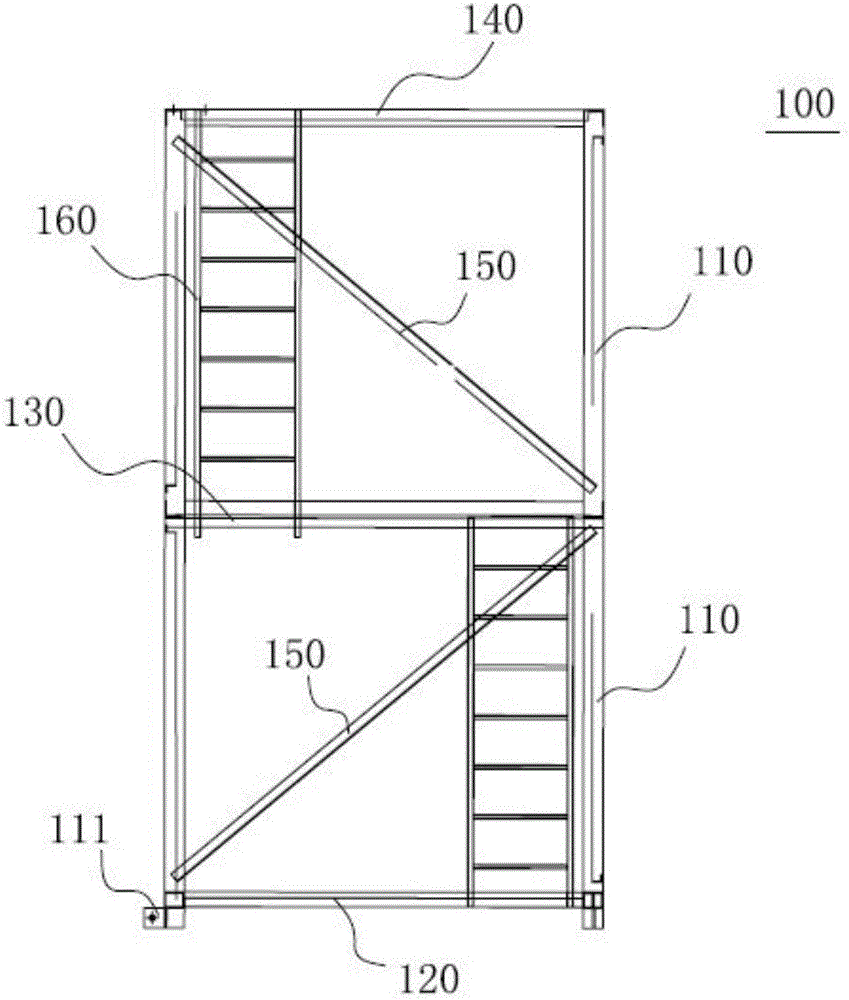

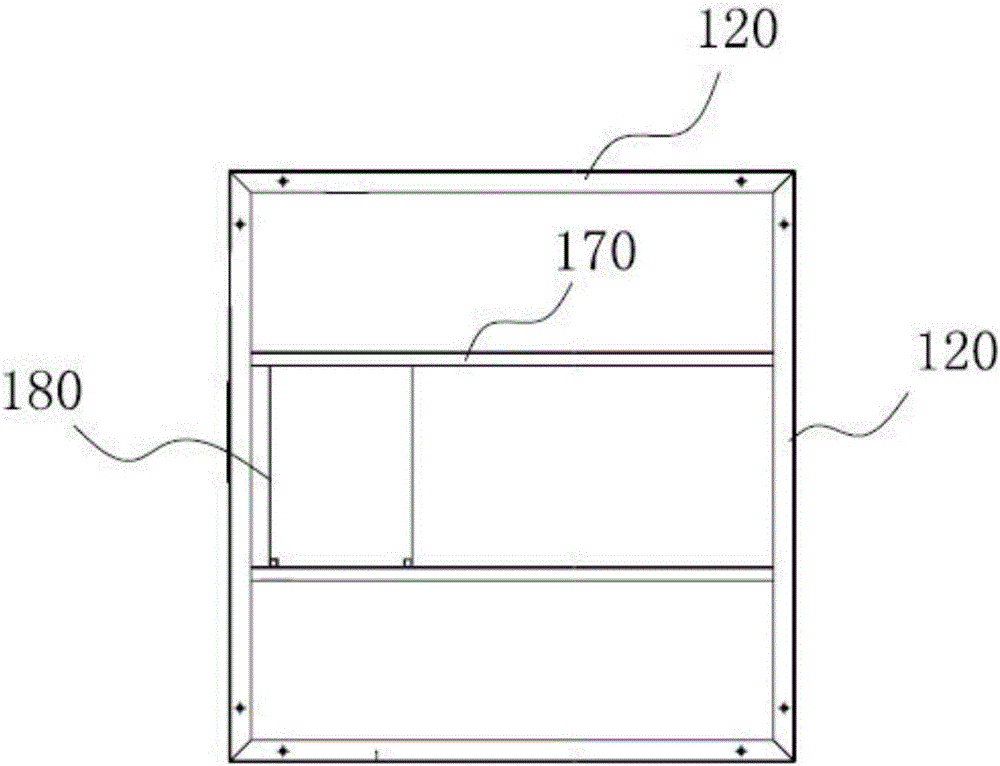

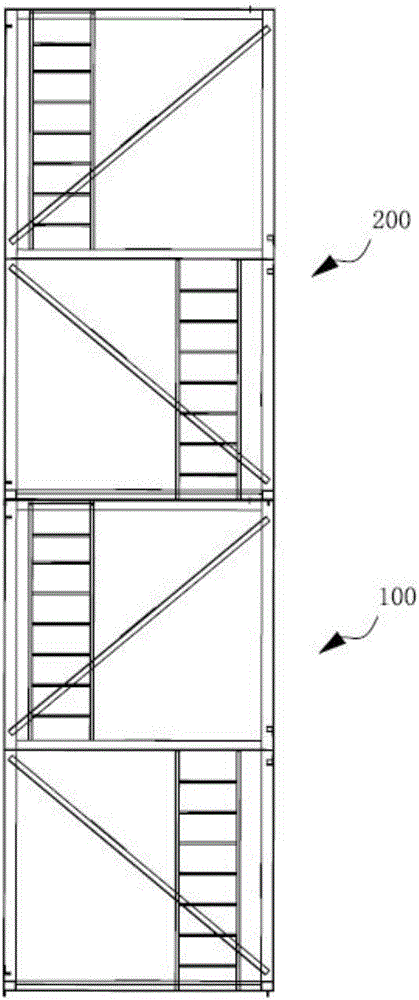

[0030] Such as Figure 1-Figure 3 As shown, the present embodiment provides an elevator hoist operating platform, which includes at least two stacked group frames; the group frame includes a plurality of vertical columns 110, a rectangular first floor bottom frame 120, a Layer bottom frame 130 and third layer bottom frame 140, the bottom end of column 110 is connected at the corner of first layer bottom frame 120, the top of column 110 is connected at the corner of third layer bottom frame 140, the second layer The corners of the bottom frame 130 are connected to the middle of the column 110; between the bottom frame 120 of the first layer and the bottom frame 130 of the second layer, between the bottom frame 130 of the second layer and the bottom frame 140 of the third layer, there are ladders 160 , and the two ladders 160 are arranged alternately; the interior enc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com