Material taking machine

A technology of reclaimer and cylinder, which is applied in metal processing and other directions, can solve the problems of poor practicability, dislocation, and narrow application range of reclaimers, and achieve the effect of increasing flexibility and practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

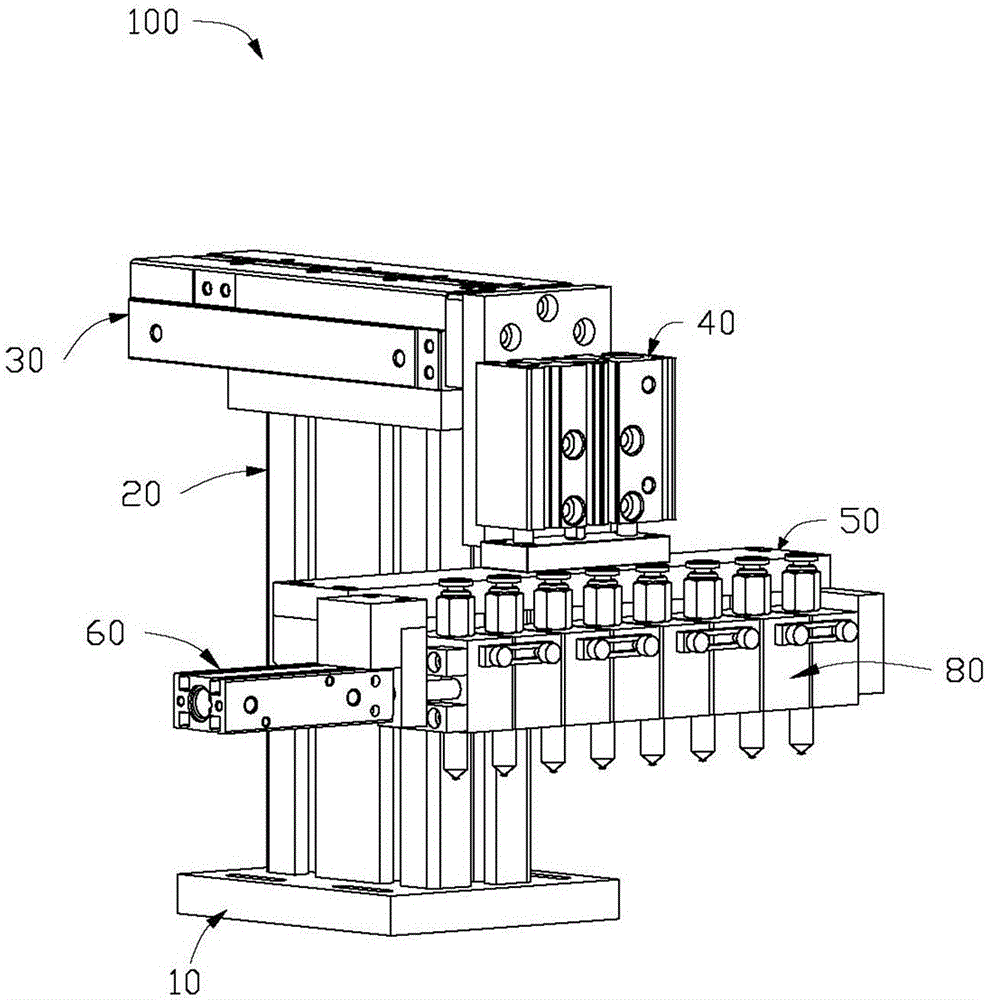

[0015] Such as figure 1 As shown, the reclaimer 100 in one embodiment of the present invention is used to suck products from the material tape and transfer the products to the carrier tape for packaging.

[0016] The reclaimer 100 includes a base 10, a rectangular support portion 20 extending vertically upward from the top of the base 10, a first cylinder 30 connected to the end of the support portion 20 away from the base 10, and The first cylinder 30 is fixedly connected to a second cylinder 40 , a connecting plate 50 connected to the second cylinder 40 , and a third cylinder 60 and nozzle module 80 fixed on the connecting plate 50 .

[0017] The base 10 and the supporting part 20 are rectangles with different sizes. The base 10 and the supporting part 20 can be integrally formed, or the supporting part 20 can be locked on the base 10 by screws. The supporting portion 20 is formed in the middle of the top of the base 10 .

