Experimental facility for integrity of fractured horizontal shaft

A horizontal wellbore and experimental device technology, applied in the direction of wellbore/well components, measurement, construction, etc., can solve the problems of not considering the influence of the integrity of the horizontal wellbore, and achieve the effect of improving the integrity of the wellbore and improving the service life of the wellbore

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

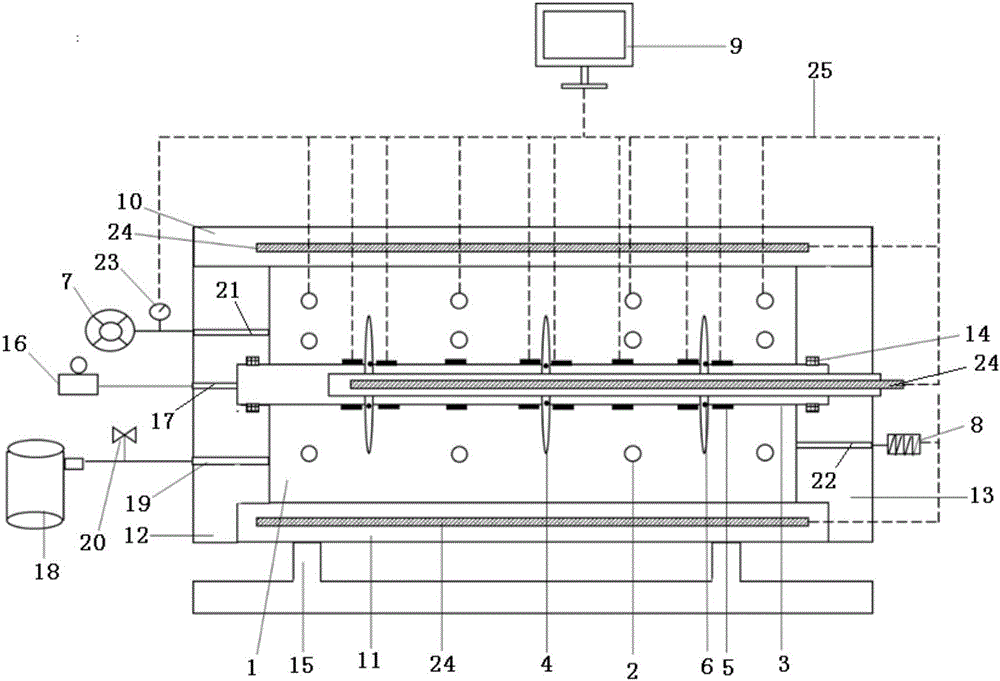

[0029] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

[0030] Such as figure 1 As shown, the present invention provides a fracturing horizontal wellbore integrity test device. The fracturing horizontal wellbore integrity test device includes a closed cavity 1 , and pressure sensors 2 are evenly distributed in the closed cavity 1 . The shape of the cavity 1 is preferably a rectangular cavity 1, the rectangular cavity 1 can simulate true triaxial stress, and the effect is better. A horizontal shaft 3 passes through the cavity 1 transversely, and the interior of the horizontal shaft 3 and the cavity 1 are isolated from each other by a tube wall. Perforation holes 4 and strain gauges 5 are provided on the wall of the horizontal wellbore 3, and the perforation holes 4 can simulate differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com