Middle-deep ground temperature compound mode buried pipe heat exchange device

A composite mode, heat exchange tube technology, applied in heating devices, geothermal energy, geothermal power generation, etc., can solve the problems of groundwater source threat, low heat exchange efficiency, high operating energy consumption, and achieve good heat exchange effect and investment cost. Low, the effect of improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

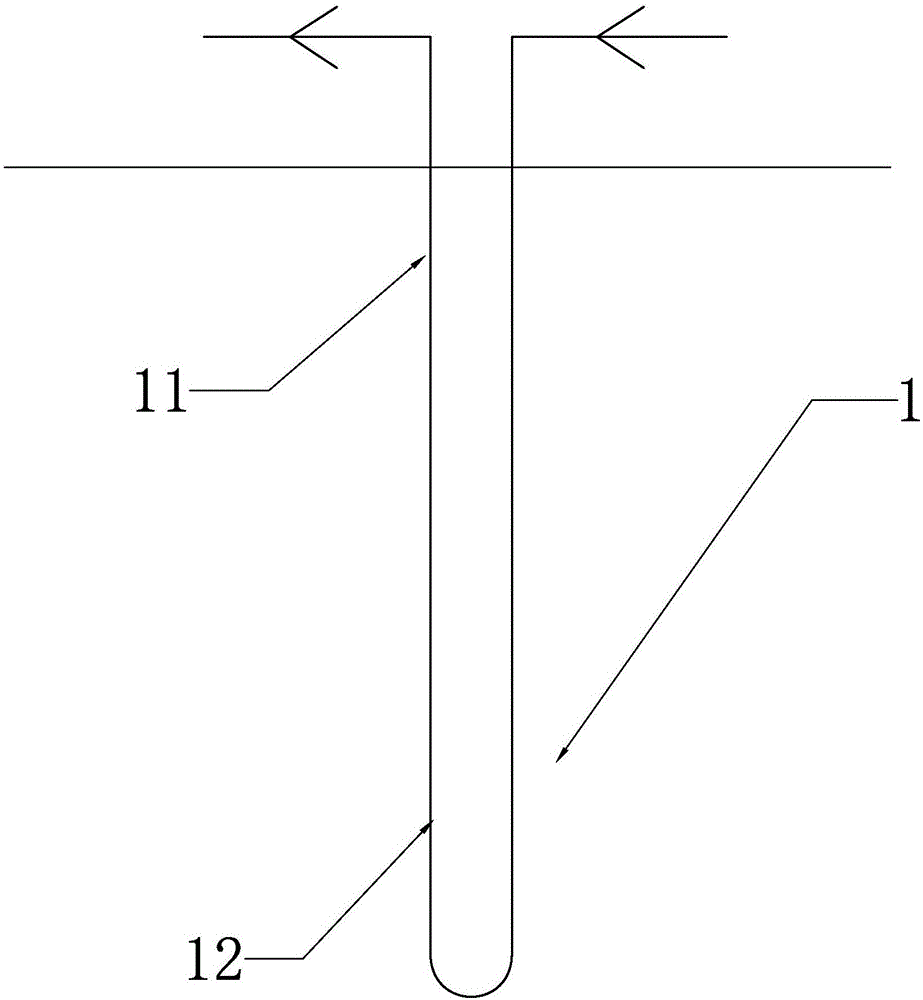

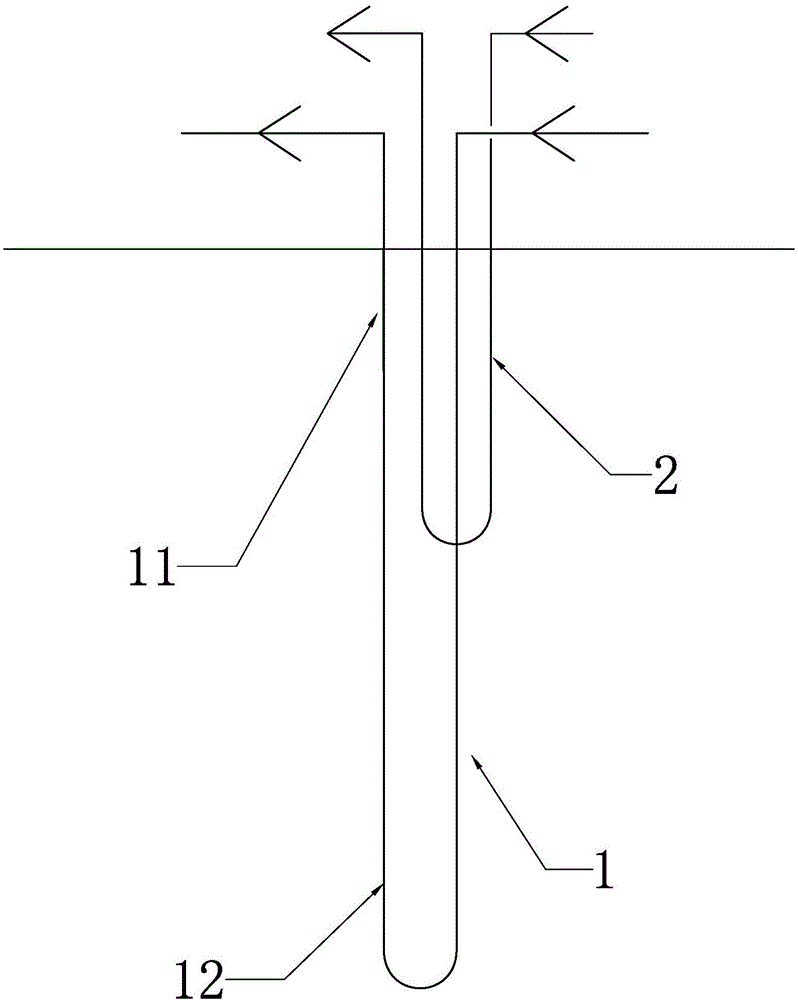

[0022] like figure 1 and figure 2 As shown, the medium-deep ground temperature compound mode heat exchange buried pipe device of the present invention includes a deep buried heat exchange pipe 1 buried in the underground soil, and the deep buried heat exchange pipe 1 is filled with a first heat exchange working medium and The two ends of the deep buried heat exchange tube 1 are connected to the user side, and at least one middle buried heat exchange tube buried in the underground soil and filled with the second heat exchange working medium is arranged on the upper end side of the deep buried heat exchange tube 1 2. Both ends of the middle buried heat exchange tube 2 are respectively connected to the user side, and the deep buried heat exchange tube 1 is divided into a heat preservation area 11 and a heat exchange area 12 from top to bottom, and all of the middle buried heat exchange tubes 2 or Locally located in the thermal insulation area 11, this embodiment uses the compou...

Embodiment 2

[0028]This embodiment is similar to Embodiment 1, except that the deep buried heat exchange tube 1 is located on the outer side of the tube wall of the heat preservation area 11 without an insulation layer, and the deep buried heat exchange tube 1 is located in the part of the heat preservation area 11 Exchange heat with the middle buried heat exchange tube 2; in this case, the deep buried heat exchange tube 1 diffuses the heat in the heat exchange area to the heat preservation area 11, so that the heat in the heat preservation area 11 is greatly increased, and one or more The heat exchange tube 2 buried in the middle layer collects the heat in the heat preservation area to enhance the heat exchange effect and heating effect of the buried heat exchange tube 2 in the middle layer. Multiple buried heat exchange tubes 2 in the middle layer can efficiently transfer heat to multiple different users One deep buried heat exchange tube 1 combines with the middle buried heat exchange tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com