a force measuring device

A force measuring device and testing shaft technology, applied in measuring devices, force/torque/work measuring instruments, instruments, etc., can solve problems such as lack of effective testing ability for mechanical properties, and achieve simple structure, reduced impact, and high measurement accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

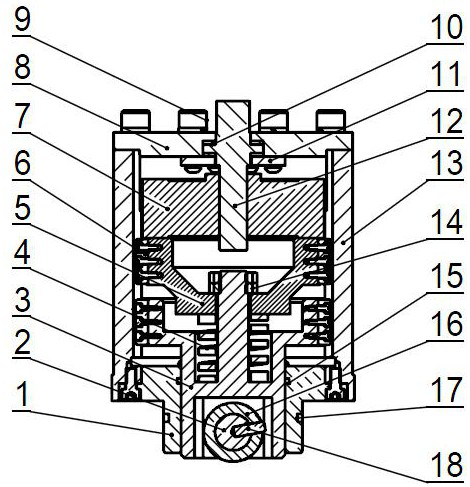

[0022] as attached figure 1 As shown, the force measuring device includes a guide sleeve 1 , a test shaft 3 , a mounting plate 5 , a sensor 7 , a cover 8 and a bracket 13 . The sensor 7 is connected to the test shaft 3 through the mounting plate 5; the test shaft 3 is installed in the guide sleeve 1, and one end of the guide sleeve 1 and the bracket 13 is fixedly connected by a bolt; The contact part of the cover 8 and the adjustment rod 12 is equipped with a bearing 10. The bearing 10 and the adjustment rod 12 are fixedly installed on the cover 8 through the small cover plate 11. The adjustment rod 12 passes through the sensor 7 and forms a spiral fit with the sensor 7. Rotating the adjusting rod 12 can push the sensor 7 to move. A wheel shaft 2 is installed on the test shaft 3 , and a test pressure head 16 is fixedly mounted on the wheel shaft 2 through a pin 18 . Guide rails 6 are fixedly installed on the outer surfaces of the mounting plate 5 and the test shaft 3 respect...

Embodiment example 2

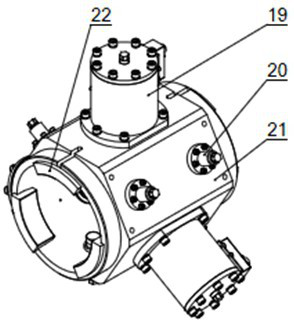

[0026] Refer to attached figure 2 , On the basis of Embodiment 1, the entire force measuring device 19 is fixedly installed on the base 21 . A fastening device 20 and a spacer 22 are installed on the base 21 .

[0027] In Example 1, different mounting bases can be selected for the force measuring device 19. During the design process, a suitable mounting base can be designed according to the shape of the component to be tested to match the moving component to ensure the accuracy of the testing process. The fastening method of the moving component can be selected according to the shape and structure of the component to be tested. The preferred fastening device can be clamped by the top screw, and the number can be selected as one or more according to the needs; at the same time, it can also be designed according to the needs Pads to ensure good contact between irregularly shaped components and the base, eliminating measurement errors caused by poor contact during the test.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com