Straight-through variable flow solenoid control valve

An electromagnetic control valve and variable flow technology, which is applied in valve details, valve devices, valve operation/release devices, etc., can solve the problems of flow control valve reliability, structural quality and volume that cannot meet the design index requirements, flow adjustment, etc. Unable to achieve functions and other problems, to achieve the effect of simple structure, simple control method, small mass and volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

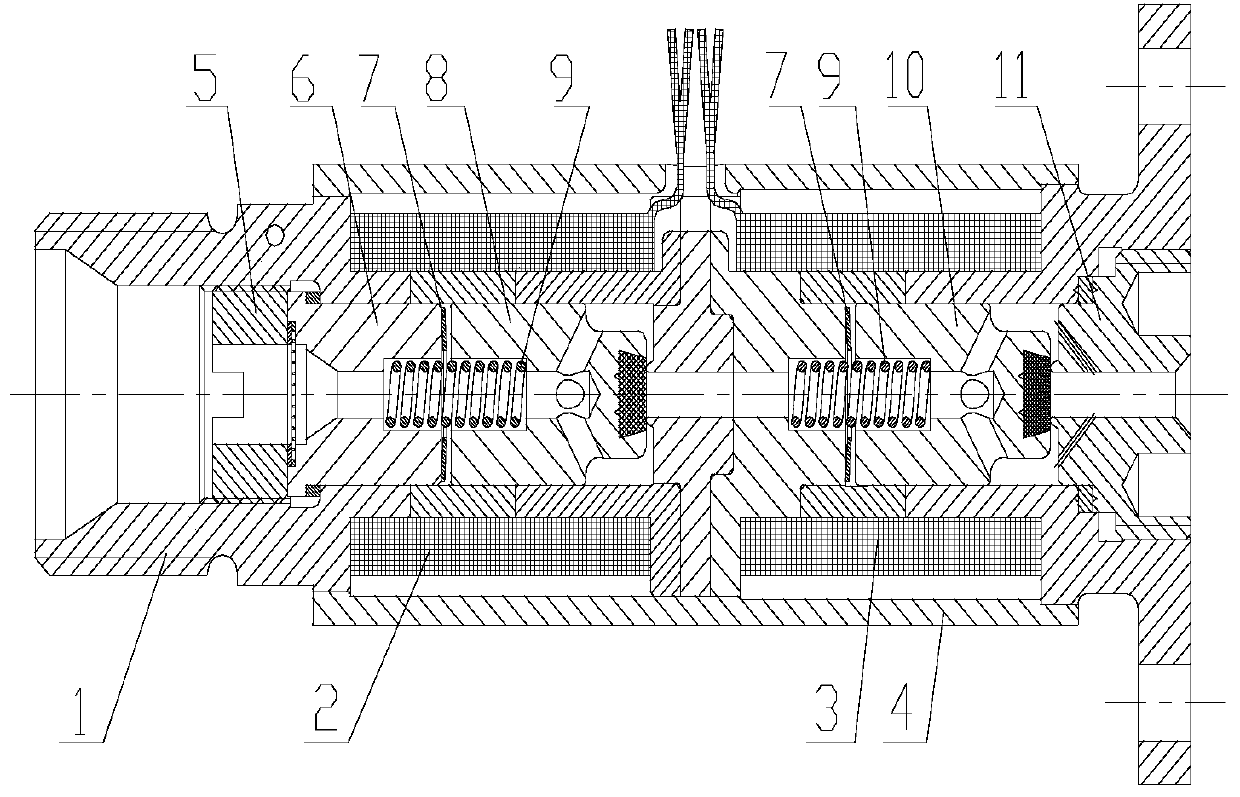

[0027] figure 1 Shown is the axial sectional view of the internal structure of the present invention, that is, the basic structural form of the present invention, which consists of a main valve body 1, a left coil 2, and a right coil 3 (the coil adopts electromagnetic wires with good conductivity to be wound and dipped in paint and dried made), left spool 8, right spool 10, filter 5, stop iron 6, spring 9, disc spring 7, right valve seat 11 and outer shell 4, two coils are wound on the main valve body, The shell is fitted on the main valve body through interference fit, forming a closed-loop magnetic circuit together with the main valve body and the valve core. The filter 5 and the right valve seat 11 are assembled with the main valve body 1 through threads.

