Mold state monitoring method and device, industrial personal computer, storage medium and system

A mold and state technology, applied in manufacturing computing systems, computer parts, character and pattern recognition, etc., can solve the problems of detection speed and detection accuracy, achieve real-time performance and accuracy, improve mold monitoring quality and The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

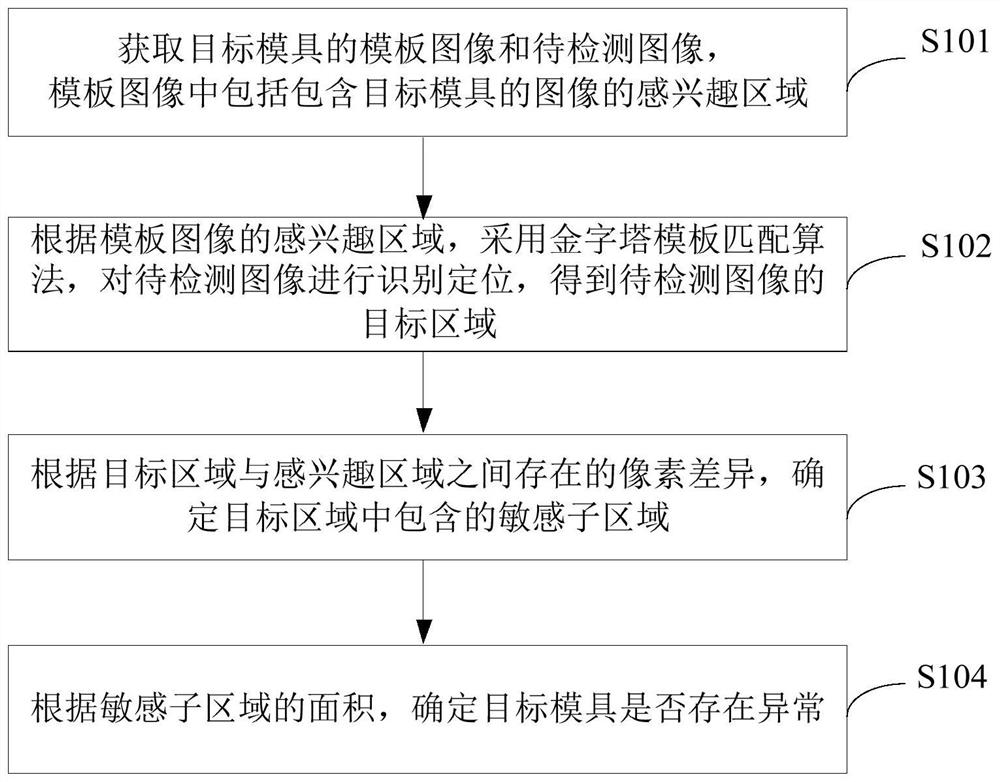

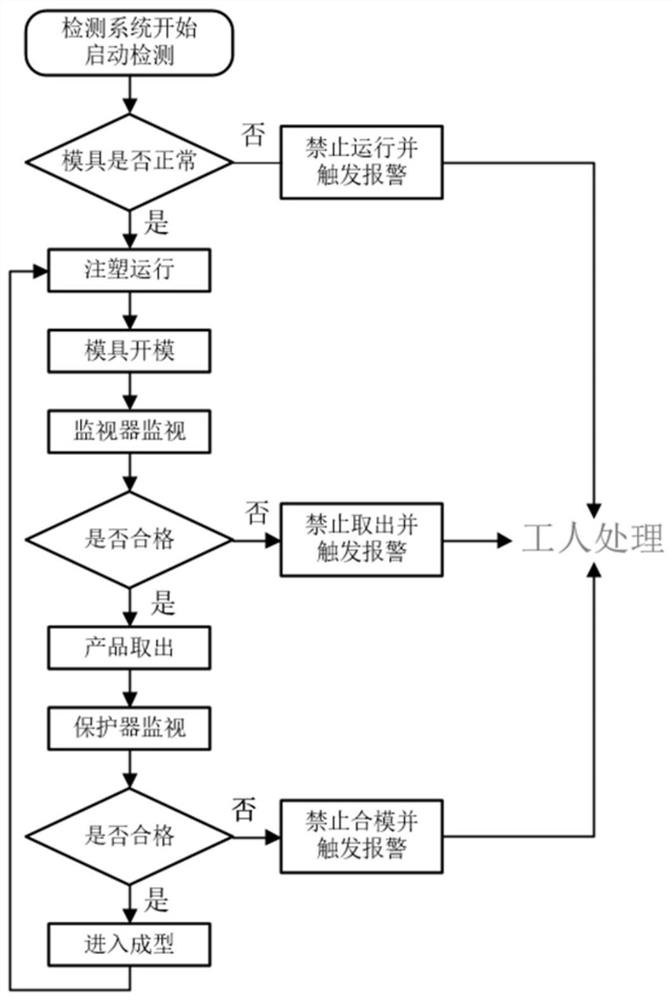

[0055] Illustratively, figure 1A schematic flowchart of the state monitoring method of the mold provided in the first embodiment of the present application. The method of this embodiment can be executed by the state monitoring device of the mold provided by the embodiment of the present application, and the device can be implemented by software and / or hardware. , and can be integrated into the industrial computer. like figure 1 As shown, the state monitoring method of the mold of this embodiment includes:

[0056] S101. Acquire a template image of a target mold and an image to be detected.

