Suspended-grinding fertilizer applicator

A fertilizer applicator and suspension mill technology, which can be applied to fertilizer applicator, liquid fertilizer distribution, pressurized spreading method of liquid fertilizer, etc., can solve the problems of uneven fertility, increased production cost, and poor control of chemical fertilizer dissolution effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

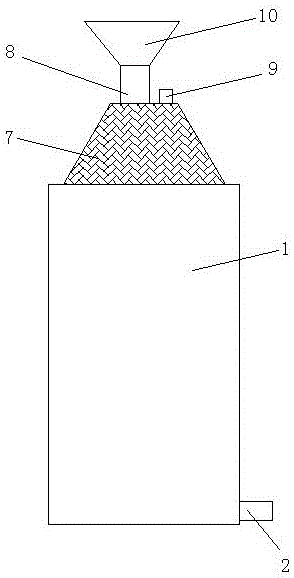

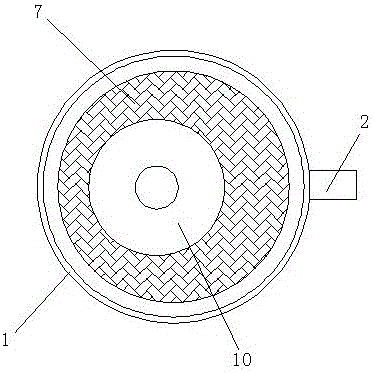

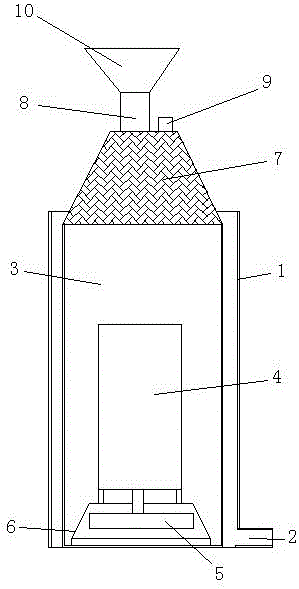

[0012] Example 1, such as figure 1 , figure 2 and image 3 As shown, a hanging mill fertilizer applicator includes a cylindrical outer barrel 1 made of plastic material, the top of the outer barrel 1 is open, the bottom of the outer barrel 1 is provided with a fertilization outlet 2, and the outer barrel 1 is provided with a A cylindrical inner barrel 3 made of plastic material, the upper top surface of the inner barrel 3 is lower than the upper top surface of the outer barrel 1, there is a gap between the outer cylindrical surface of the inner barrel 3 and the inner cylindrical surface of the outer barrel 1, and the interior of the inner barrel 3 is provided with a grinding Device 4, the grinding device 4 is a motor, the motor shaft of the motor is perpendicular to the bottom surface of the inner barrel 3, the motor shaft is provided with a grinding wheel 5, the motor bottom is provided with a bracket 6, and the grinding wheel is illuminated in the bracket 6, and the bracke...

Embodiment 2

[0013] Embodiment 2: In this embodiment, only the bottom of the original outer barrel is connected with the bottom of the inner barrel, so that the outer barrel and the inner barrel are integrated, and other technical solutions are not changed. This improvement makes the device more compact.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com