Measuring device for friction force between oil nozzle and needle valve

A measuring device and friction force technology, which is applied in measuring devices, force/torque/work measuring instruments, instruments, etc., can solve problems such as difficult friction force and inability to measure friction force between the nozzle and the needle valve, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with specific drawings and embodiments.

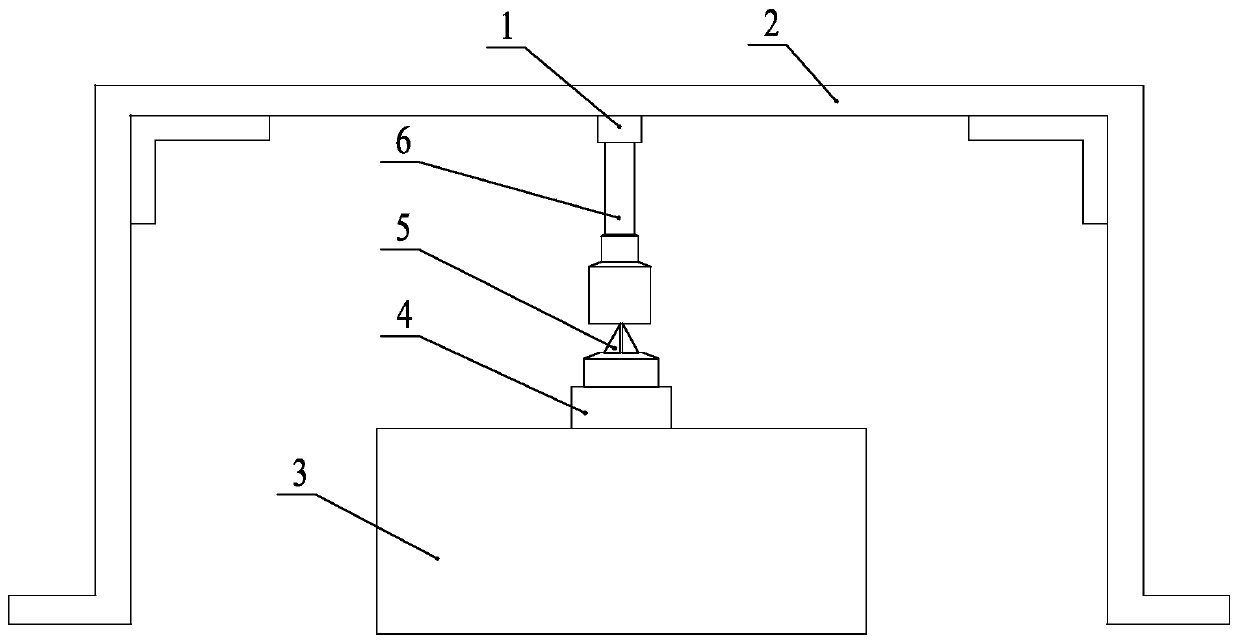

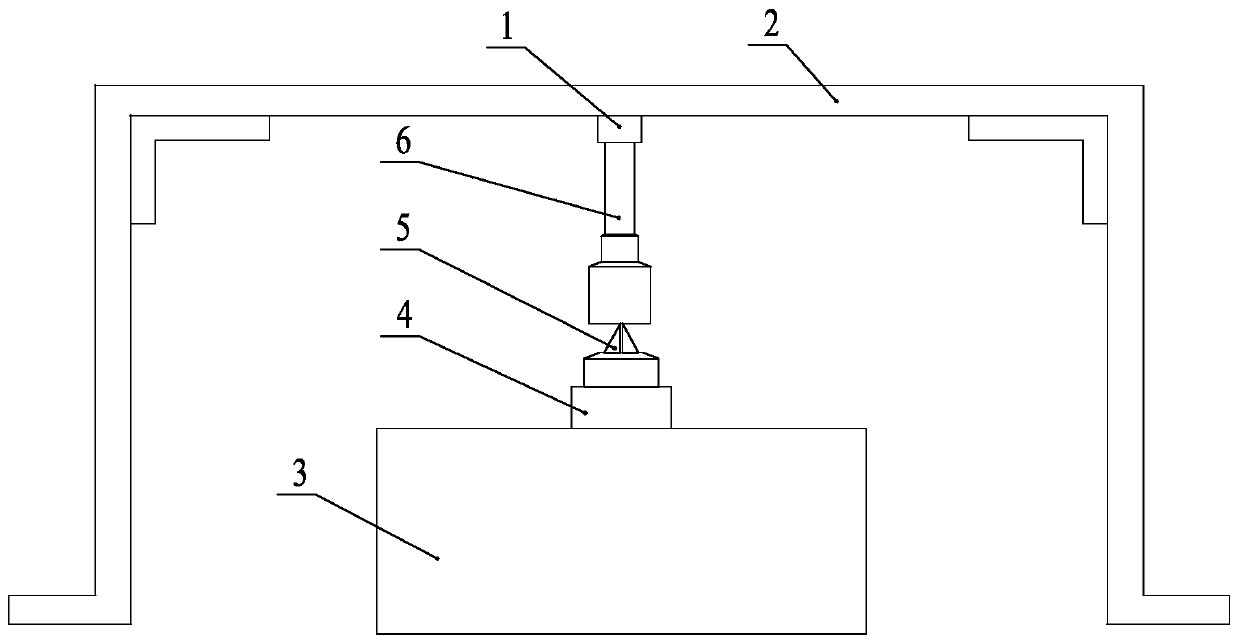

[0011] Such as figure 1 As shown, the measuring device for the friction between the oil nozzle and the needle valve in the embodiment is mainly composed of a force sensor 1, a bracket 2, a vibration test bench 3 and a needle valve fixture 4, and the needle valve fixture 4 is installed on the table of the vibration test bench 3 , the needle valve clamp 4 is used to clamp the needle valve 5; the upper end of the needle valve 5 is sleeved with the oil nozzle 6, and the upper end of the oil nozzle 6 is rigidly connected to the force sensor 1, and the force sensor 1 is installed at the bottom of the bracket 2, and the The height of the bracket 2 can be adjusted to make the reading of the force sensor 1 return to zero due to its own weight; the vibration test bench 3 drives the needle valve 5 to move up and down, simulating the motion state of the needle valve 5 in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com