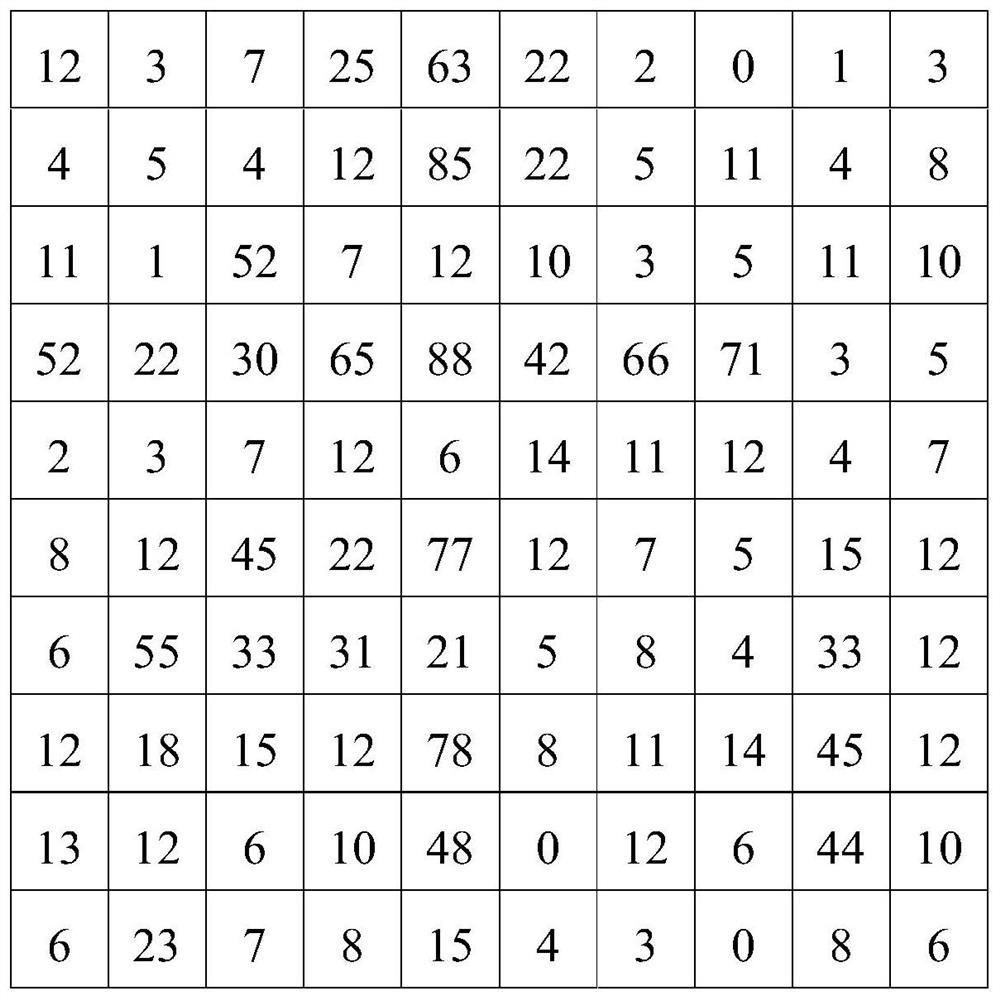

[0057] In this step, when it is necessary to perform state detection on the target mold, the template image and the image to be detected of the same target mold collected by the visual imaging component are obtained, wherein the template image is the image of the target mold in a normal state, that is, when the visual imaging component is used When the quality of the target mold is inta...

Embodiment 2

[0082] The preprocessing process of the template image of the target mold will be described below through a specific embodiment, for example, Image 6 A schematic flowchart of the preprocessing process of the template image provided in the second embodiment of the present application, such as Image 6 As shown, in this embodiment, the preprocessing of the template image includes:

[0083] S201: Determine a pre-selected area of the template image according to a frame selection operation performed by a user on the target mold in the template image on the human-computer interaction interface.

[0084] The industrial computer provided by this embodiment includes a human-computer interaction interface, and the user can view the image collected by the visual imaging component through the human-computer interaction interface, and perform corresponding operations on the image. In a possible implementation manner, in this embodiment, the region of interest of the template image is d...

Embodiment 3

[0097] Figure 7 A schematic structural diagram of the state monitoring device for a mold provided in Embodiment 3 of the present application, as shown in Figure 7 As shown, the state monitoring device 10 of the mold in this embodiment includes:

[0098] Image acquisition module 11 and image processing module 12 .

[0099] The image acquisition module 11 is used to acquire the template image and the image to be detected of the target mold; the template image is the image of the target mold in a normal state, and the template image includes an image of interest including the image of the target mold area;

[0100] The image processing module 12 is configured to identify and locate the image to be detected by using a pyramid template matching algorithm according to the region of interest of the template image to obtain the target area of the image to be detected; According to the pixel difference existing between the regions of interest, the sensitive sub-region included i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com