Connecting structure, filter core assembly and water purifying device

A connection structure and filter element technology, which is applied in filtration separation, membrane filter, filtration treatment, etc., can solve the problems of cumbersome and complicated core replacement operations, improper installation of filter elements, and damage to the connection structure, and achieve convenient and labor-saving operation and a mechanical connection process. Effortless and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to further explain the technical means and functions adopted by the present invention to achieve the predetermined purpose, the specific implementation, structure, features and functions of the application according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. In the following description, particular features, structures, or characteristics of one or more embodiments may be combined in any suitable manner.

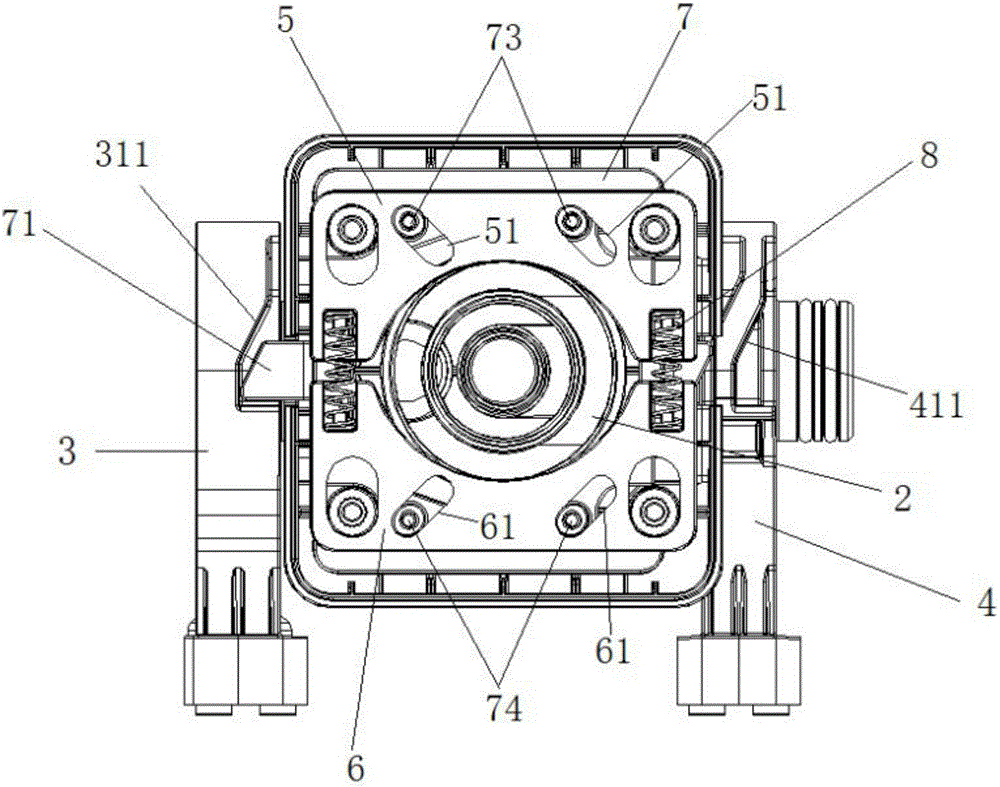

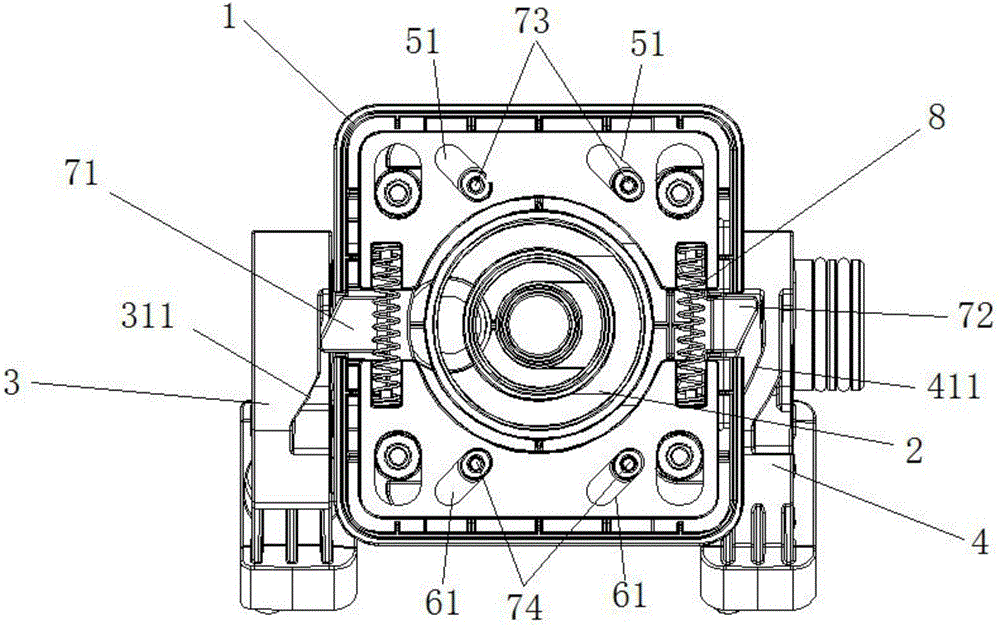

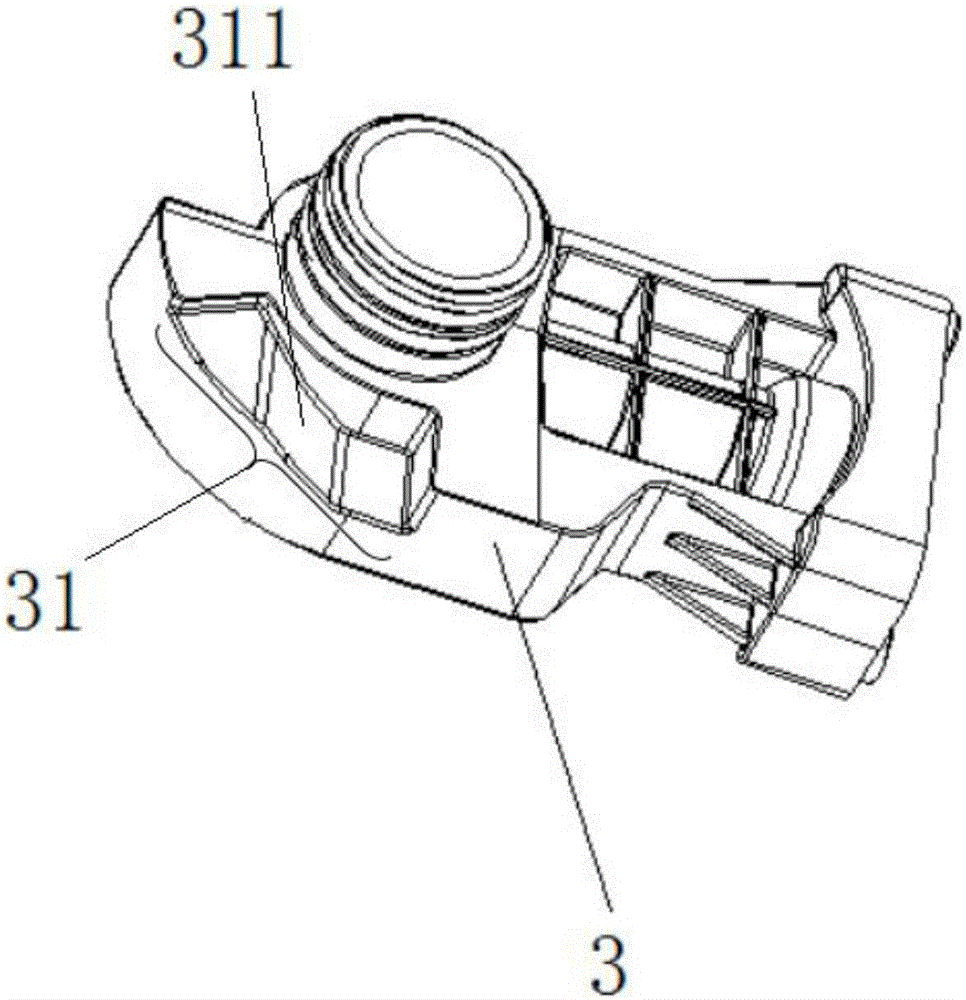

[0051] Such as figure 1 with figure 2 As shown, this specific embodiment relates to a connection structure, including a bracket unit and an adapter unit 1 that is rotatably connected to the bracket unit, defining the rotation axis of the adapter unit 1 as the main axis (such as Figure 16 shown in the B-B connection);

[0052] The adapter unit 1 includes a plurality of clamping pieces, and an installation gap 2 is formed between the multiple clamping pieces;

[0053] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com