Range hood serially connected with double fans

A range hood and dual fan technology, applied in the field of range hoods, can solve the problems of weak resistance to back pressure and easy backflow, and achieve the effect of improving the smoking ability and strong suction and gathering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

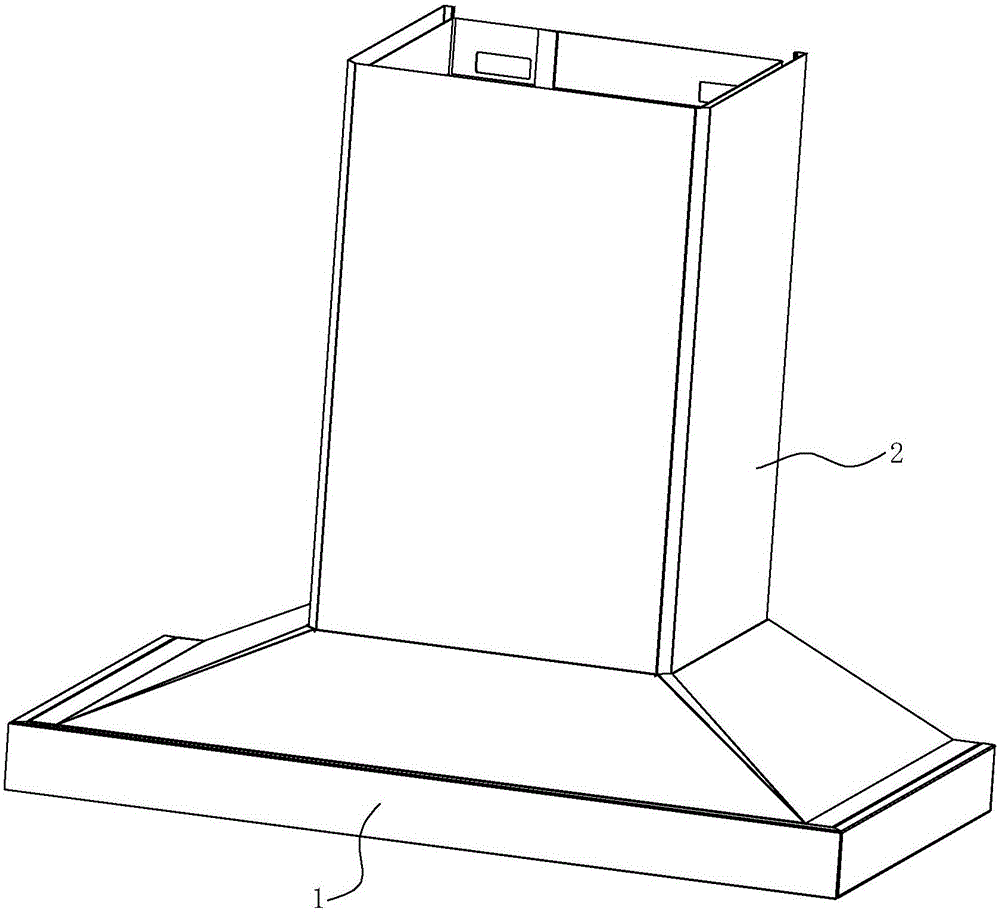

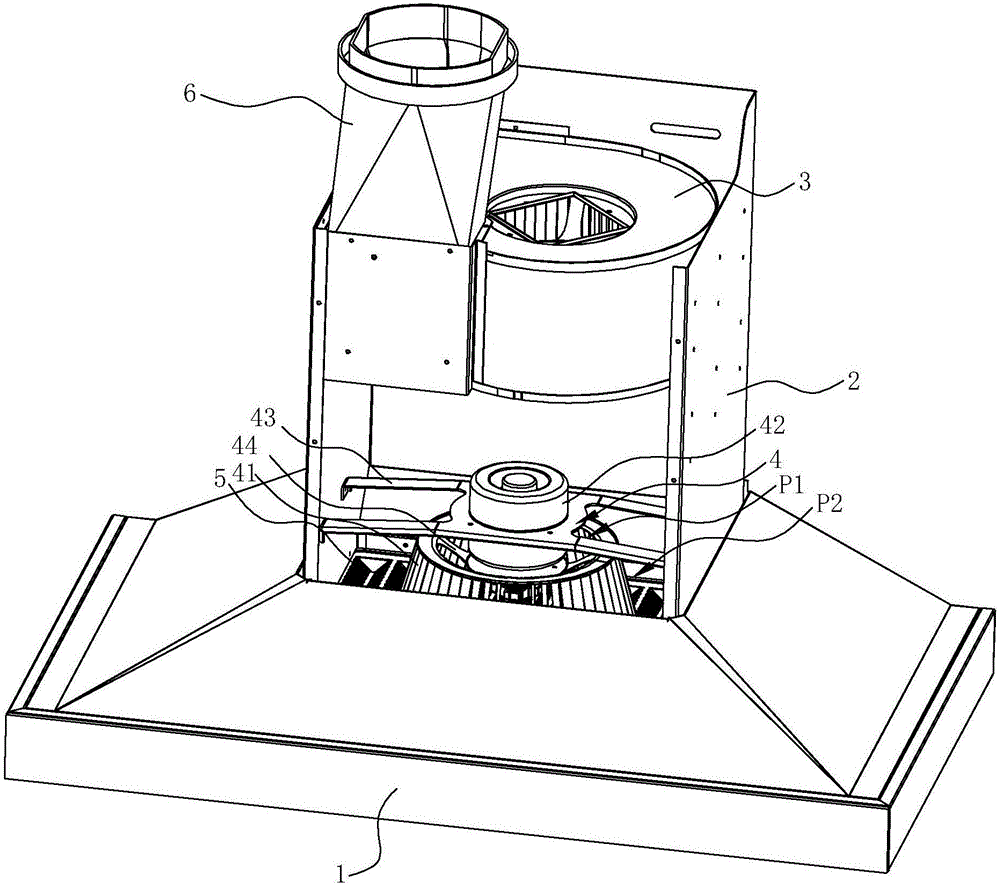

[0020] see Figure 1 ~ Figure 3 , a range hood with two fans connected in series, comprising a smoke collecting hood 1, a fan cover 2, a first fan 3 and a second fan 4. The smoke collecting hood 1 is provided with an air inlet, the air inlet is provided with a filter screen 5, the first fan 3 is arranged in the fan cover 2, the second fan 4 is arranged above the filter screen 5 and is located in the fan cover 2, the first The fan 3 is located above the second fan 4 . Through the method of connecting the first fan 3 and the second fan 4 in series, the deficiency of the horizontal fan is made up and the advantages of the horizontal fan are strengthened. An air outlet hood 6 is arranged at the air outlet of the first blower 3 for exhausting oily fume from the range hood.

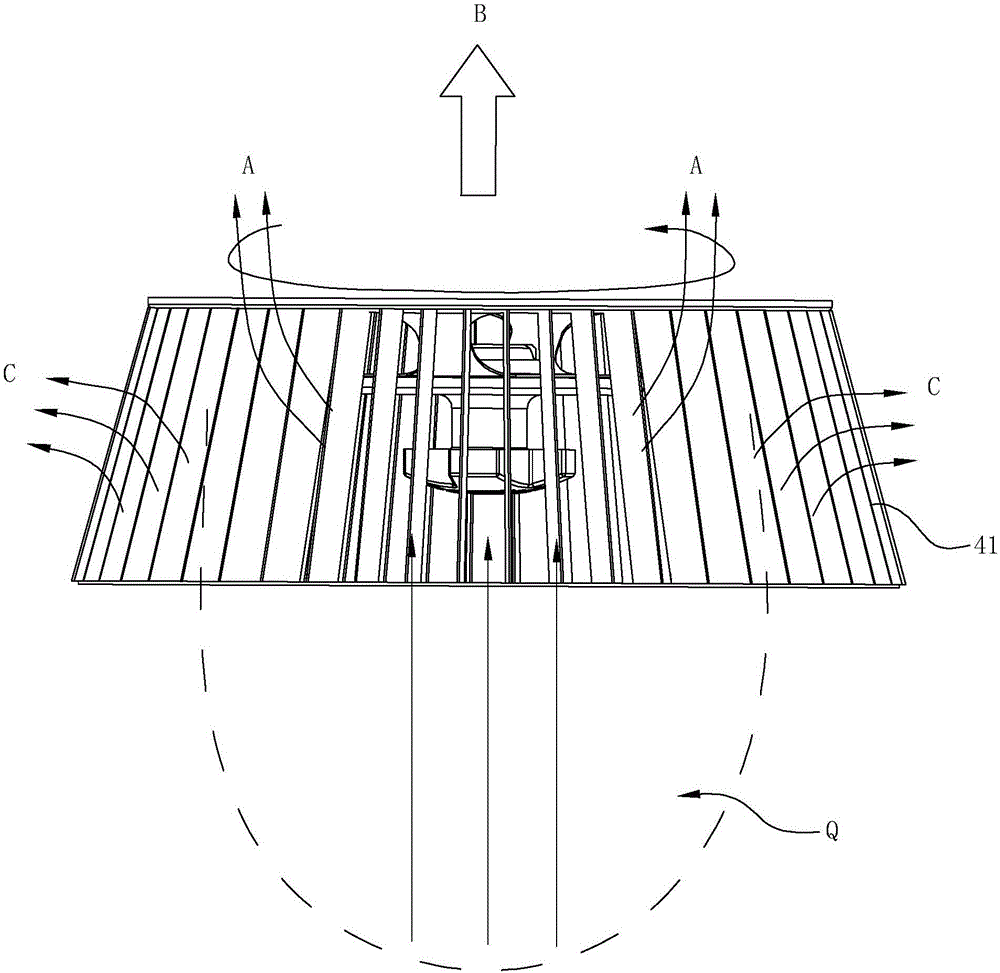

[0021] The first fan 3 is a centrifugal fan, which can adopt the existing structure. The second fan 4 is a centrifugal fan without a volute, including a conical impeller 41 and a motor 42 that drives the coni...

Embodiment 2

[0026] see Figure 4 , In this embodiment, the difference from Embodiment 1 is that the first blower fan 3 is inclined, that is, it is inclined relative to the vertical direction. The angle of the first fan 3 relative to the vertical direction is 0°˜90°.

Embodiment 3

[0028] see Figure 5 and Figure 6 , In this embodiment, the difference from Embodiment 1 is that a flow guide member 45 is arranged inside the conical impeller 41, and the flow guide member 45 is in the shape of a cone with a small bottom and a large top. Because the motor 42 will cause a certain air flow blockage, which will have a certain impact on the air volume of the first middle channel P1 and also increase the noise. Therefore, the air guide member 45 is provided to reduce the impact to a certain extent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com