Automatic punching, engraving and milling machine

An automatic punching and all-in-one machine technology, which is applied in the direction of manufacturing tools and other manufacturing equipment/tools, etc., can solve the problems of debris affecting the working environment, inability to guarantee quality, waste of manpower and material resources, etc., to achieve reduced labor, strong versatility, and improved The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

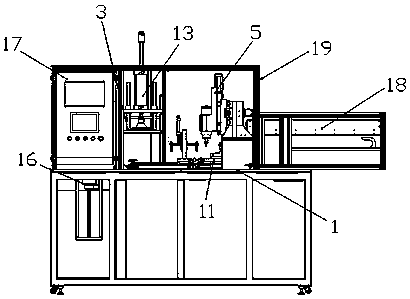

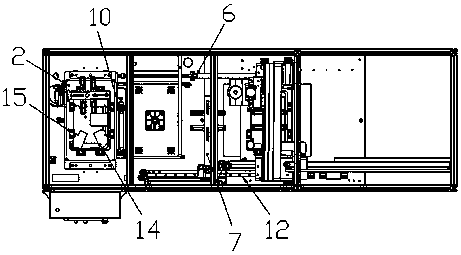

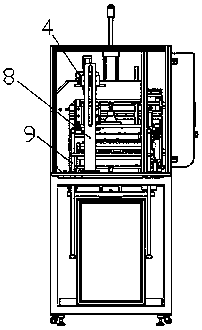

[0020] Attached below Figures 1 to 5 The present invention is further described. attached Figures 1 to 5 It schematically shows the automatic punching, cutting, engraving and milling machine of the present invention, including an automatic control device 17 and an operating platform 1, and the operating platform 1 is provided with a carrier 2, a punching mechanism 3, a material transfer mechanism 4, and an engraving and milling mechanism 5. The carrier 2 is connected with a forward and backward moving mechanism 6 through a connecting plate.

[0021] Preferably, the operating platform 1 is also provided with a feeding mechanism 7, the feeding mechanism 7 includes a rotary cylinder, a suction cup and an adjustment seat 8, the adjustment seat 8 can adjust the height up and down, and the rotary cylinder is installed on the adjustment seat 8 on, and can drive the suction cup to move.

[0022] Preferably, the carrier 2 is provided with a lifting mechanism 9 and an offset mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com