Aluminum base silicon carbide composite material and preparing method thereof

A technology of aluminum-based silicon carbide and composite materials, which is applied in the field of packaging materials, can solve the problems of insufficient thermal conductivity, manufacturing process and welding performance, and restrict the application of materials, so as to change the difficulty of machining, low production cost, and hot isostatic pressing. The effect of low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be clearly and completely described below in conjunction with embodiments. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative work shall fall within the protection scope of the present invention.

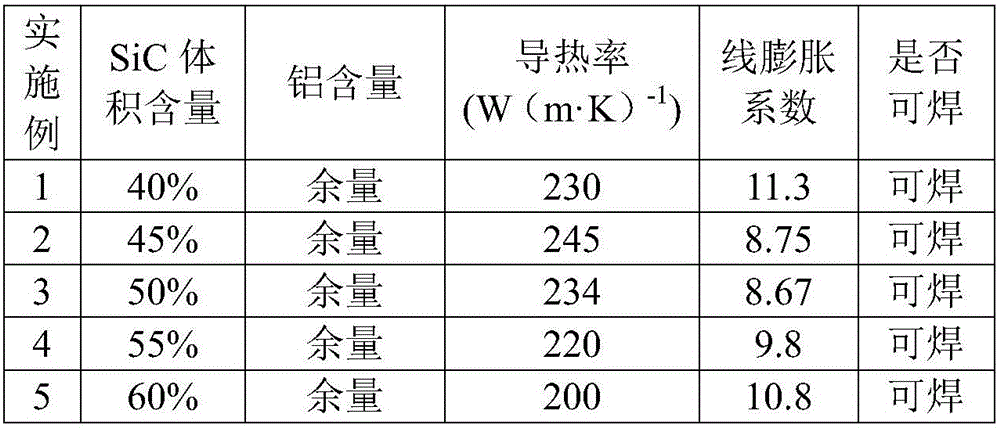

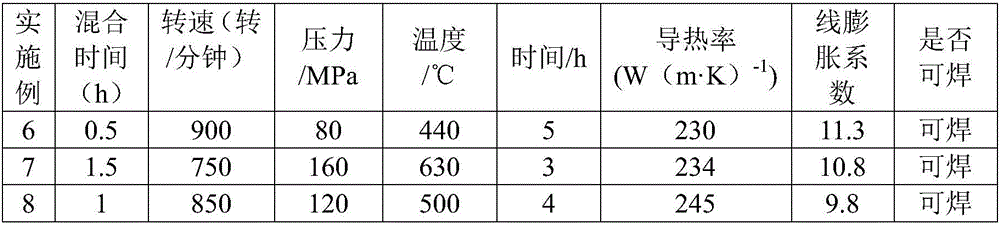

[0024] In terms of volume fraction, the SiC particles are 40% to 60%, and the balance is aluminum powder. The preparation steps are as follows:

[0025] The aluminum powder and the dried silicon carbide powder are sequentially put into the mixer to mix the powder. Take out a certain amount of mixed powder and put it into a pre-prepared aluminum alloy sheath. Vacuum degassing and hot isostatic pressing are performed on the aluminum alloy sheath containing the mixed powder, and finally the required silicon carbide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap