Connection structure between moving spring part and base of magnetic latching relay

A technology of magnetic latching relays and moving springs, applied in electromagnetic relays, electromagnetic relay details, relays, etc., can solve the problems of low consistency and large variation in positioning methods, and achieve the goal of improving positioning accuracy and avoiding accumulated tolerances. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

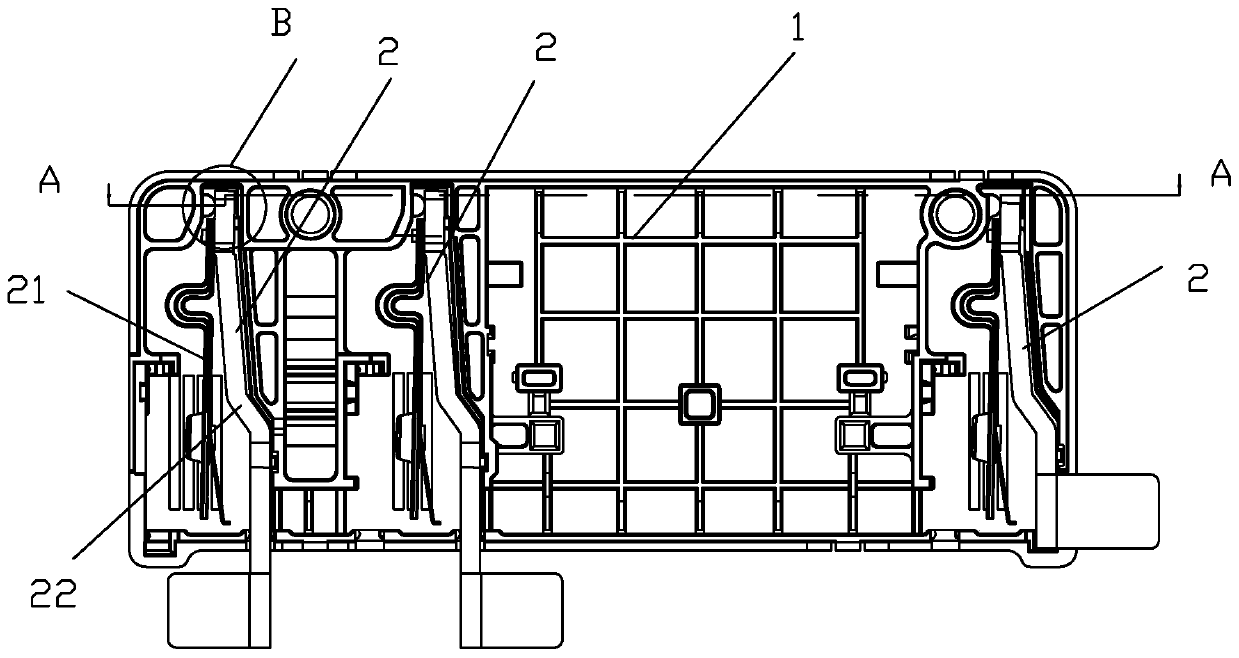

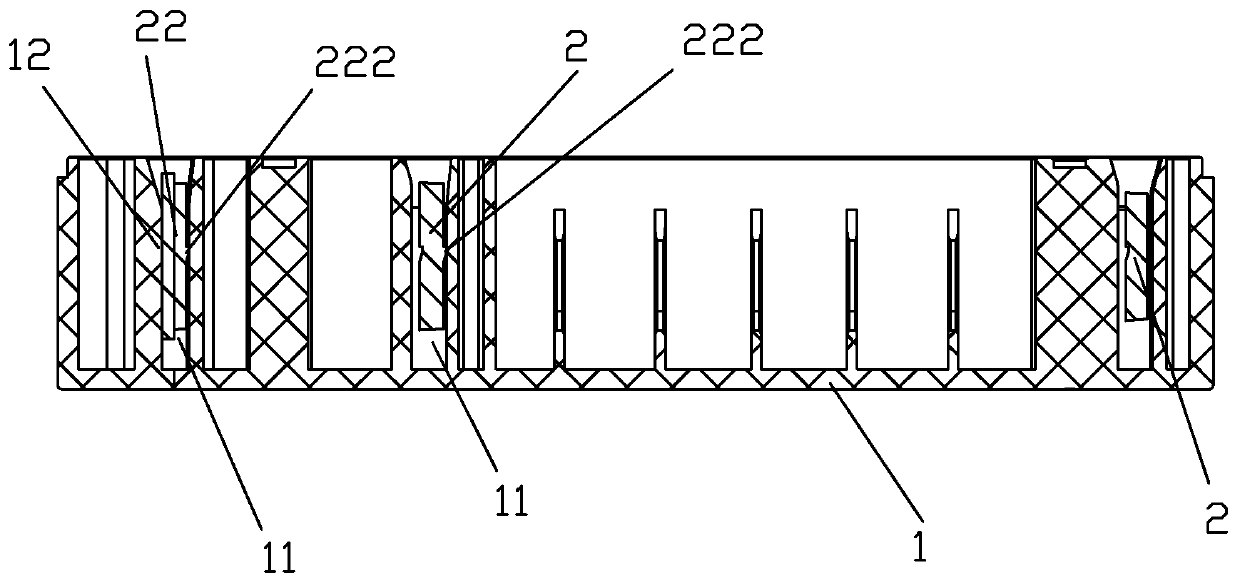

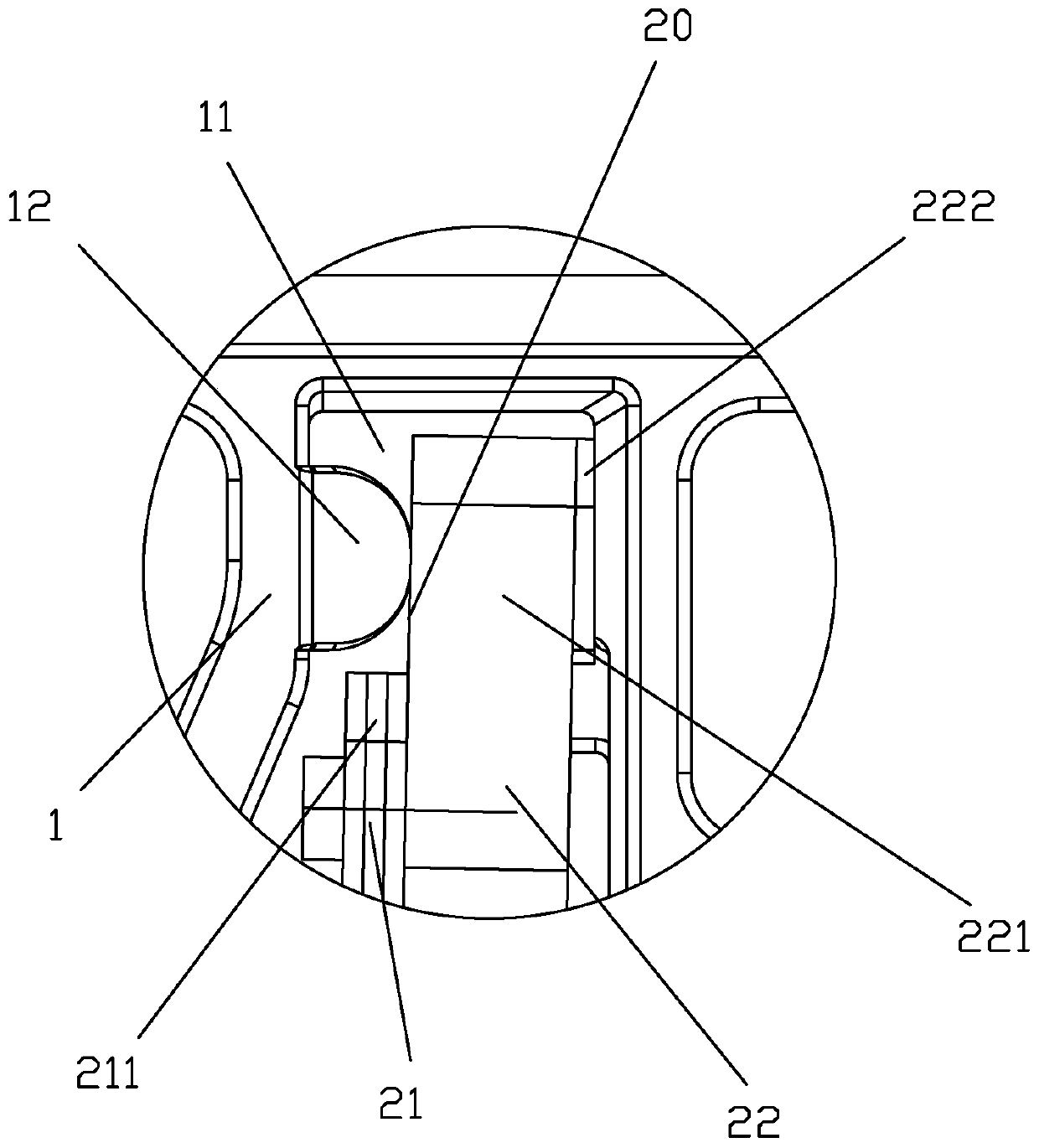

[0024] see Figure 1 to Figure 6 As shown, the connection structure between the moving spring part and the base of a magnetic latching relay of the present invention includes a moving spring part 2 and a base 1; the moving spring part 2 includes a moving reed 21 and a moving spring lead-out piece 22, one end 211 of the moving reed 21 is fixed to one end 221 of the moving spring lead-out piece 22; the base 1 is provided with a slot 11; One side of the thickness of one end 221 of 22 is connected and makes the end of one end 221 of the moving spring lead-out piece longer than the end of one end 211 of the moving reed by a distance 20; in the slot 11 of the base, One side corresponding to the thickness of the moving spring lead-out piece 22 is provided with a rib 12, when the moving spring part 2 is matched with the slot 11 of the base 1, the rib 12 of the slot of the base 1 is used as a positioning reference plane against the The distance between the end 221 of the movable sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com