A direct-acting electro-hydraulic proportional valve driven by a bidirectional permanent magnet linear force motor

An electro-hydraulic proportional valve, motor-driven technology, applied in valve details, valve devices, engine components, etc., can solve problems such as poor specific force characteristics, achieve high power/weight ratio, compact structure, and improve linearity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is specifically described below by the embodiment, only for further illustrating the present invention, can not be interpreted as the limitation of protection scope of the present invention, the technical engineer of this field can make some non-essential improvements and improvements to the present invention according to the content of the above-mentioned invention Adjustment.

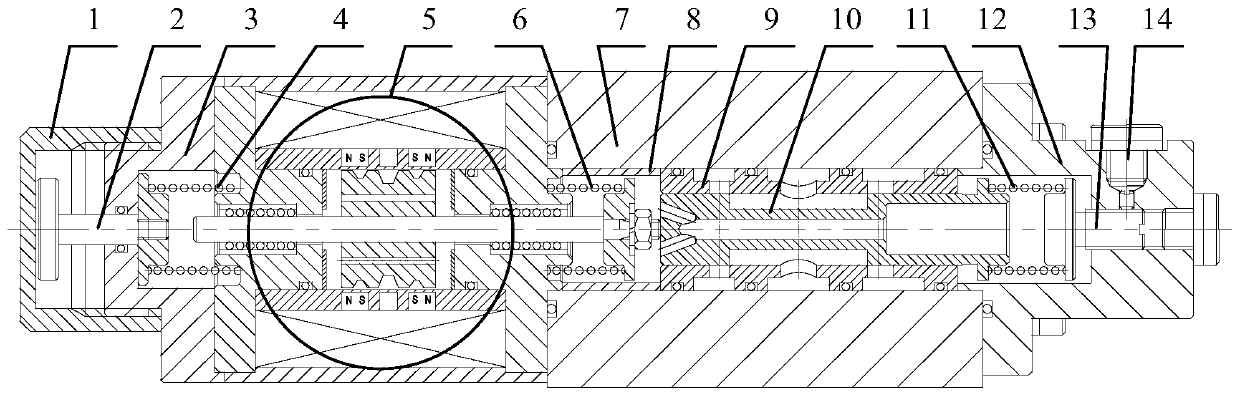

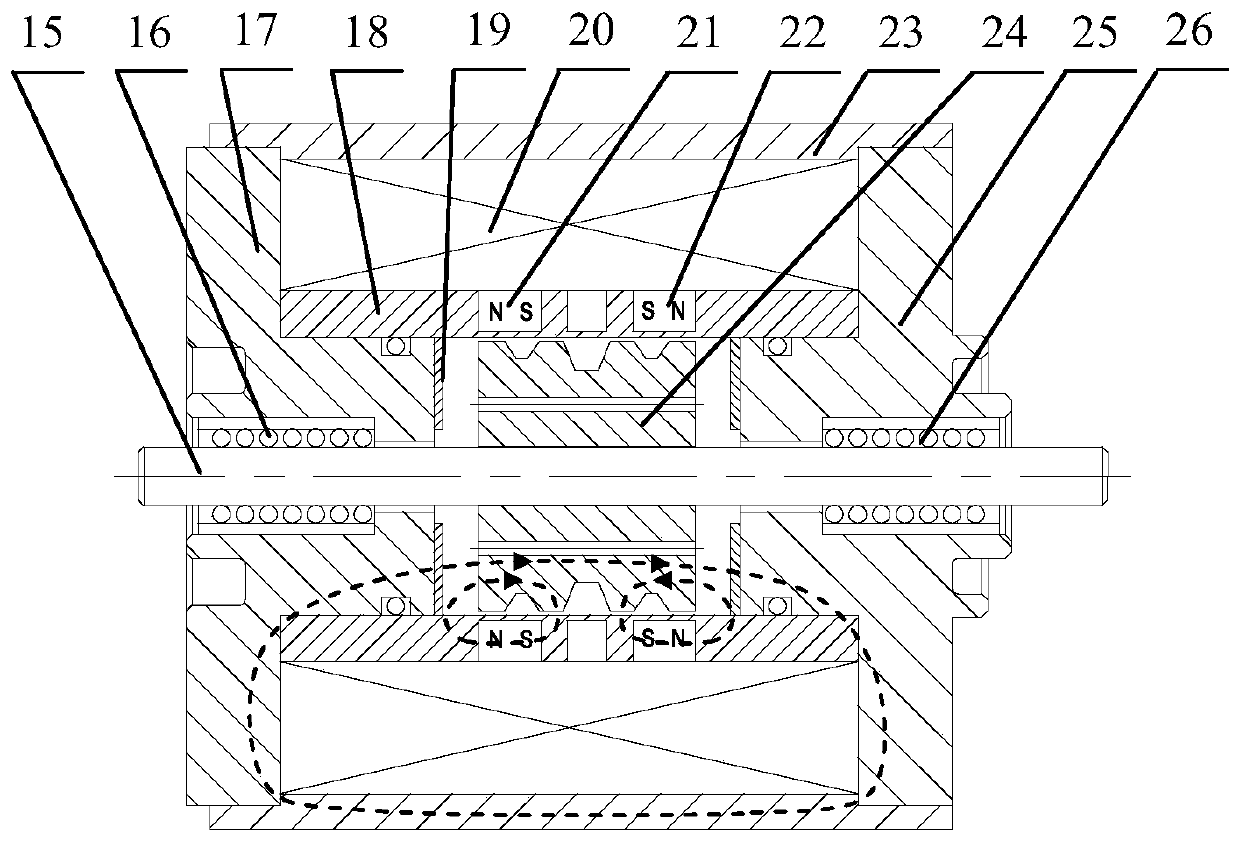

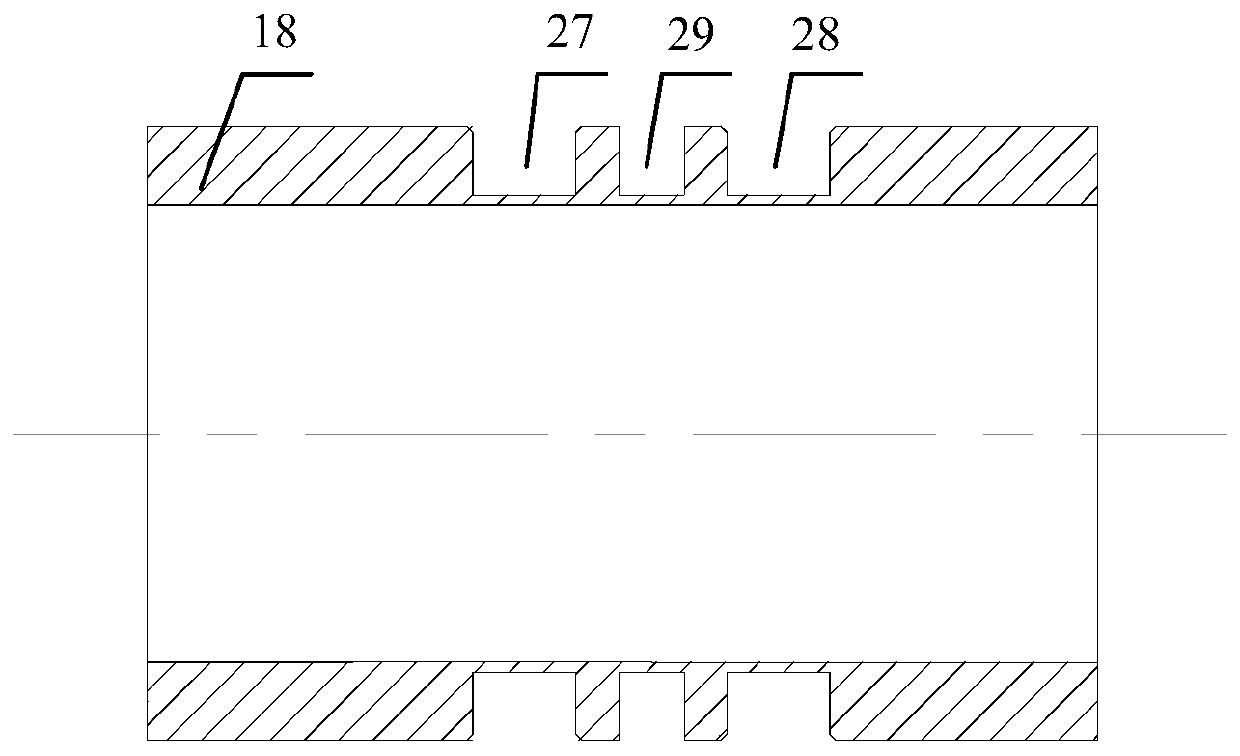

[0026] like figure 1 As shown, the present invention includes a left end cover 1, a manual return lever 2, a left yoke 3, a return spring 4, a bidirectional permanent magnet linear force motor 5, a centering spring A6, a valve body 7, a sleeve 8, a valve sleeve 9, and a valve Core 10, centering spring B11, right end cover 12, adjusting screw 13, set screw 14; one side of the two-way permanent magnet linear force motor is directly connected with the valve core 10 through the push rod 15, and the other side is connected with the valve core 10 by the left end cover 1, manual ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com