Sewing machine provided with thread guiding frame

A sewing machine and lead frame technology, which is applied to sewing machine components, sewing equipment, bobbin insertion rod components, etc., can solve the problem that the lead frame cannot be smoothly and efficiently realized the threading operation, etc., so as to meet the processing needs of the sewing machine, easy to operate, and smooth threading. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

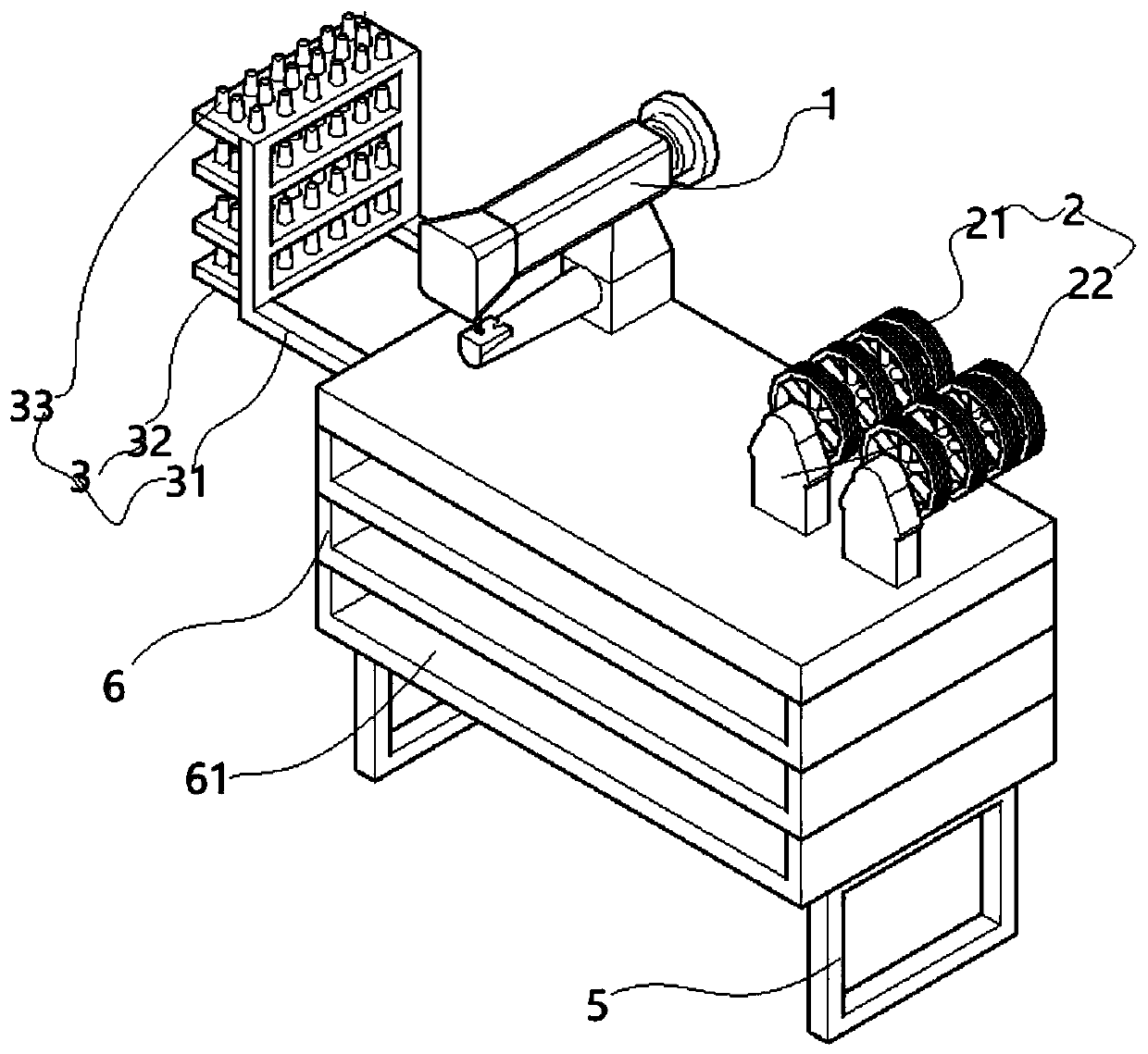

[0044] Such as Figure 1-3 As shown, a sewing machine provided with a lead frame includes a workbench, and the top left side of the workbench is equipped with a sewing machine body 1. Among them, the sewing machine body 1 is a conventional sewing machine disclosed in the prior art, and its main function is to hem clothing.

