Pressure bearing tunnel bottom structure drainage system and construction method thereof

A bottom structure and tunnel technology, applied in drainage, earthwork drilling, mining equipment, etc., can solve problems such as inability to discharge water from the bottom of the tunnel, inability to effectively divert and drain stagnant water, and difficulties in maintenance and management, and achieve large-scale promotion and water seepage Strong effect, good drainage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

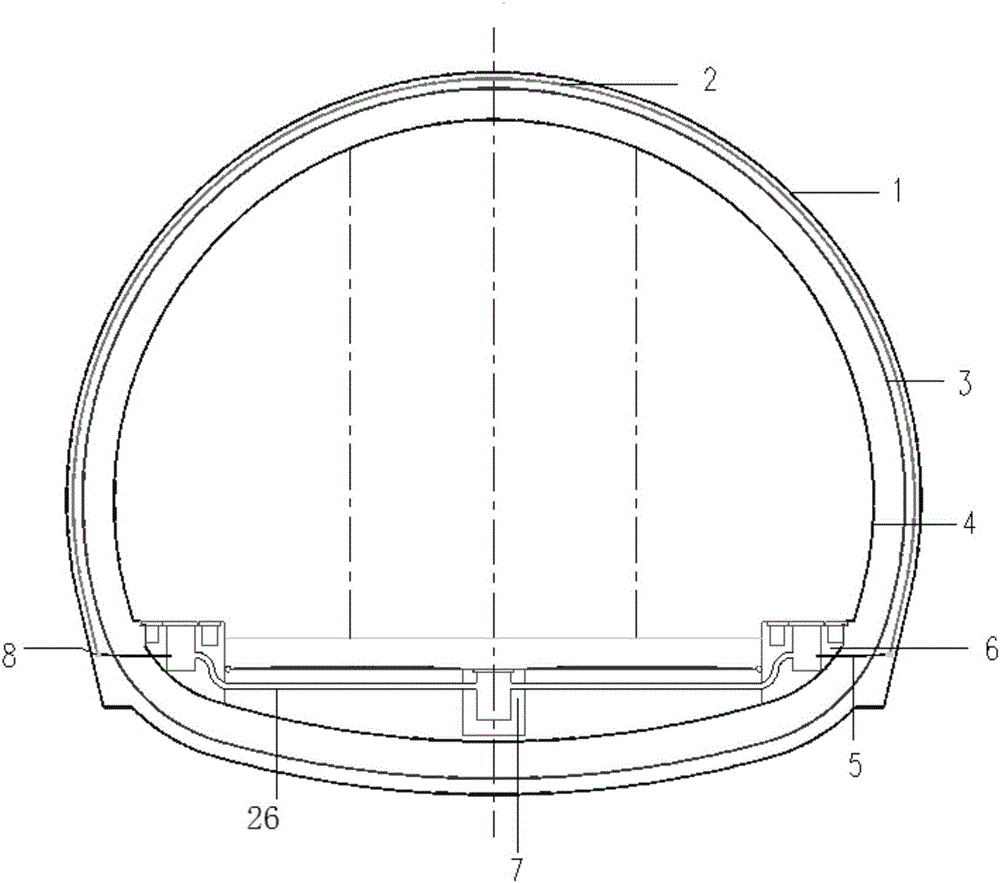

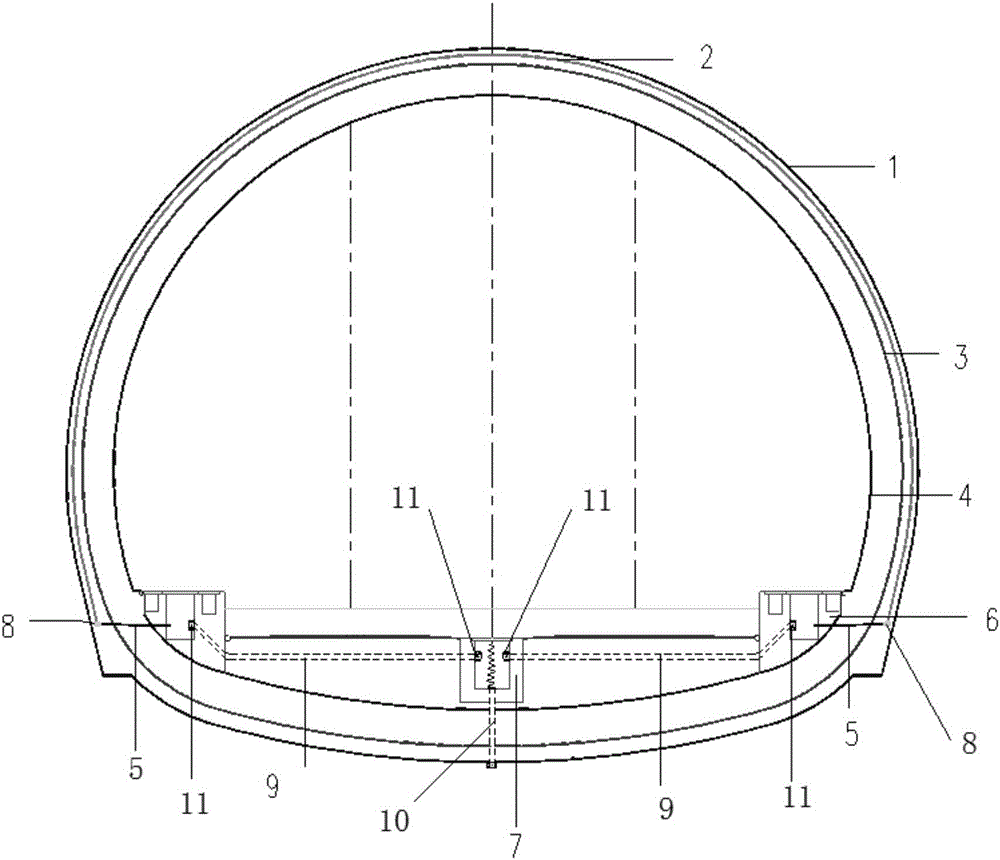

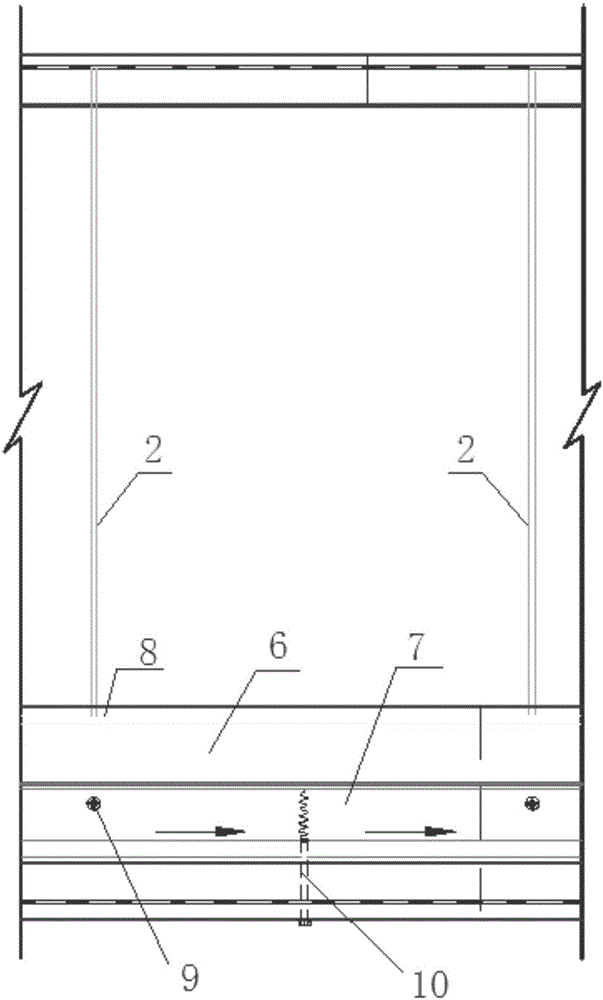

[0042] Such as figure 2 , 3 As shown, in the pressure-bearing tunnel bottom structure drainage system disclosed in the present invention, a central drainage ditch 7 is arranged in the tunnel, and a drainage side ditch 6 is arranged on each side of the tunnel, and pressure-bearing and permeable materials 19 are pre-embedded in the tunnel to form The horizontal drainage channel 9 connecting the central drainage ditch 7 and the drainage side ditch 6 is provided with a plurality of horizontal drainage channels 9 at intervals. In order to facilitate drainage, the lateral slope of the lateral drainage channel 9 is 2%.

[0043]The pressure-bearing water-permeable material 19 is a fabric or a rope, and the fabric is laminated in multiple layers or rolled into bundles t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com