Production scheduling method and system

A technology for production scheduling and scheduling problems, applied in control/regulation systems, general control systems, comprehensive factory control, etc., can solve problems such as many production disturbances, complex and difficult production scheduling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

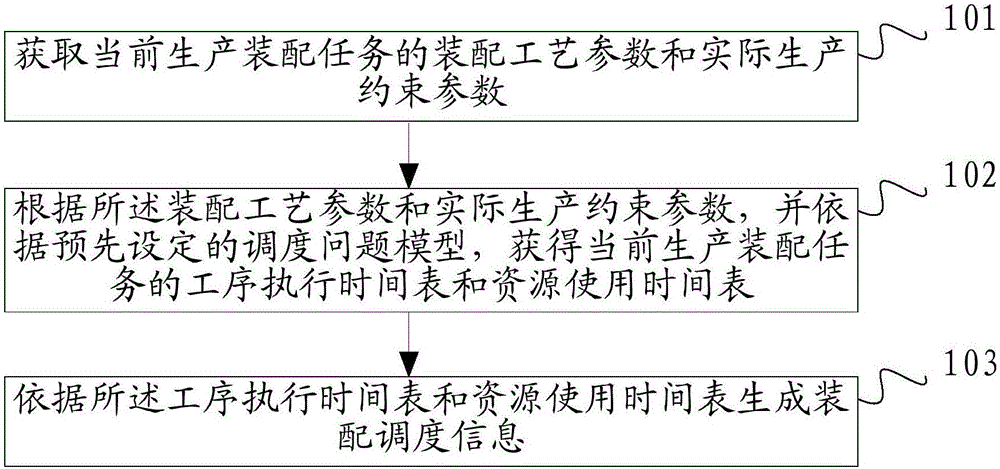

[0102] see figure 1 , the embodiment of the present invention provides a production scheduling method, including:

[0103] Step 101, obtaining assembly process parameters and actual production constraint parameters of the current production assembly task;

[0104] In the production scheduling method of the embodiment of the present invention, firstly, the assembly process parameters and actual production constraint parameters of the current production assembly task are obtained, wherein the assembly process parameters include: reusable resources required by the process, types of work required by the process, and The number of personnel, the requirements of the process for the station, the priority of the process, the rated working hours of the process and the non-reusable resources required by the process. The actual production constraint parameters include: the number and type of reusable resources, the number and type of personnel, the number and Functional category, quanti...

