Bulk store

A technology for storage, bulk materials, applied in the direction of transportation and packaging, loading/unloading, etc., to achieve cost reduction, width reduction, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

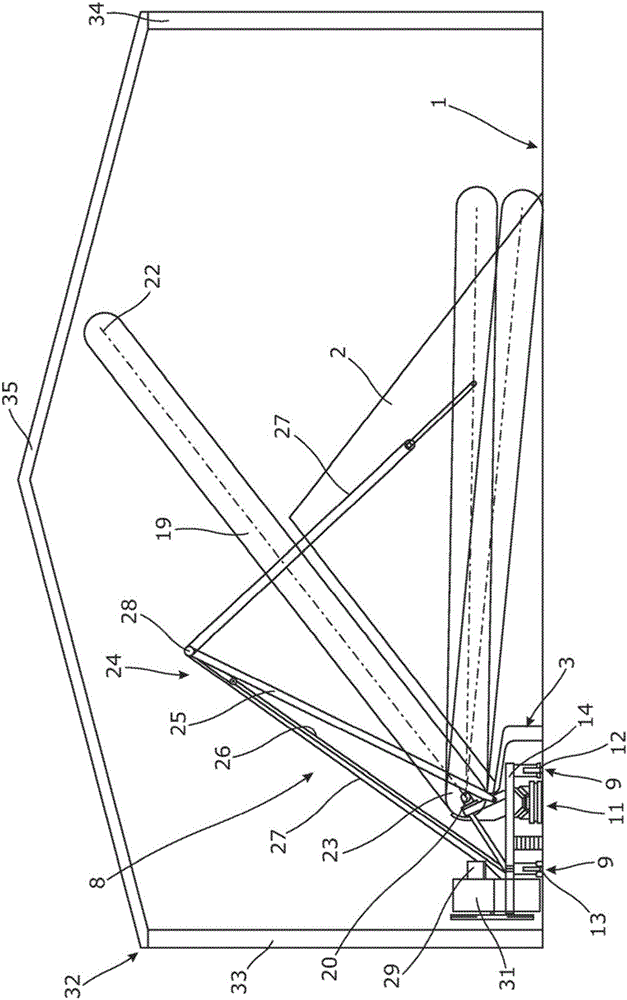

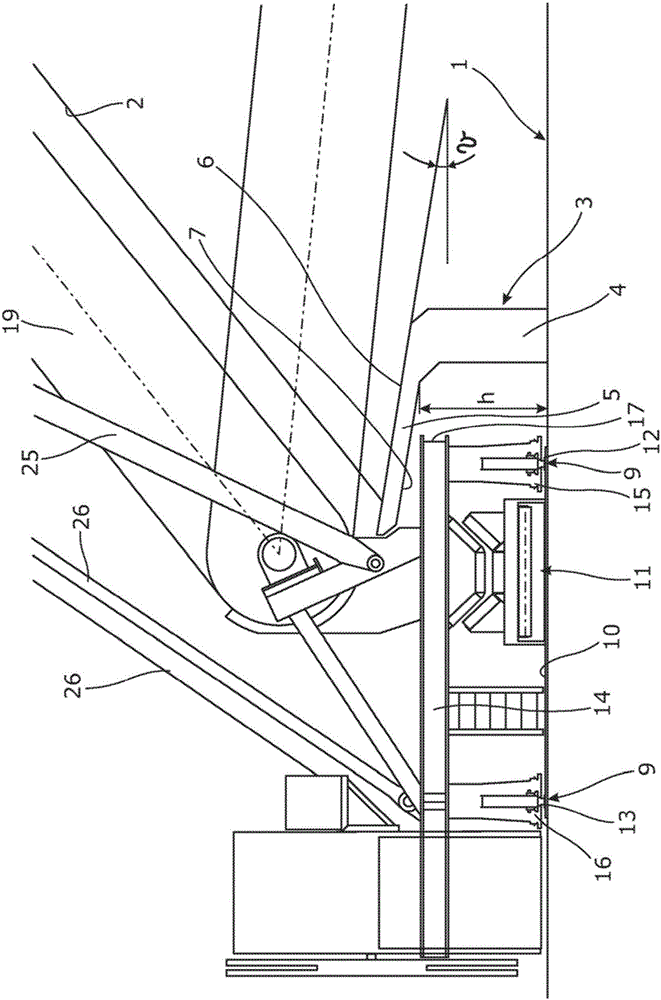

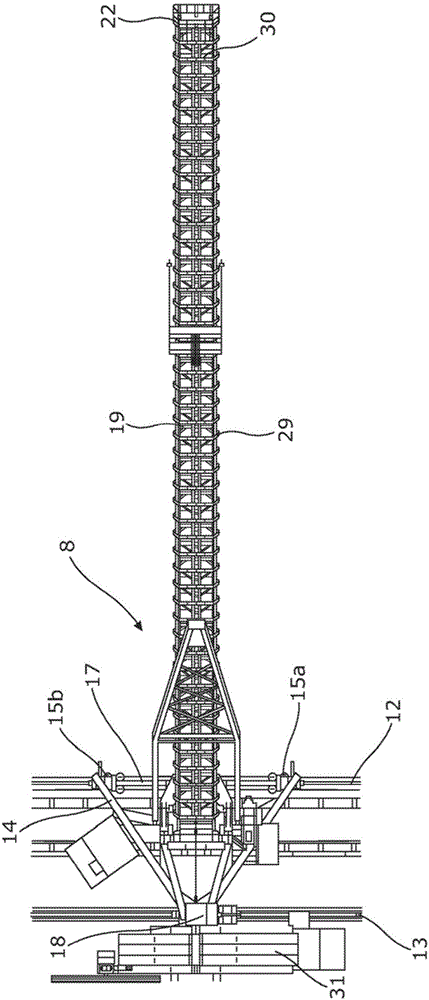

[0023] The bulk storage according to the invention comprises a bulk storage area 1 for storing bulk material stacked in at least one pile 2 . The bulk storage is laterally delimited by delimiting walls 3 . The bounding wall 3 includes an upright lower wall portion 4 having inner and outer surfaces, and an upper wall portion 5 extending outwardly away from the bulk storage area 1 at an upper end of the upright lower wall portion 4 as an extension of the upright lower wall portion 4 . The upper wall portion 5 has an outwardly and upwardly sloping upper surface 6 and a lower surface 7 . The inclination angle v of the upper surface 6 of the upper wall portion 5 in the present embodiment is approximately 9°.

[0024] The bulk storage also includes a bulk material recovery device 8 and a belt conveyor 11, the bulk material recovery device 8 is in the form of a side scraper movable along and parallel to the boundary wall 3, arranged in the bulk storage area 1 The belt conveyor 11 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com