Automatic speed regulating mechanism of construction hoist

A technology for automatic speed regulation of construction elevators, applied in elevators, transportation and packaging, etc., can solve the problems of slow speed adjustment of construction elevators, easy judgment errors, safety accidents, etc., and achieve simple structure, prevent overloading of elevator cages, and stable lifting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

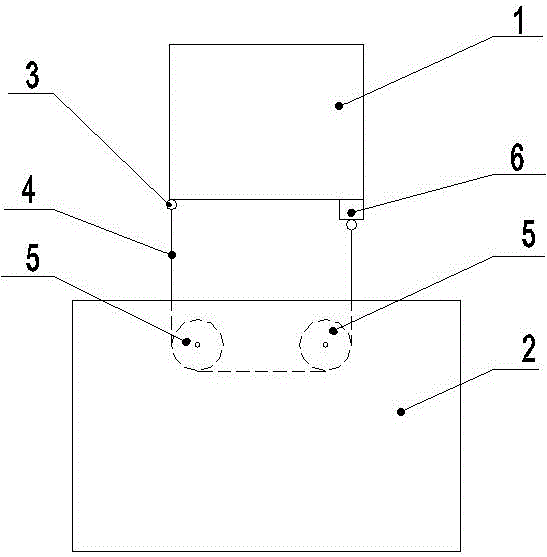

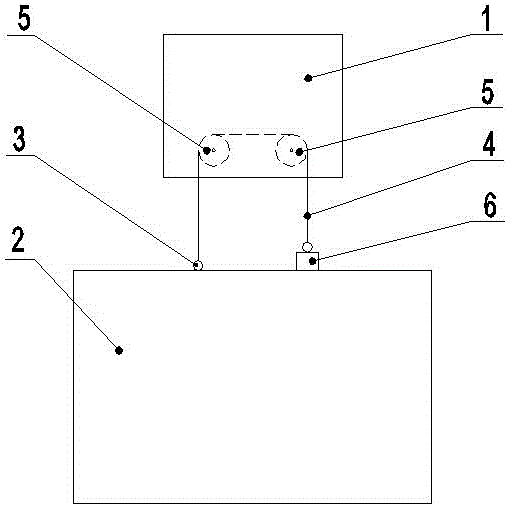

[0014] The construction hoist includes a tower body, a transmission frame 1, a transmission assembly, a lifting cage 2, a cable follower system, an electrical control system, and a wall support. The tower body is welded into standard sections by seamless steel pipes and angle steels. Racks are installed on the standard sections, and the upper and lower sections can be interchanged. The multi-section standard sections are connected by bolts. fixed. The lifting cage 2 is composed of a chassis, a protective fence bar, four sets of guide pulleys, a cage door, and a control room. An anti-fall device is installed on the protective fence bar, a buffer spring is installed on the chassis, and a control box is installed in the control room. The top of the cage 2 is equipped with a support seat and a protective fence bar. Lifting cage 2 moves vertically along the seamless steel pipe on the tower body to transport construction personnel and materials. The transmission frame 1 is a steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com