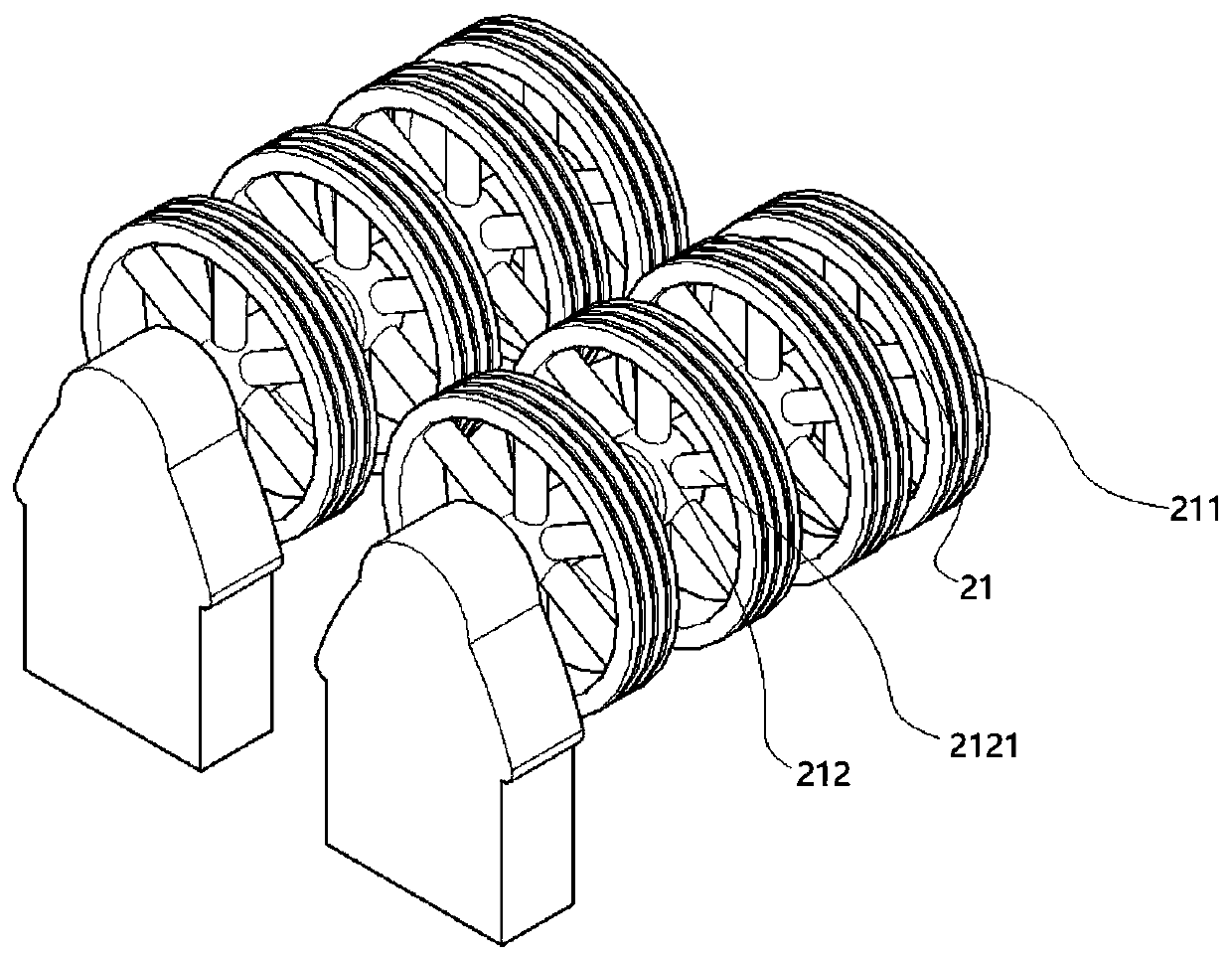

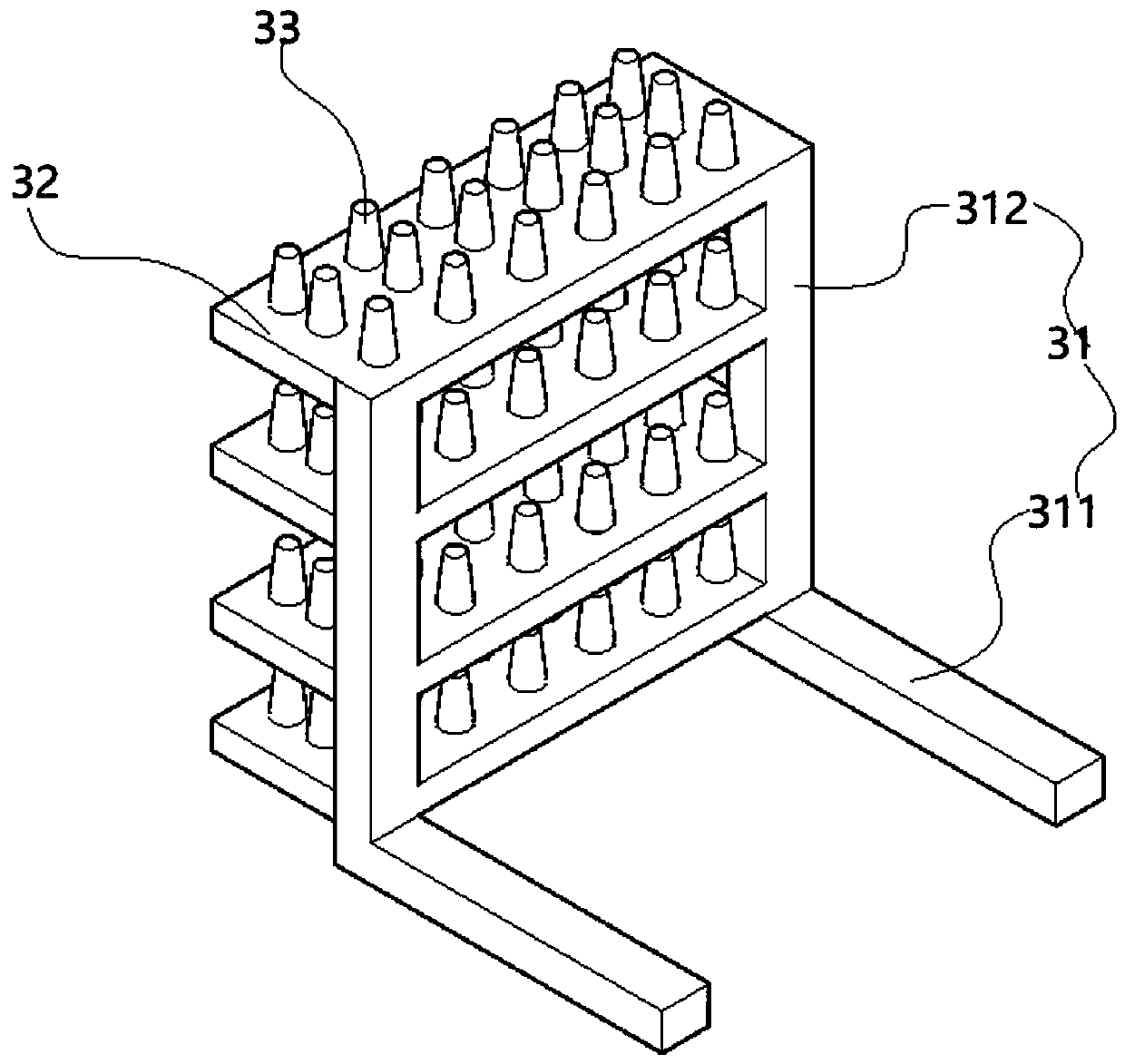

[0045] In order to solve the technical problem that the lead wire of the existing sewing machine body 1 is not smooth enough and the lead wire is cumbersome, the present invention adopts the following design to solve the problem: the sewing machine of the lead frame also includes two left and right pay-off wheel assemblies arranged on the top right side of the workbench. 2. Pay-off is realized through pay-off wheel assembly 2. The pay-off wheel assembly 2 includes a number of pay-off wheels 21 arranged at intervals in the front and back, and each pay-off wheel 21 is provided with a number of pay-off slots 211, and a rotating shaft is rotatably connected betwe...

Embodiment 2

[0052] Such as Figure 1-7 As shown, a sewing machine provided with a lead frame includes a workbench, and the top left side of the workbench is equipped with a sewing machine body 1. The sewing machine of the lead frame also includes two pay-off wheel assemblies 2 arranged at intervals on the left and right, which are assembled on the top right side of the workbench, and the pay-off is realized by the pay-off wheel assembly 2. The pay-off wheel assembly 2 includes a number of pay-off wheels 21 arranged at intervals in the front and back, and each pay-off wheel 21 is provided with a number of pay-off slots 211, and a rotating shaft is rotatably connected between the several pay-off wheels 21 The wheel centers of a number of the pay-off wheels 21 are rotatably connected to the rotating shaft; the rotating shaft is rotatably connected with a seat frame 22 (the seat frame 22 is fixedly connected to the top of the workbench). Specifically, the inner wall of the pay-off wheel 21 is...

Embodiment 3

[0061] Such as Figure 1-7 As shown, a sewing machine provided with a lead frame includes a workbench, and the top left side of the workbench is equipped with a sewing machine body 1. Among them, the sewing machine body 1 is a conventional sewing machine disclosed in the prior art, and its main function is to hem clothing.

[0062] The sewing machine of the lead frame also includes two pay-off wheel assemblies 2 arranged at intervals on the left and right, which are assembled on the top right side of the workbench, and the pay-off is realized by the pay-off wheel assembly 2. The pay-off wheel assembly 2 includes a number of pay-off wheels 21 arranged at intervals in the front and back, and each pay-off wheel 21 is provided with a number of pay-off slots 211, and a rotating shaft is rotatably connected between the several pay-off wheels 21 , The wheel centers of a number of the pay-off wheels 21 are rotatably connected to a rotating shaft; the rotating shaft is rotatably connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com