Ball grid array printed circuit board

A printed circuit board and ball grid array technology applied in the electronic field to achieve the effects of improving portability, improving component integration, and increasing effective wiring area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0024] In order to reduce the number of openings on the ball grid array printed circuit board, increase the effective wiring area of the circuit board, improve the integration of circuit board components, reduce the volume of the circuit board, improve the portability of electronic equipment, and improve the use of electronic equipment by users. Equipment satisfaction, this embodiment provides a new ball grid array printed circuit board.

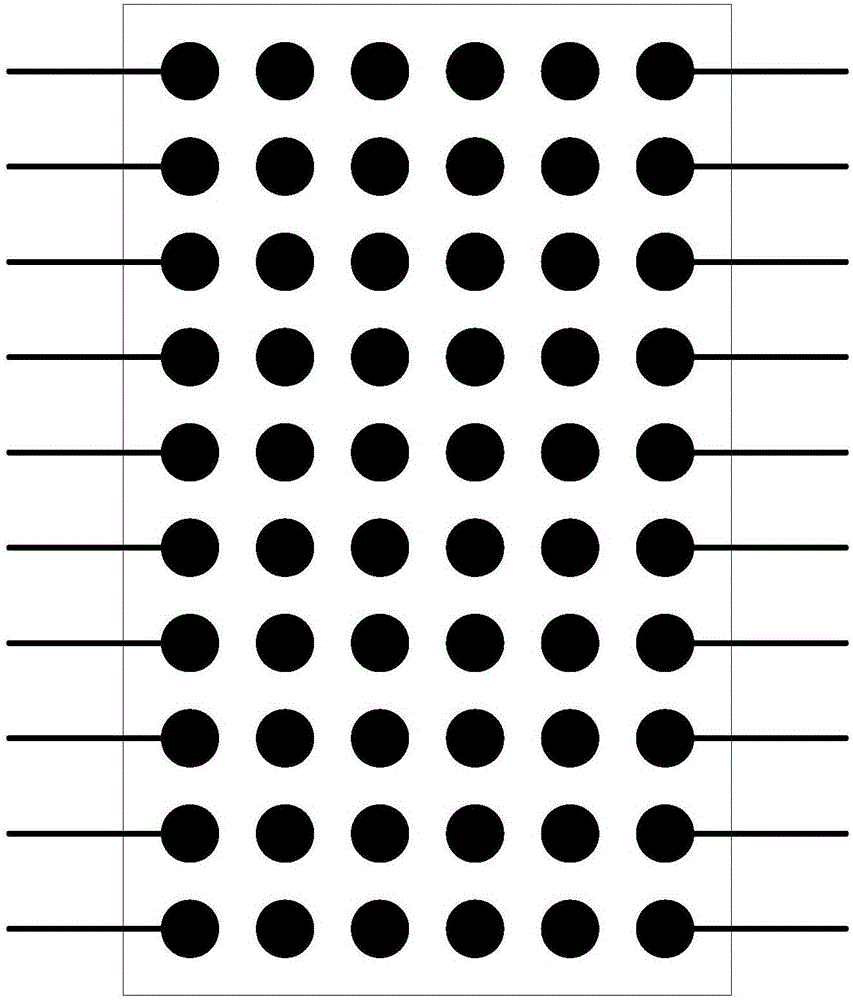

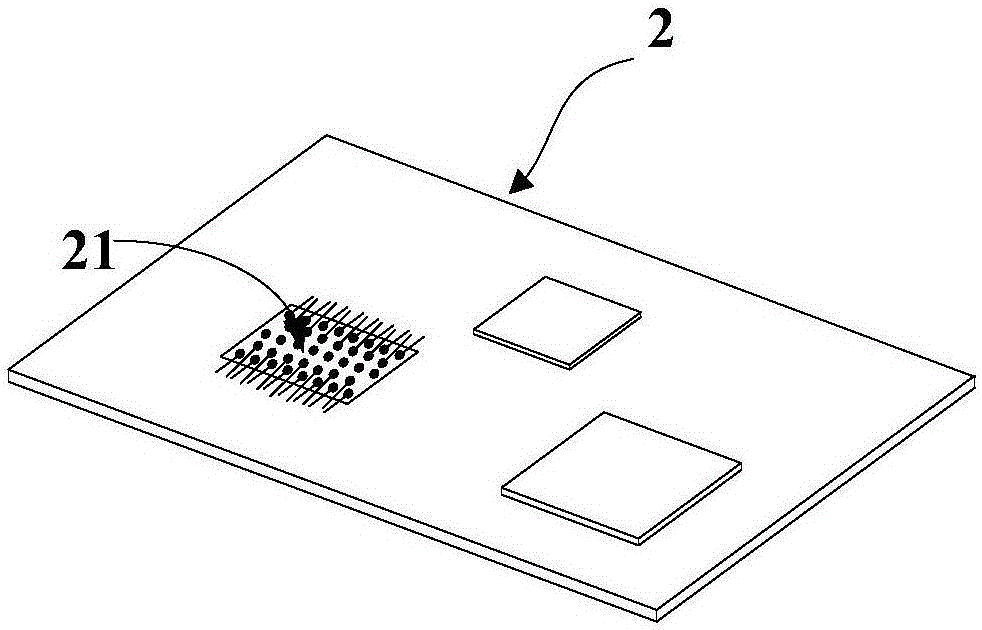

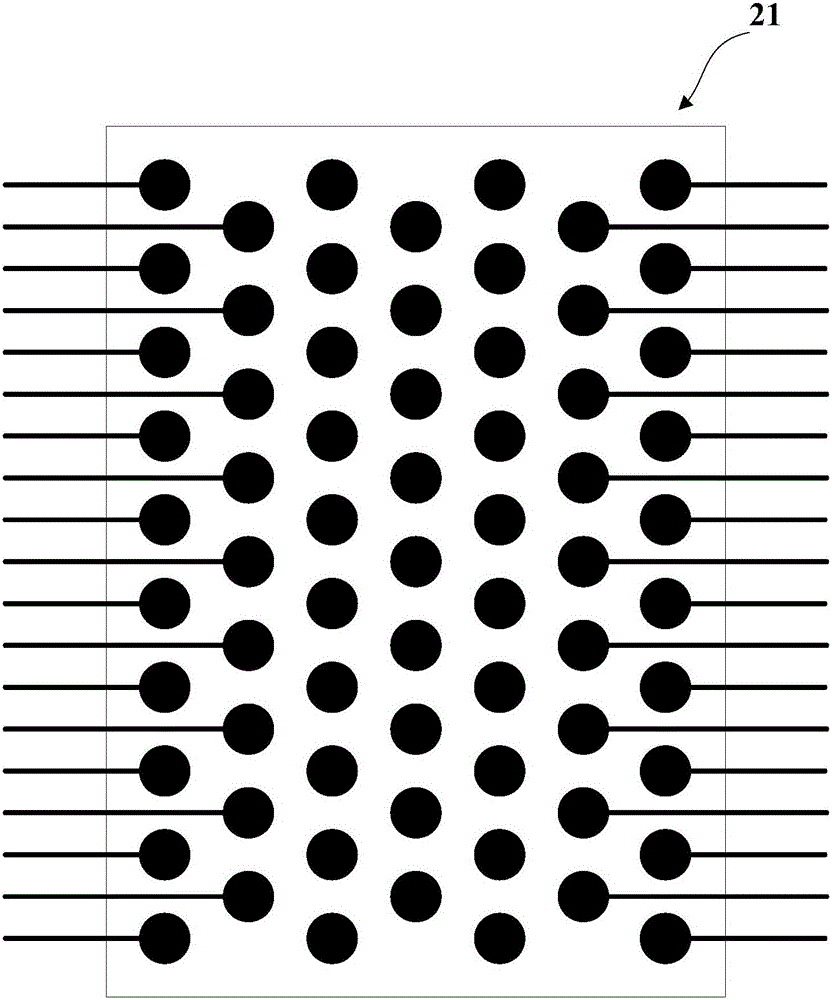

[0025] refer to figure 2 , figure 2 It is a schematic diagram of the structure of the BGA printed circuit board provided by the first embodiment of the present invention. The BGA printed circuit board 2 includes a first pad array 21 . Wherein, the structure of the first pad array 21 can be referred to image 3 , including n pad queues (n≥2), each pad queue is recorded as the first pad queue, the second pad queue, ..., the nth pad queue according to the order from near to far from the outlet side .

[0026] It should be understood tha...

no. 2 example

[0044] In this embodiment, on the basis of the first embodiment, the present invention will be further described by taking the way that each third pad in the third pad array goes out on the surface of the BGA printed circuit board as an example.

[0045] refer to Figure 6 , Figure 6 A schematic diagram of the structure of a first pad array provided by the second embodiment of the present invention, wherein each pad in the second pad array is alternately arranged with each first pad in the first pad array, and the third pad The third pads in the pad alignment are alternately arranged with the second pads in the second pad alignment. When going out, the third pad comes out from between the two adjacent second pads, and is parallel to the outgoing line of one of the second pads, and connects from the two first pads adjacent to the second pad. pass between plates.

[0046] It is worth noting that when going out, the distance between two adjacent second pads should be greater ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com