no. 2 example

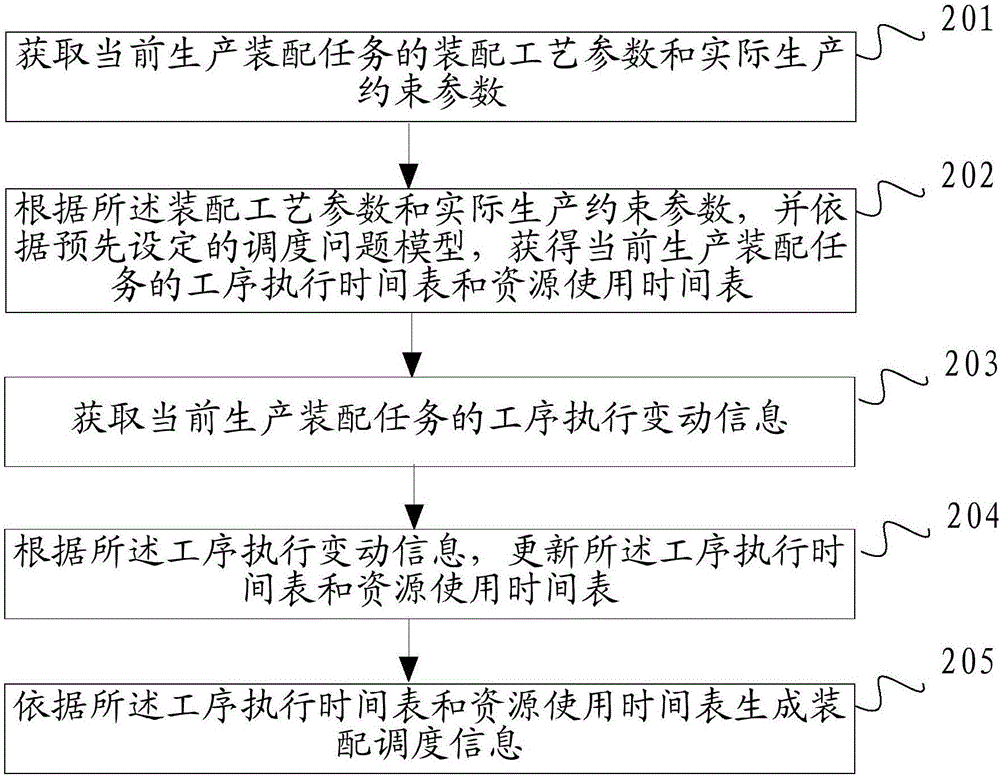

[0111] see figure 2 , further, for the first embodiment, according to the assembly process parameters and actual production constraint parameters, and according to the preset scheduling problem model, the process execution schedule and resource usage schedule of the current production assembly task are obtained After the step, the method also includes:

[0112] Step 203, acquiring process execution change information of the current production assembly task;

[0113] Wherein, the process execution change information includes: process execution time change, process suspension, process addition and process cancellation.

[0114] Step 204 , updating the process execution schedule and resource usage schedule according to the process execution change information.

[0115] The production process of complex product assembly is unstable, and there are many uncertain disturbance factors. For example, if the assembly process route in the process layer is changed, the original assembl...

no. 3 example

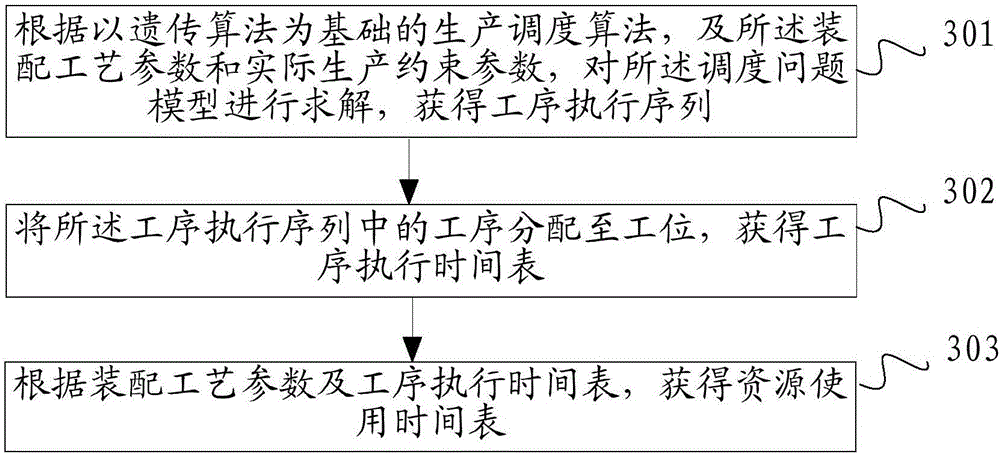

[0154] see image 3 , further, the step of obtaining the process execution schedule and resource usage schedule of the current production assembly task according to the assembly process parameters and actual production constraint parameters, and according to the preset scheduling problem model, includes:

[0155] Step 301: Solve the scheduling problem model according to the production scheduling algorithm based on the genetic algorithm, the assembly process parameters and the actual production constraint parameters, and obtain the process execution sequence;

[0156] Step 302, assigning the processes in the process execution sequence to workstations to obtain a process execution schedule;

[0157] Step 303, obtaining a resource usage schedule according to the assembly process parameters and the process execution schedule;

[0158] Wherein, the resource usage schedule includes: a reusable resource usage schedule and a non-reusable resource usage schedule.

[0159] The schedul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com