Motor train unit head train passive safety protection device

A protective device and passive safety technology, applied in traction devices, railway vehicle wheel guards/buffers, transportation and packaging, etc., can solve unreasonable local strength requirements of the car body, large ratio of peak force to average force, and energy absorption The problem of low energy absorption efficiency of the device can solve the problems of low or insufficient absorption efficiency, guarantee the safety of life and property, and reduce maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

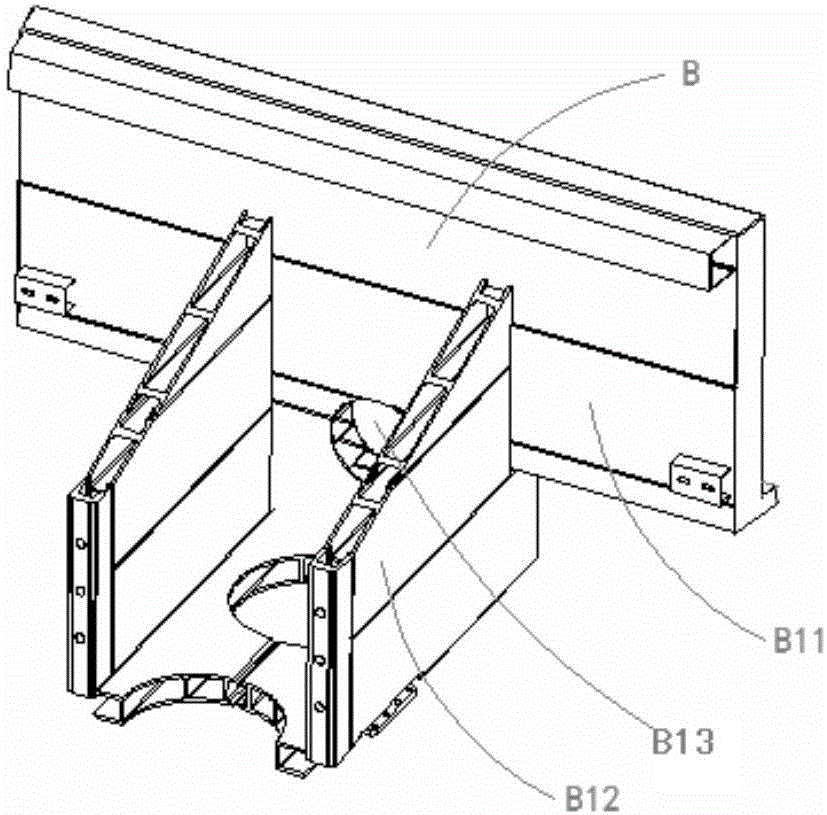

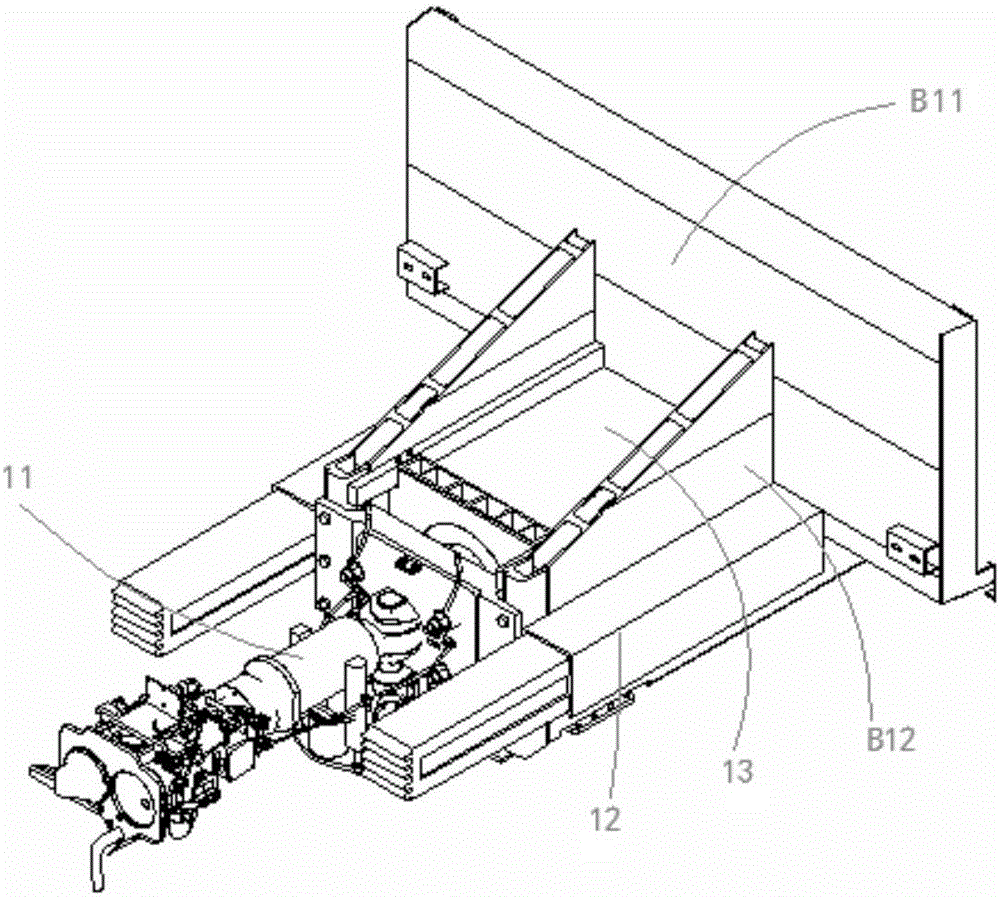

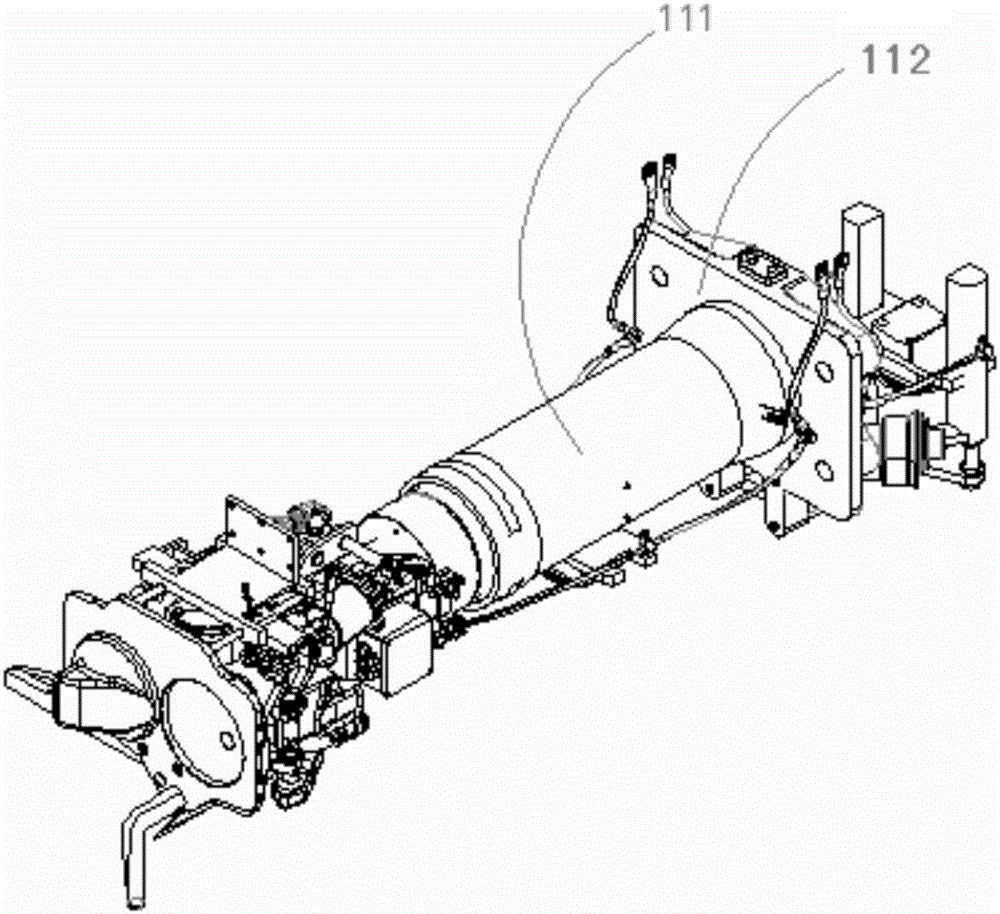

[0032] Such as figure 1 , 2 As shown: the protection device of the present invention is installed on the front end of the anti-collision plate B11 of the head car body B, and the protection device is installed on the head car body B as a structure that can be flexibly disassembled and replaced. In the event of an accident, the protective device is responsible for collision energy absorption. During the whole process, it should ensure that the body B of the leading vehicle does not undergo severe crushing and deformation, that is, ensure the living space of passengers. The protection device is composed of a coupler buffer assembly 11, an anti-climber assembly 12, and a main energy absorber assembly 13; wherein, the main energy absorber assembly 13 is installed on the front end of the anti-collision plate B11 of the body B of the leading vehicle; The coupler buffer assembly 11 is arranged in front of the main energy absorber assembly 13, and is installed on the two side guard p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com