DC charging pile charging method based on module maximum current output and shift

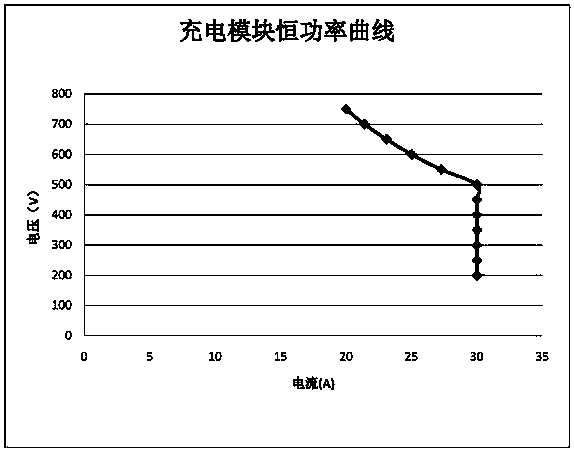

A DC charging pile, maximum current technology, applied in transportation and packaging, battery circuit devices, current collectors, etc., can solve the problems of poor operation status of the charging module, shortened working life of the module, and high power factor, to reduce standby loss, The effect of improving working life and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with embodiment the present invention is further described.

[0019] A DC charging method based on module maximum current output and shift, comprising the following steps:

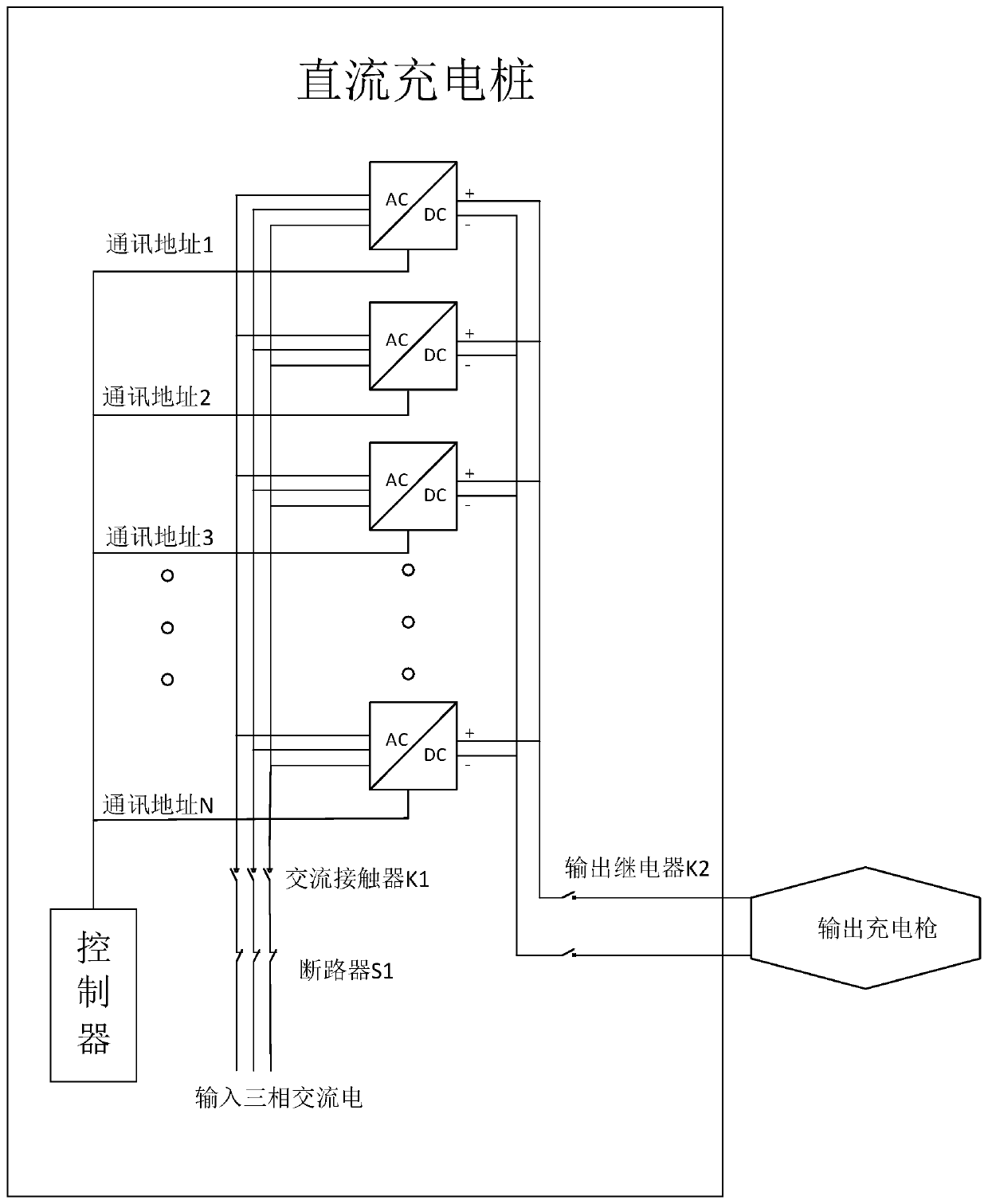

[0020] A. The DC charging pile is equipped with M charging modules, and the charging modules are connected in parallel. The AC input terminal of the charging module is connected to the electrical circuit, and the DC output terminal of the charging module is connected to the DC output circuit; the three-phase alternating current passes through the circuit breaker S1 and The AC contactor K1 is connected to the electrical circuit, and the charging pile S1 that is put into use is closed. When the charging gun of the DC charging pile is inserted into the charging interface of the electric vehicle, the AC contactor K1 is closed. When the charging stops, K1 is disconnected to reduce the number of charging modules. standby loss;

[0021] B. The main controller of the DC charging pile a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com