High-supported formwork deformation monitoring and early warning method

A technology of monitoring and early warning, high-support mode, applied in the direction of measuring devices, instruments, etc., can solve problems such as line of sight occlusion, low sampling frequency, long investment time of monitoring personnel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

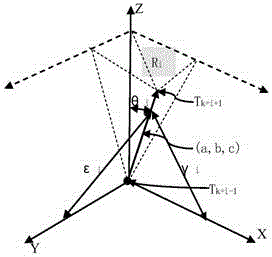

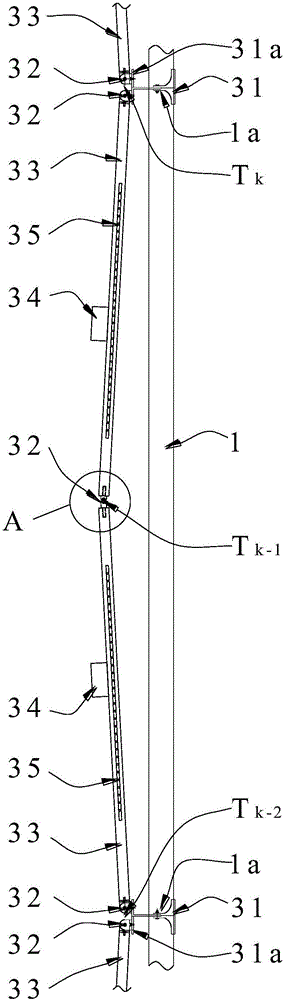

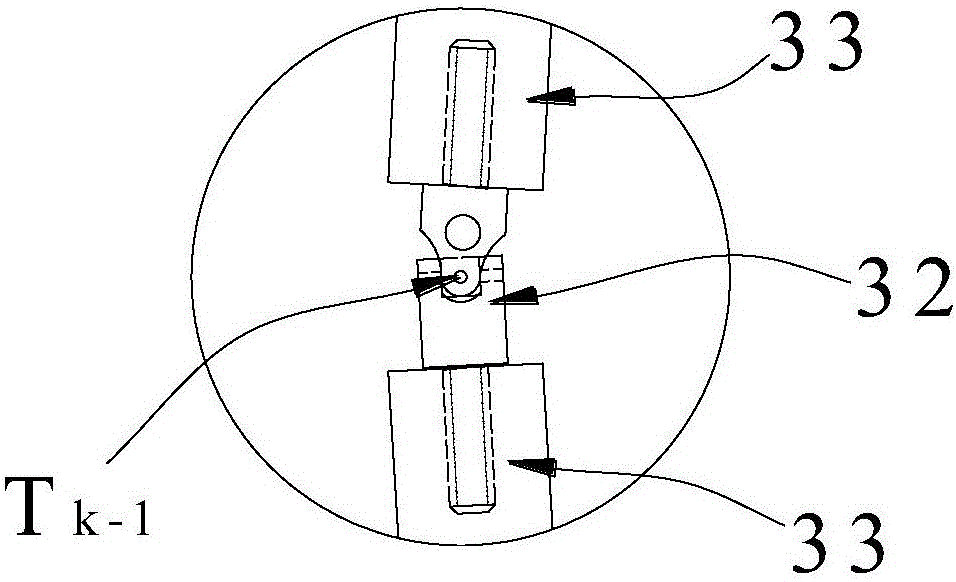

[0050] Such as Figure 1 to Figure 3 As shown, in the high-support formwork deformation monitoring and early warning method of the present invention, the components of the high-support formwork used include a plurality of vertically arranged vertical bars 1 and a plurality of horizontally arranged horizontal bars 2, and the vertical bars 1 and The connection position of the cross bar 2 is called the node 1a of the vertical bar 1 .

[0051] The deformation monitoring and early warning method of the high-end formwork of the present invention comprises: according to the design drawing of the high-end formwork, at least one vertical pole 1 is selected as the deformation monitoring object of the high-end formwork, and the deformation monitoring object is deformed by the deformation monitoring and early warning equipment of the high-end formwork monitor.

[0052] The above-mentioned high-support mold deformation monitoring and early warning equipment is provided with a set of defor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com