Rail type container portal crane lifting and rotating trolley

A technology for gantry cranes and containers, which is applied in the direction of cranes, trolley cranes, load blocks, etc., to achieve the effect of facilitating the operation of hanging boxes, shortening the wheel base, and reducing space layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

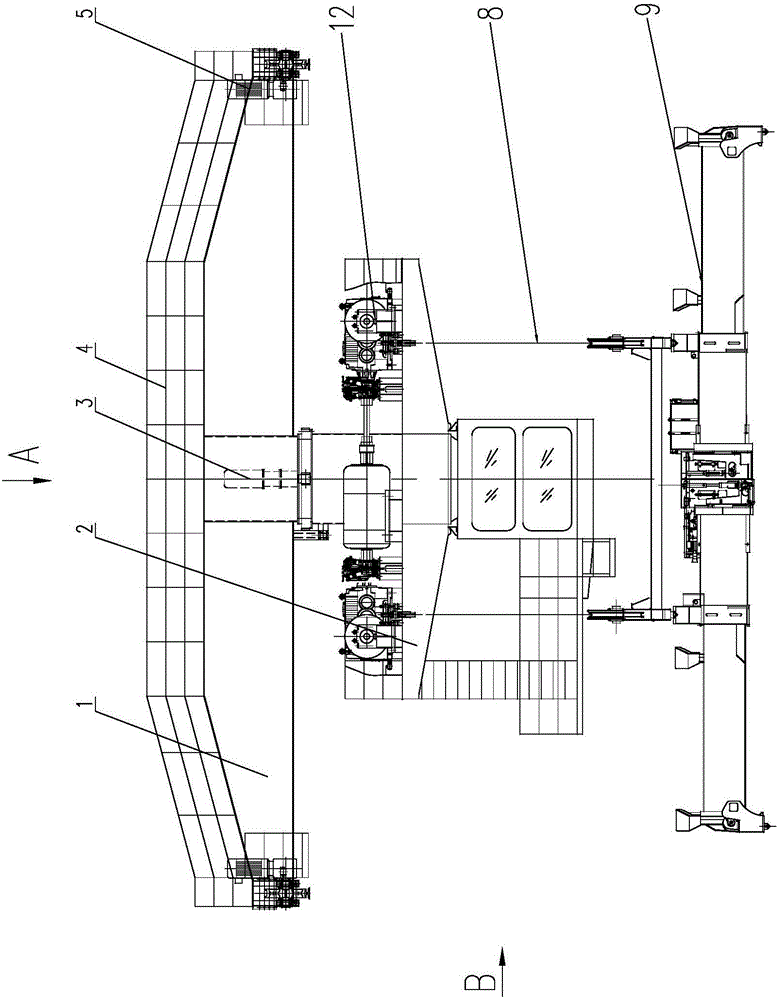

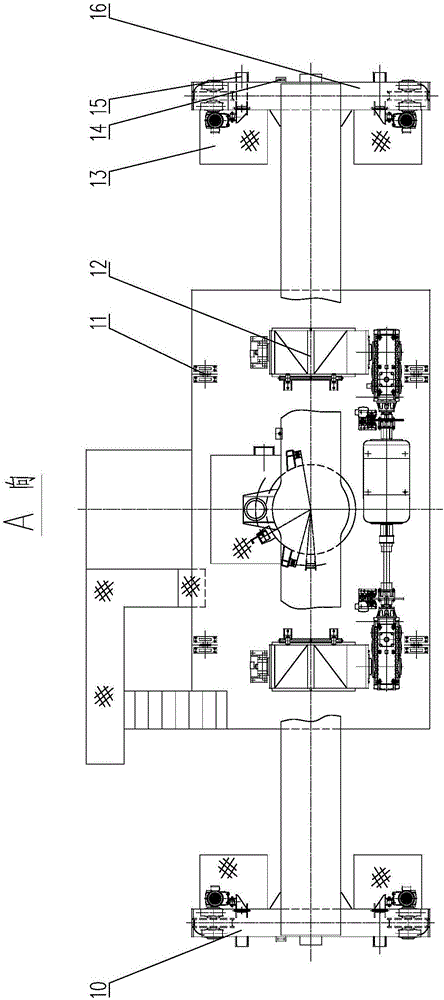

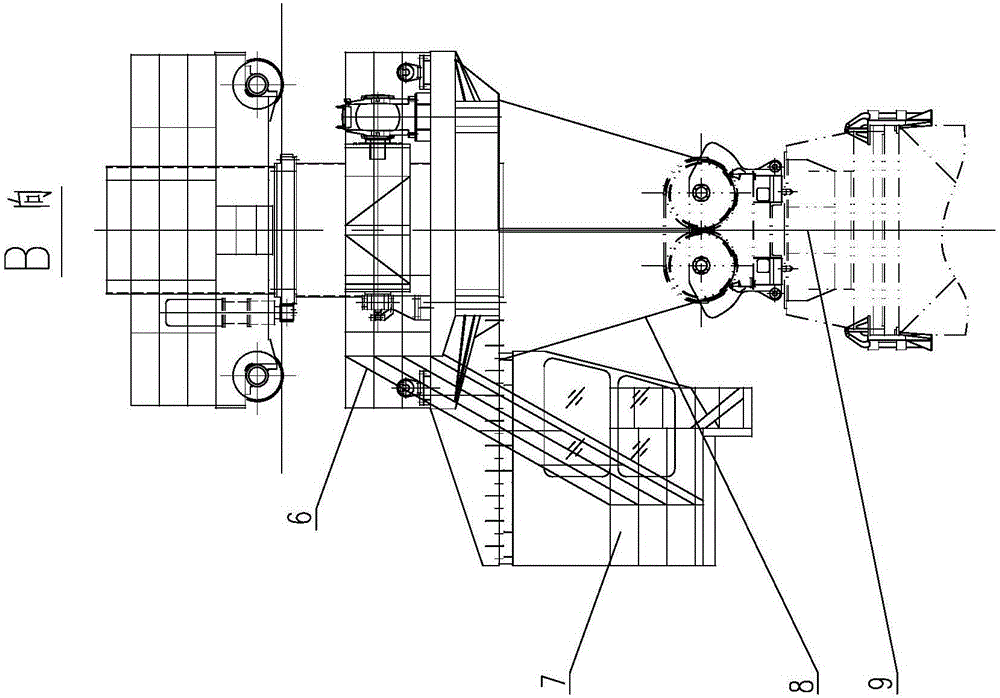

[0021] Such as Figure 1~3 As shown, the present invention mainly includes upper frame 1 of trolley, lower frame of trolley 2, lifting and rotating mechanism 3, trolley running mechanism 5, cab 7 with platform, first end beam 10, hoisting mechanism 12 and second end beam 16.

[0022] The middle part of the trolley upper frame 1 is connected to the trolley lower frame 2 through the lifting and rotating mechanism 3, and the left and right ends of the trolley upper frame 1 are respectively welded with the first end beam 10 and the second end beam 16, and the first end beam 10 and the second end beam 16 are provided with The trolley traveling mechanism 5, the front and rear sides of the first end beam 10 and the second end beam 16 are provided with an inspection platform 13 and a trolley top lifting seat 15, and the middle part of the first end beam 10 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com