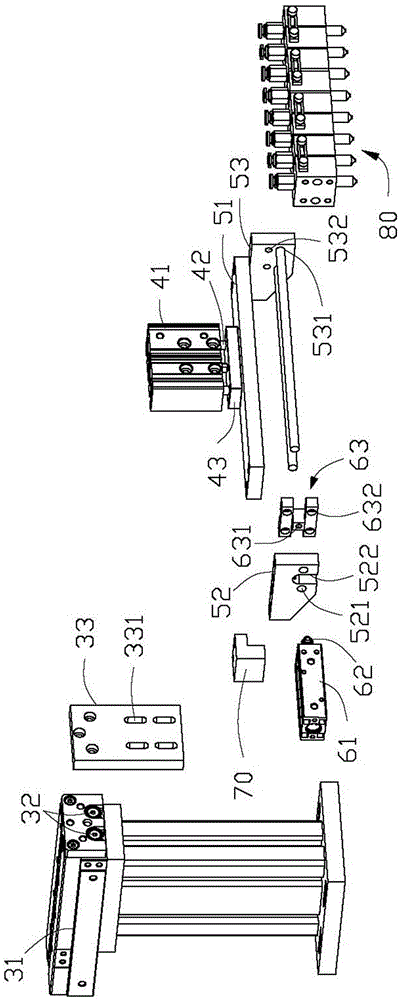

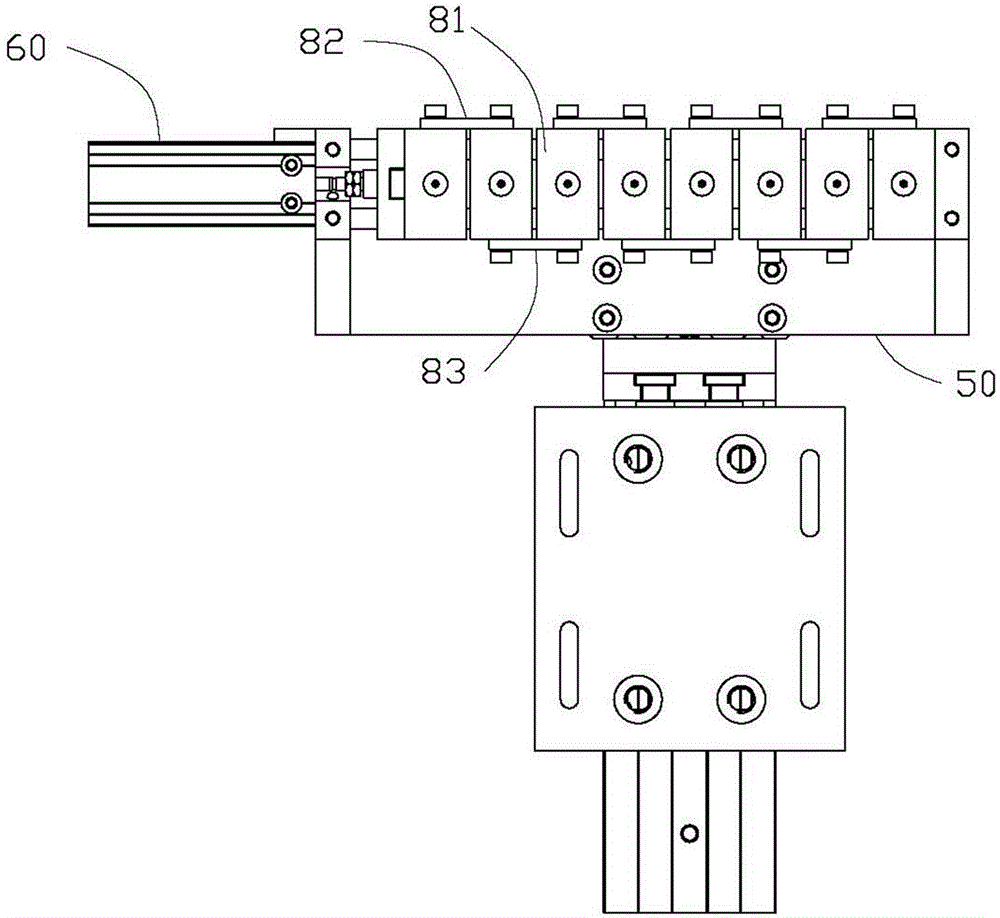

[0018] Please also refer to figure 2 , the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com