A mobile cable holder

A cable support and mobile technology, applied in electrical components and other directions, can solve problems such as low fault tolerance, hindering the smooth installation of supports, bridges, and load-bearing damage to the upper floor, achieving good reliability, avoiding damage, and improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

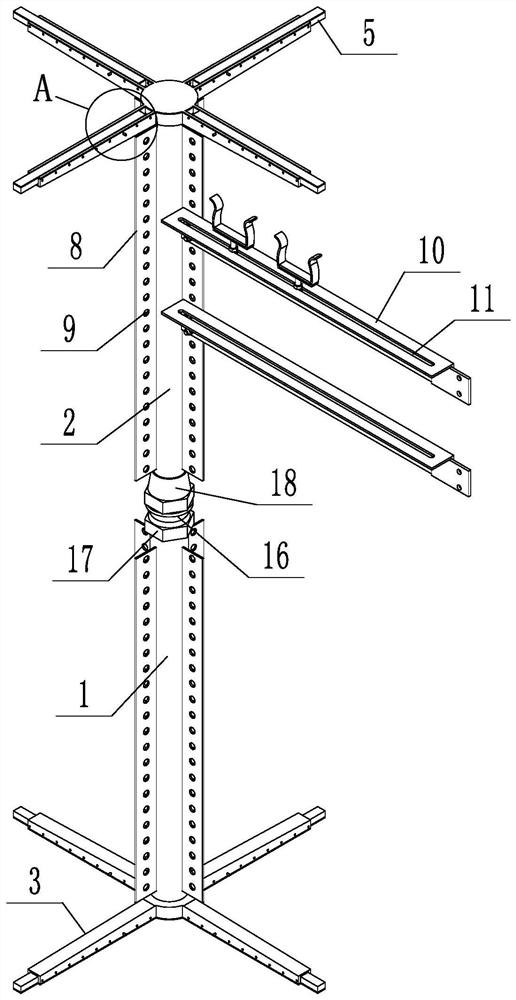

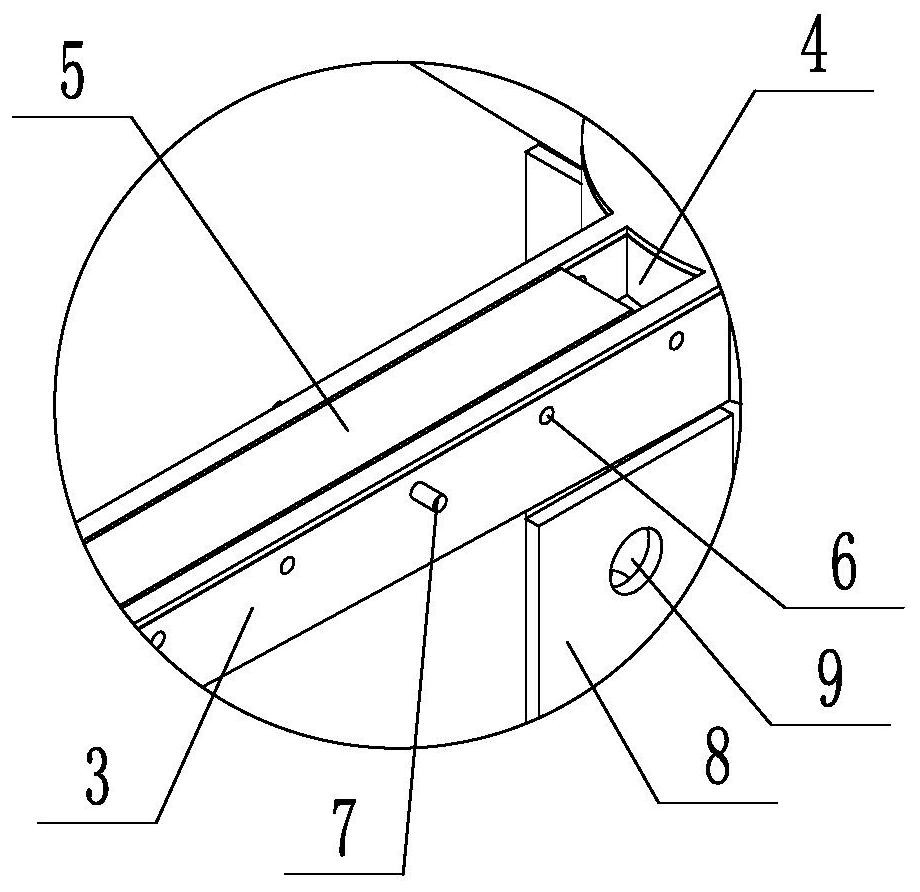

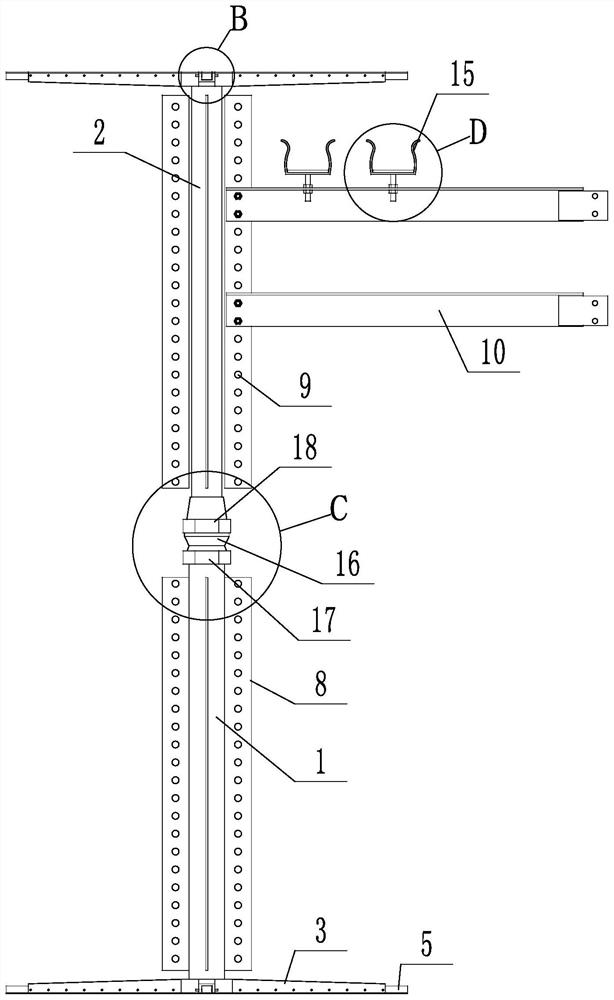

[0035] Such as Figure 1 to Figure 7As shown, a mobile cable support includes a lower support rod 1, an upper support rod 2 and a cross brace 10, the lower end of the upper support rod 2 penetrates into the lower support rod 1 and is slidably connected with the lower support rod 1, and the lower support rod A drive mechanism for driving the upper support rod 2 to move up and down is provided between the rod 1 and the upper support rod 2, the lower end of the lower support rod 1 and the upper end of the upper support rod 2 are provided with a support 3, and the support 3 of the lower support rod 1 Supported on the ground, the upper support rod 2 is driven upward by the driving mechanism, so that the support 3 of the upper support rod 2 is supported on the ceiling, so as to realize the fixation of the bracket, without setting any embedded parts and expansion bolts for fixing, and the installation position can be adjusted Freely set according to the cable path, simple engineering...

Embodiment 2

[0043] Such as Figure 8 As shown, the upper support rod 2 is provided with a first drive rod 24, and the upper support rod 2 is provided with an internal thread. The lower end of the first drive rod 24 is connected to the inner wall of the lower support rod 1 through bearing rotation. The rod 24 is threadedly connected with the inner wall of the upper support rod 2, the side wall of the lower support rod 1 is provided with a drive sleeve 26, and the drive sleeve 26 is provided with a second drive rod 27, and the second drive rod 27 is connected with the drive The sleeves 26 are connected in rotation, the end of the second driving rod 27 is provided with a first bevel gear 28, and the first driving rod 24 is provided with a second bevel gear 29, and the first bevel gear 28 and the second bevel gear 29 mesh. During use, the second driving rod 27 is manually rotated, and the first driving rod 24 is driven to rotate through the engagement of the first bevel gear 28 and the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com