Low-confining-pressure static and dynamic triaxial testing system based on MTS power source

A triaxial test, power source technology, applied in the application of repetitive force/pulse force to test the strength of materials, the use of stable tension/pressure to test the strength of materials, measurement devices, etc., can solve the problem of large confining pressure difference and force measurement. Large error, unstable low confining pressure environment, etc., to achieve the effect of high confining pressure control accuracy and reducing measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

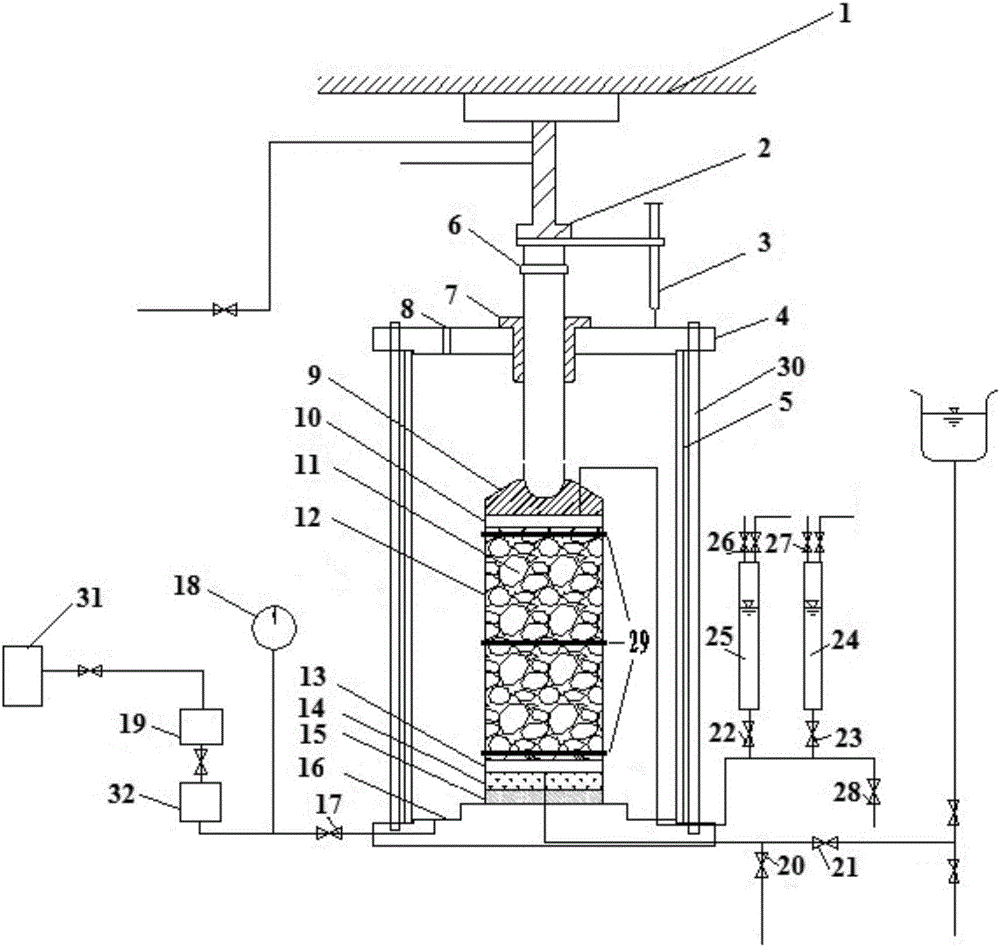

[0030] see figure 1, the low confining pressure static and dynamic triaxial test system based on the MTS power source of the present embodiment includes an MTS testing machine and a triaxial test device, the triaxial test device includes a pressure chamber, a measurement system and a confining pressure control system, and the pressure chamber includes Base 16, side wall 5 and top plate 4, measurement system includes electronic displacement meter 3, radial deformation sensor 29 and force sensor 15, side wall 5 is connected with base 16, top plate 4 sealingly, force sensor 15 is installed on the base 16, force The sample 11 is placed on the sensor 15, and three radial deformation sensors 29 are inserted in the sample 11, and the radial deformation sensors 29...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com