Natural latex pillow automatic production line

An automatic production line and natural latex technology, applied in pillows and other directions, can solve the problems of large floor space and low production efficiency of natural latex pillow production lines, and achieve the effect of being beneficial to popularization, improving production efficiency and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

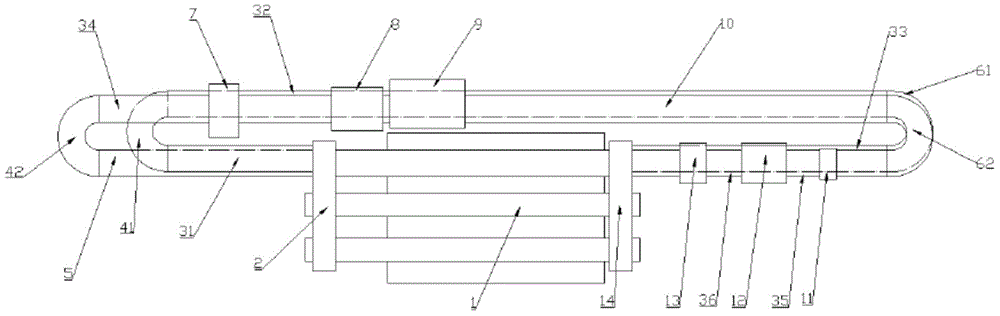

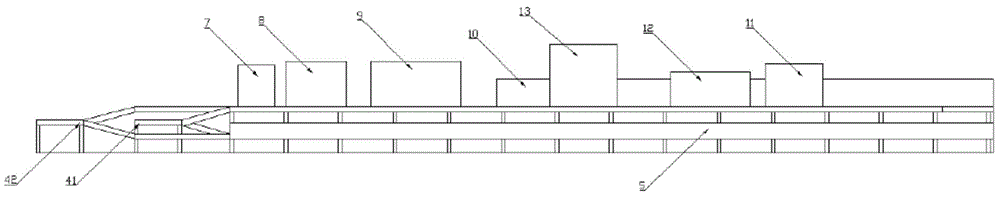

[0024] Such as Figure 1~Figure 2 Shown, a kind of natural latex pillow automatic production line, it comprises transplanting machine, conveying device and the oven line 5 of the natural latex pillow that is used for vulcanization and drying the natural latex pillow after glue injection and is used for cooling and cleaning the natural latex pillow mold after molding Cooling line 10, described transplanting machine comprises first transplanting machine 2 and second transplanting machine 14, between oven line 5 and cooling line 10, connect end to end through conveying device, described conveying device is made up of turning roller table, transition The roller table, the rotating lifting transport part 42 and the rotating descending transport part 41 are composed of, and are characterized in that:

[0025] The cooling line 10 is arranged above the oven line 5, the beginning of the oven line 5 is connected to the first transplanter 2 through a conveying device, the tail of the ove...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap