Drive circuit mounting structure of full sealed lamp

A technology for driving circuits and installation structures, which is applied in the directions of electric lamp circuit layout, circuit layout, electric light source, etc., can solve the problems of many assembly processes, many components, and high cost, and achieves the advantages of fewer parts, fewer assembly processes, and guaranteed sealing performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

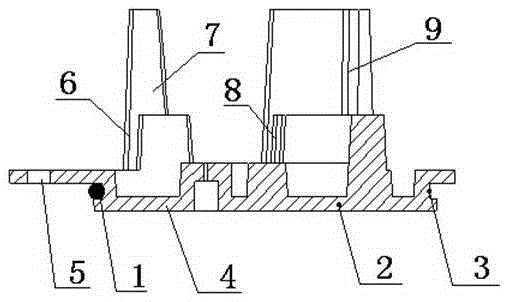

[0008] Depend on figure 1 It can be seen that it is the general assembly drawing of the end cover of the sealing tube of the lamp of this embodiment. The drive circuit installation structure of the fully sealed lamp consists of O-ring 1, rear cover 2, rear cover ring groove surface 3, lamp shell 4, lamp shell guide column 5, lamp shell hole column 6, lamp shell small platform, lamp shell round The ring surface 8 and the self-tapping screw 9 are composed. The O-ring 1 is set on the back cover 2, so that the ring groove surface 3 of the back cover is in contact with the O-ring 1, and the back cover 2 is installed on the lamp housing 4 along the guide column 5 of the lamp housing. , the lamp shell small platform 7 on the lamp shell 4 is in contact with the lamp shell annular surface 8, the self-tapping screw 9 is tapped into the lamp shell hole column 6, and the O-ring 1 is compressed and deformed to realize the sealing of the lamp. The O-ring is a national standard O-ring, with...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap