Shoe capable of increasing air flowing at the bottom of shoe cavity

A gas flow, shoe technology, applied in the direction of soles, uppers, footwear, etc., can solve the problems of air permeability limitation, exhaust gas obstruction, and reducing the safety of foot sole protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

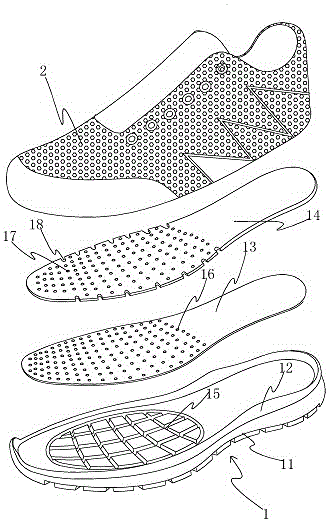

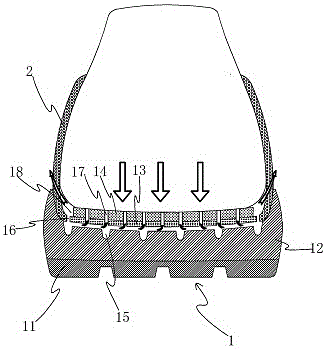

[0012] refer to Figure 1 to Figure 2 , the embodiment of the present invention discloses that a shoe that can increase the gas flow at the bottom of the shoe cavity includes a shoe sole 1 and a shoe upper 2 arranged on the shoe sole. The shoe sole 1 includes a large bottom 11 and a middle Bottom 12, midsole board 13 on the midsole and insole 14 on the midsole board, the upper surface of the forefoot part of the midsole 12 is provided with grid-like exhaust grooves 15, and the grid-like rows The groove width of the air groove 15 is 3.5mm, the groove depth is 3mm, and the grid width formed in the grid-like exhaust groove 15 is 28mm; The first air hole 16; the forefoot of the insole 14 is provided with a plurality of second air holes 17 running through its upper and lower surfaces; the first air hole 16 is connected to the grid-shaped exhaust groove 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove width | aaaaa | aaaaa |

| Groove depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com