Automobile steel ring positioning and grinding device

A technology of automobile steel and output shaft, which is applied in the direction of grinding/polishing safety devices, grinding machines, grinding workpiece supports, etc. It can solve the problems of troublesome clamping process, inconvenient installation, uneven force, etc., and achieves simple structure, Cost saving and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

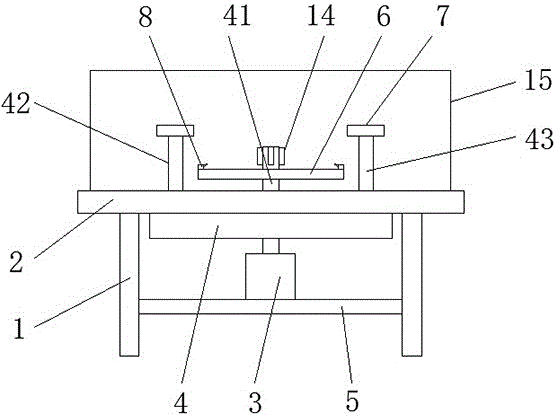

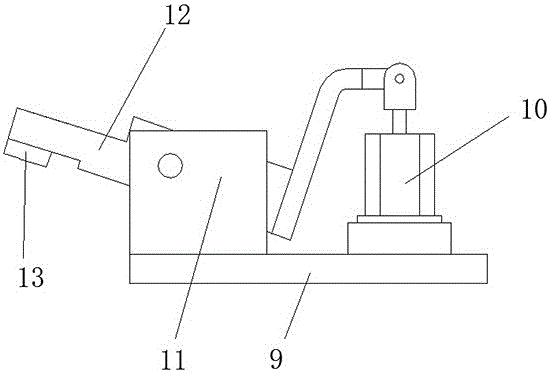

[0020] A kind of automobile rim positioning grinding device according to the present invention, such as figure 1 As shown, it comprises: frame 1, table top 2, motor 3, gearbox 4; said table top 2 is arranged on the top of frame 1; 4 is located at the bottom of the table 2 and is connected with the main shaft of the motor 3; the gearbox 4 is provided with a first output shaft 41, a second output shaft 42 and a third output shaft 43; the second output shaft 42 and the second output shaft The three output shafts 43 are symmetrically arranged on both sides of the first output shaft 41; the upper end of the first output shaft 41 is fixedly provided with a positioning rotating disk 6; the upper ends of the second output shaft 42 and the third output shaft 43 are fixedly provided with a polishing Wheel 7; the edge of the positioning rotating disk 6 is provided with evenly distributed compression modules 8 in the circumferential direction, and the number of compression modules 8 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com