Vertical axis wind turbine with protective sleeve

A technology for wind turbines and protective sleeves is applied to wind turbines, wind turbine combinations, wind turbines at right angles to the wind direction, etc., and can solve the problems of small starting torque of wind turbines, low utilization rate of wind energy, and lack of attention. Achieve the effect of reducing the influence of the power grid, reducing the wind area and reducing the speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

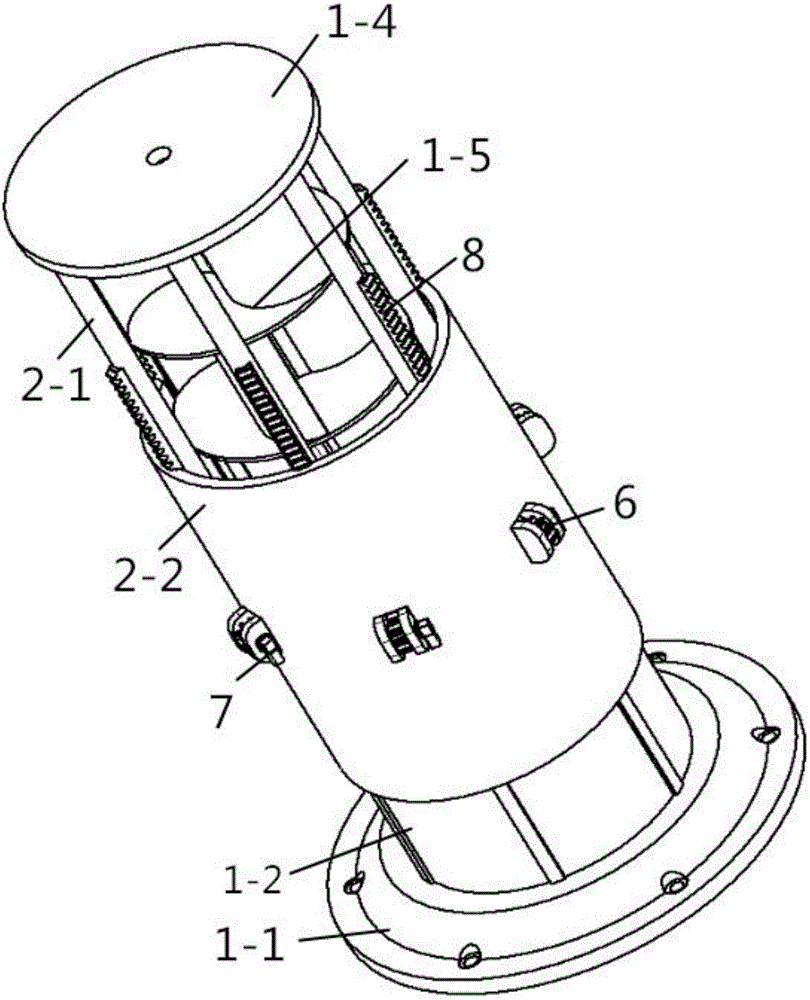

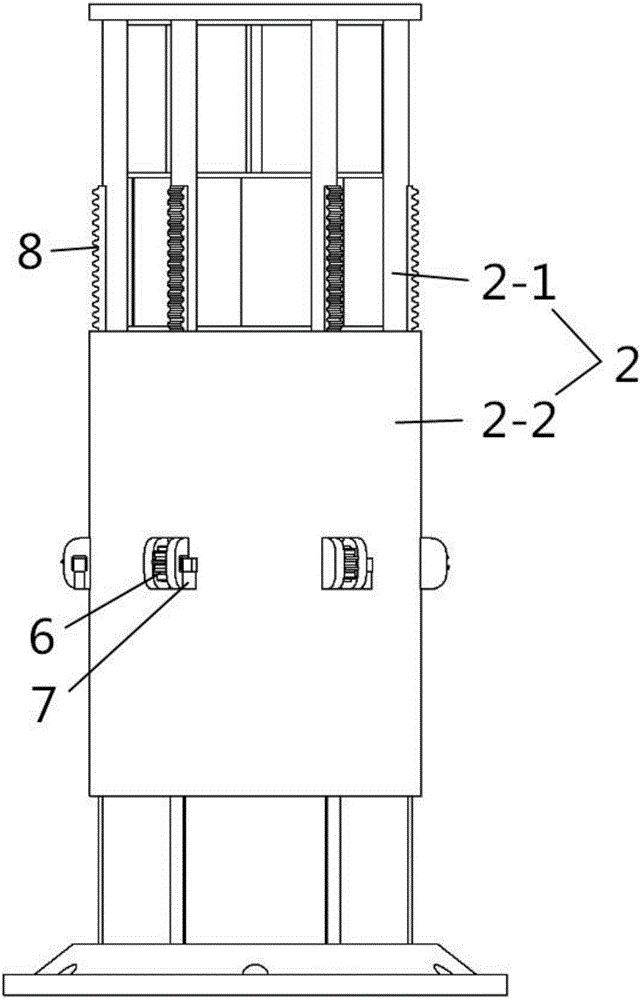

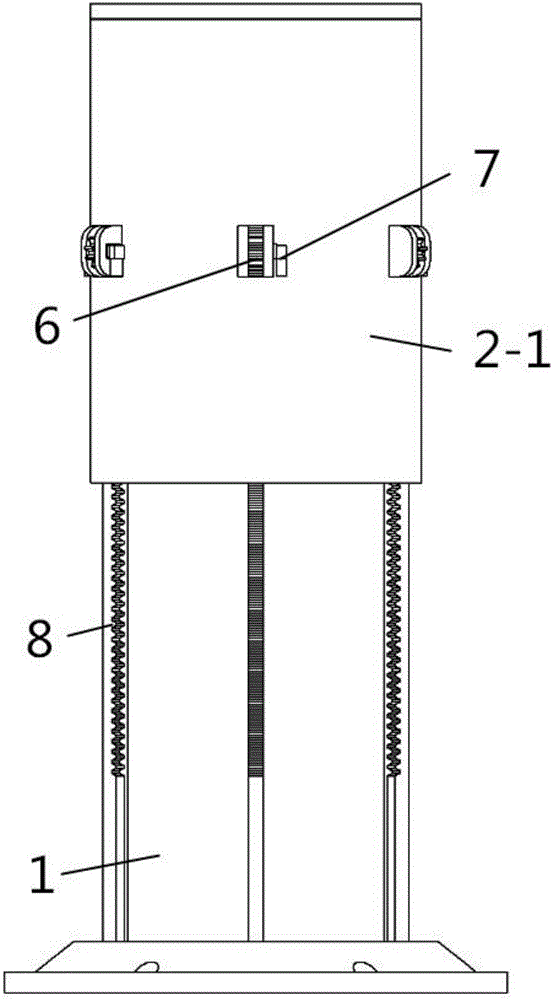

[0029] See Figure 1 to Figure 7 As shown, the vertical axis wind power generator with a protective cover in this embodiment includes a power generation device 1 and a protective device 2 .

[0030] The power generation device 1 includes a base 1-1, a cylinder 1-2 disposed on the base 1-1, a support shaft 1-3 disposed on the upper end of the cylinder 1-2, and a top cover 1 disposed on the support shaft 1-3 -4, the supporting shaft 1-3 is sleeved with a wind turbine 1-5 connected in rotation. A generator 3, a rotational speed sensor 4 and a PLC controller 5 are arranged inside the cylinder body 1-2. The rotational speed sensor 4 detects the rotational speed of the wind turbine 1-5 and outputs a pulse signal to the PLC controller 5 . The PLC controller 5 collects the pulse signal output by the rotational speed sensor 4, and divides the number of pulse signals collected within a preset time by the preset time to obtain the rotational speed.

[0031] The protective device 2 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com