Tilting type pure-oxygen fuel gas rotary furnace

A rotary furnace and gas technology, applied in the furnace, furnace cooling, burner and other directions, can solve the problems of the gas rotary furnace not being tilted, hidden dangers, inconvenient use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

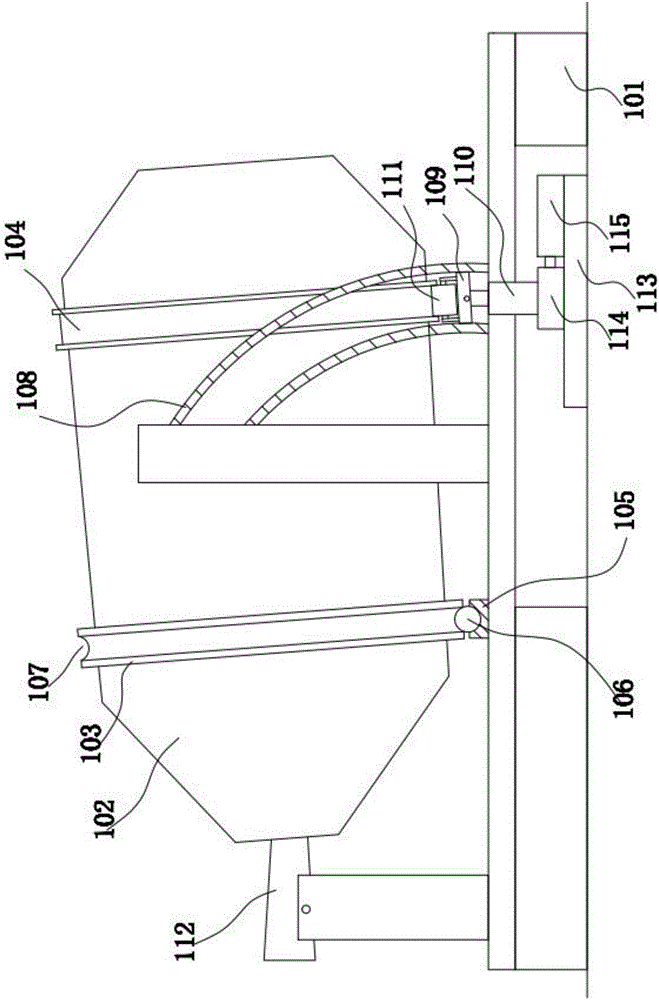

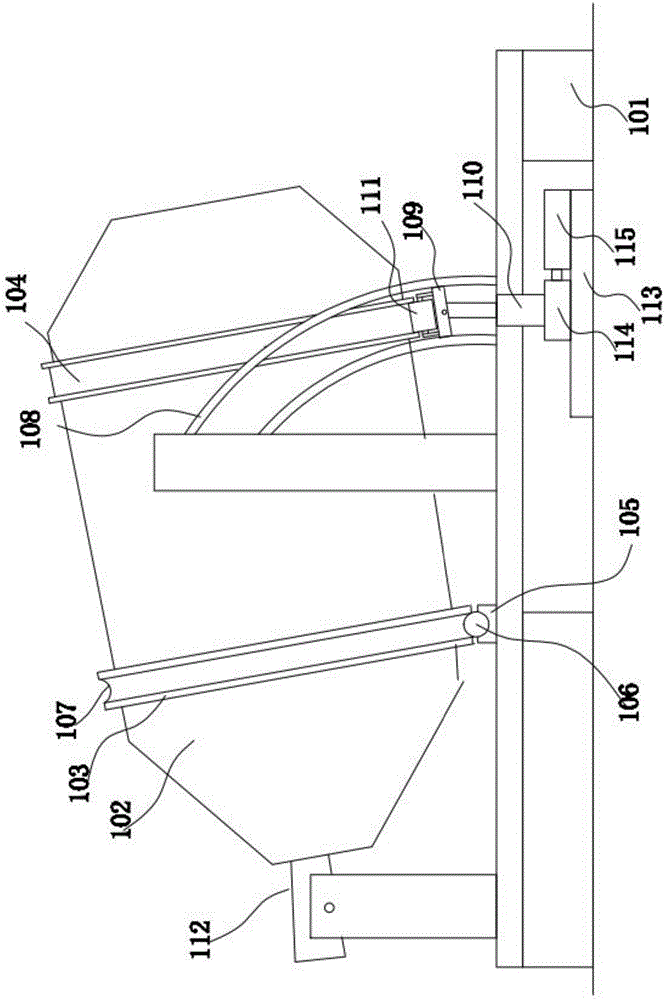

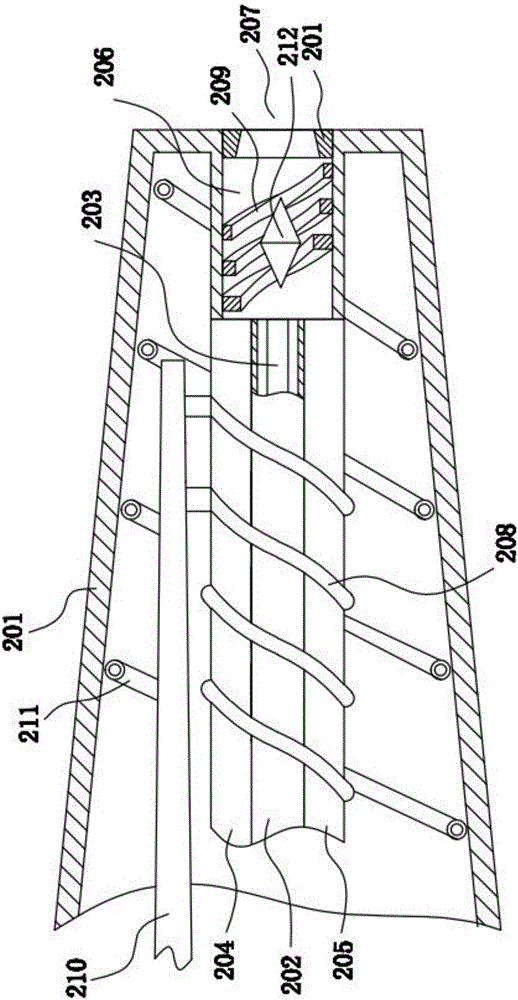

[0024] Such as figure 1 and figure 2 As shown, a tiltable pure oxygen gas-fired rotary furnace includes a frame 101 and a furnace body 102. The front part of the furnace body 102 is provided with a first guide ring 103, and the rear part of the furnace body is covered with a The second guide ring 104, the frame 101 is provided with the idler seat 105 below the first guide ring 103 and the support ball 106 supported on the first guide ring 103, the bottom of the support ball 106 is rotatably mounted on On the idler seat 105, the first guide ring 103 is provided with an arc surface 107 matched with the top of the support ball 106, and the frame is provided with an arc guide rail 108, and the arc guide rail A support base 109 is movably installed in 108, and a lifting device is provided between the support base 109 and the frame 101. The lifting device includes a hydraulic cylinder 110, and the piston rod of the hydraulic cylinder 110 is hinged on the support base. 109, the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com