An adaptive movable conductive connection mechanism

A conductive connection and adaptive technology, applied in the direction of electrical components, contact engagement, etc., to achieve the effect of reducing conductive contact area, reducing contact resistance, and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

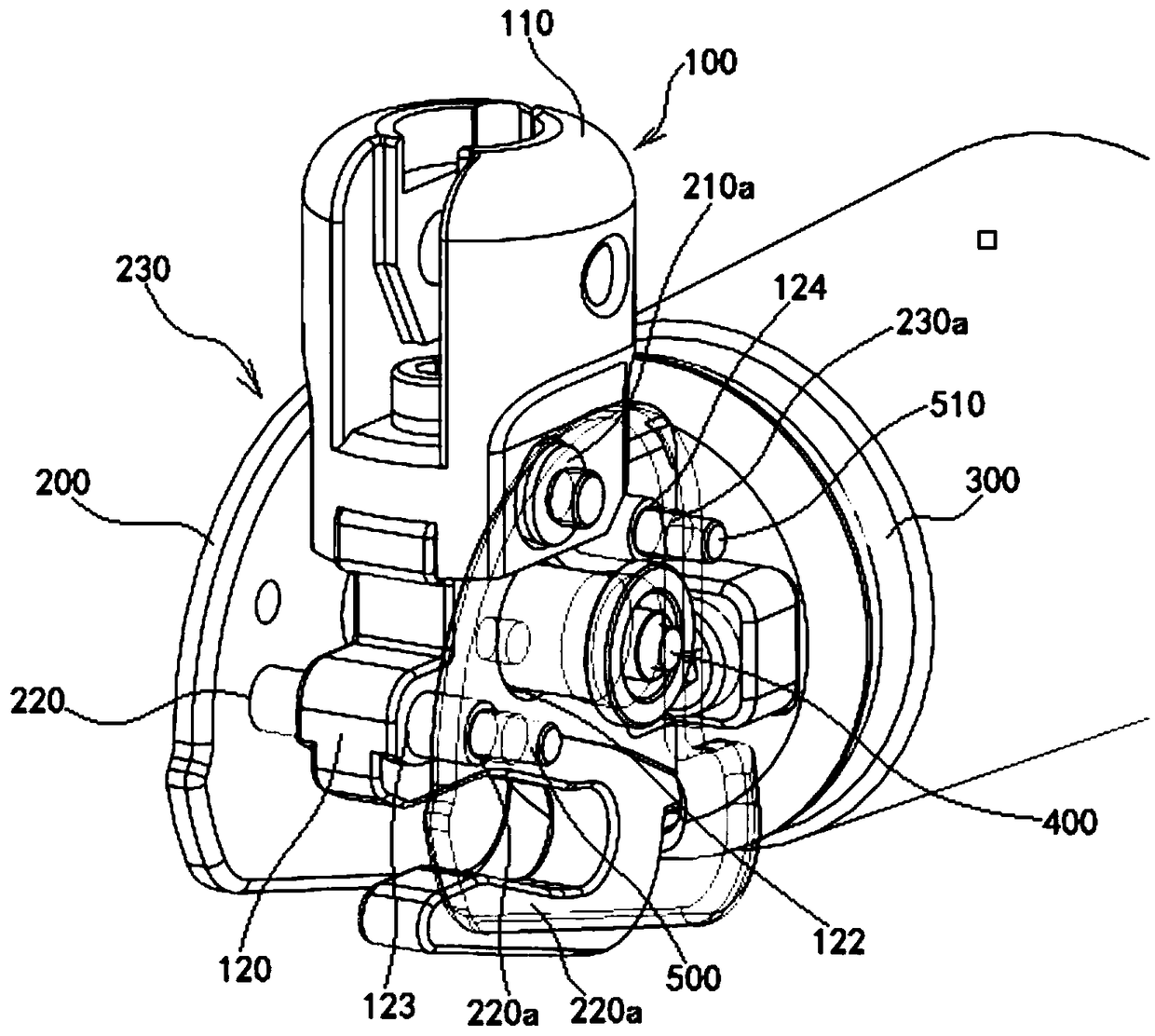

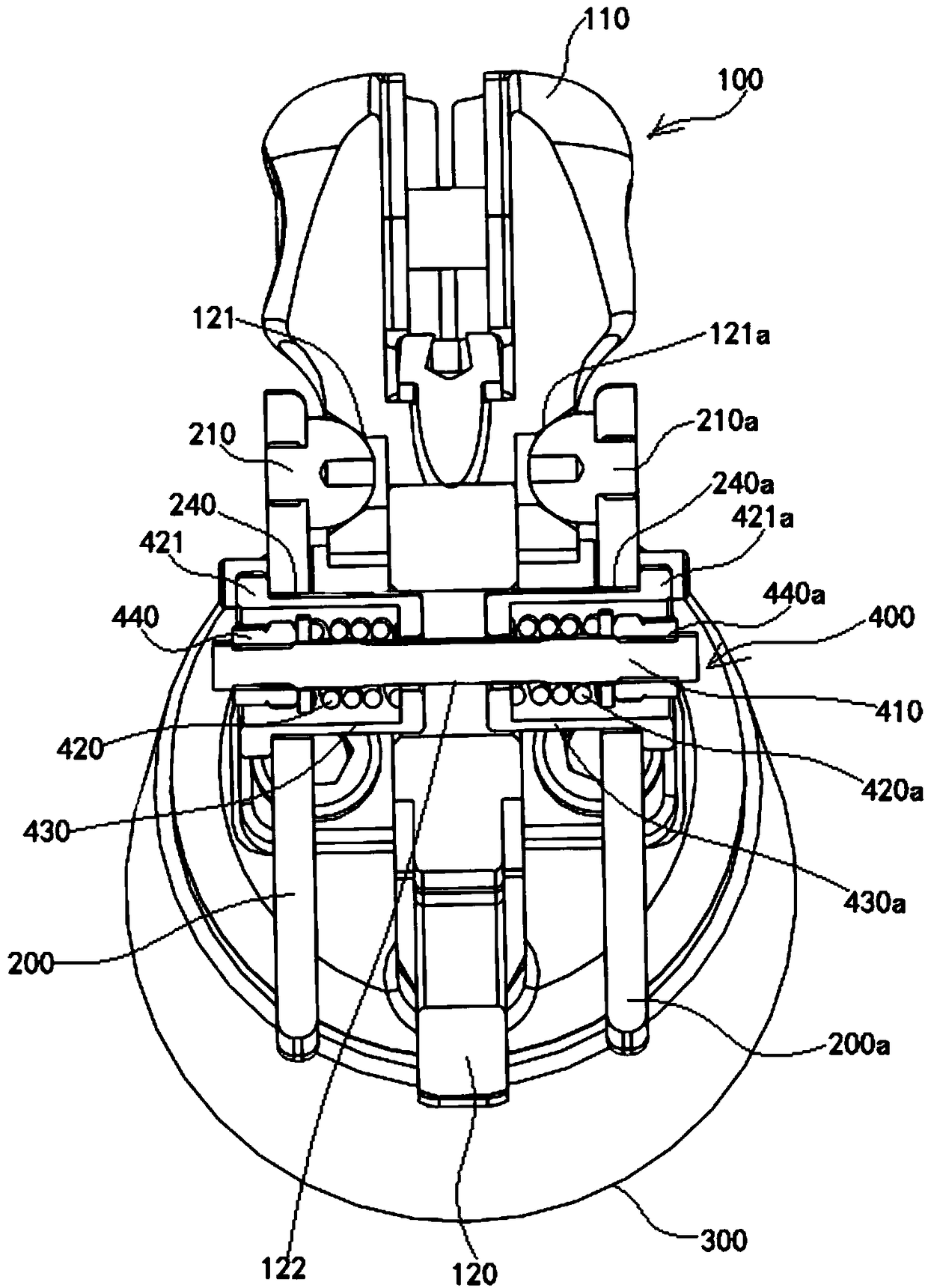

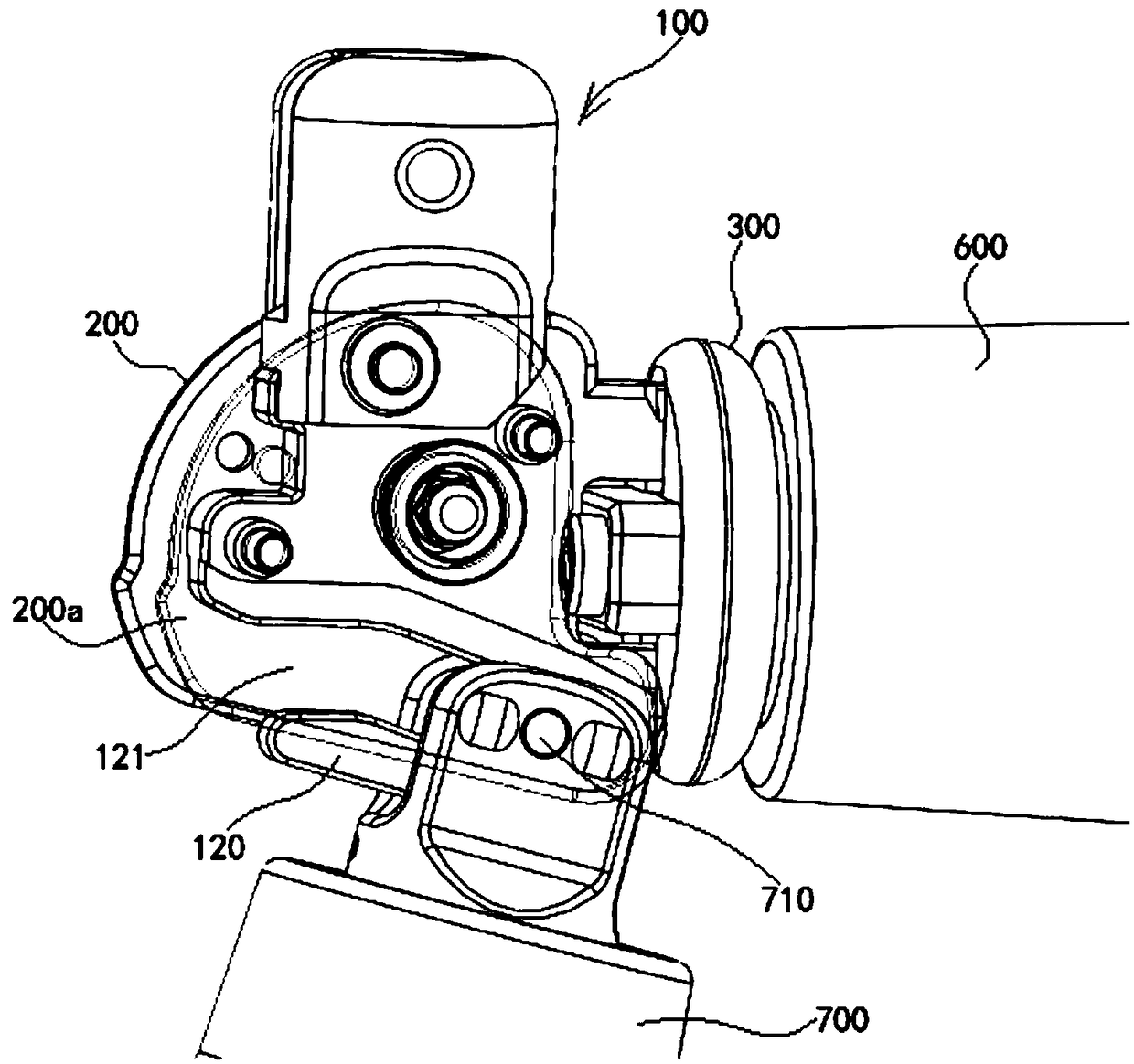

[0015] see figure 1 with figure 2 , an adaptive movable conductive connection mechanism shown in the figure, including a static contact seat 100, two conductive clips 200, 200a, a supporting insulator 300, a clamping spring assembly 400 and two positioning pins 500, 510.

[0016] The static contact seat 100 includes a conductive seat 110 and a guide seat 120, the conductive seat 120 is fixed on the guide seat 120 by fasteners, and the guide seat 120 is installed on the support insulator 300; inner tapered holes are respectively provided on both sides of the conductive seat 120 121, 121a, the inner tapered holes 121, 121a are V-shaped in radial section.

[0017] A mounting hole 122 and two positioning pin mounting holes 123 , 124 are provided on the guide seat 120 for passing through the clamping spring assembly 400 and the two positioning pins 500 , 510 .

[0018] A positioning pin 500 , 510 is installed in each of the two positioning pin mounting holes 123 , 124 .

[0019...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com