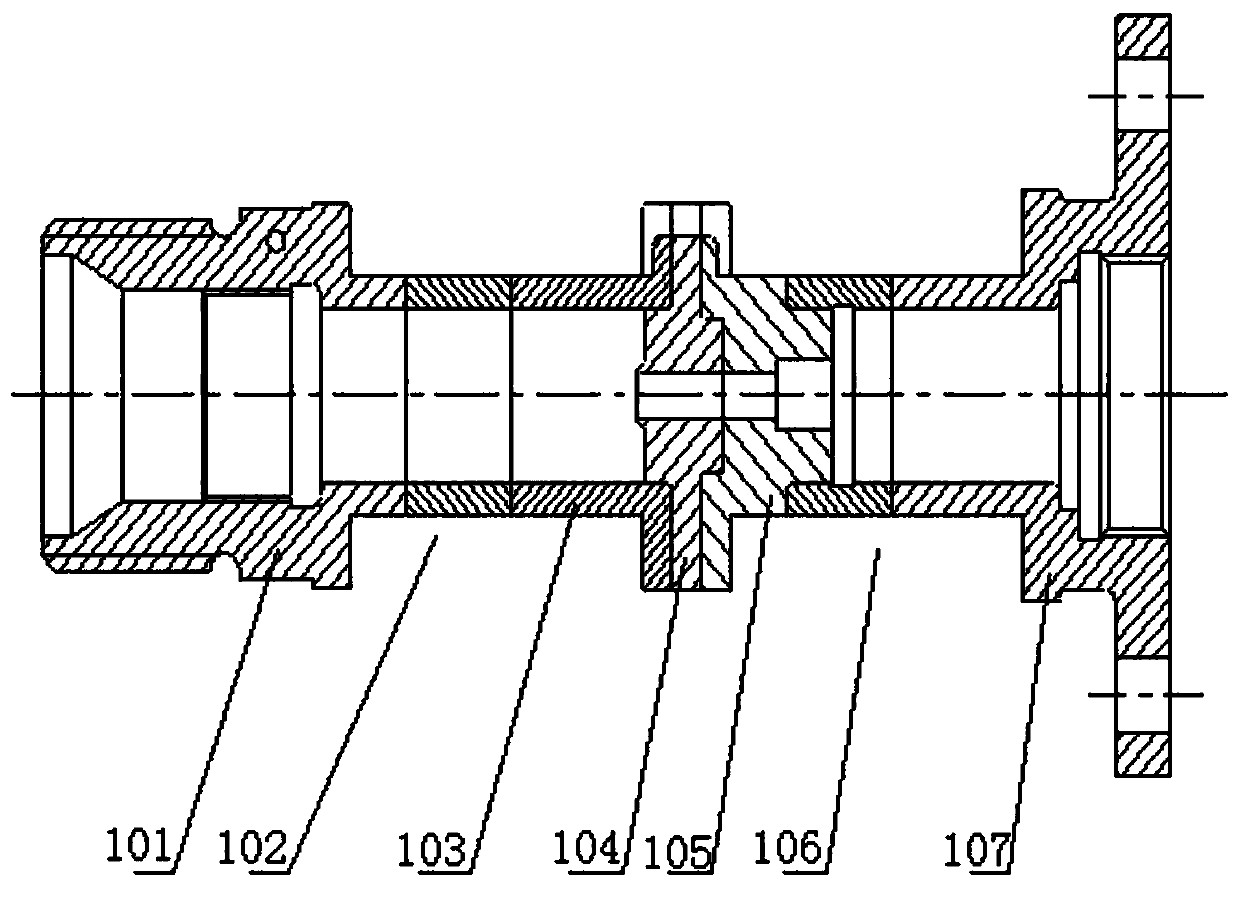

[0028] figure 2 Shown is the axial section view of the structure of the main valve body of the present invention, the main valve body consists of a terminal 101, a left magnetic isolation ring 102, a sleeve 103, a left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com