Simple auxiliary vehicle for tunnel quality detection

A technology for auxiliary vehicles and tunnels, which is applied in tunnels, mining equipment, earthwork drilling and mining, etc. It can solve the problems of complicated trolley installation, difficult trolley positioning, and slow down tunnel construction, so as to avoid inconvenient movement and high construction efficiency , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

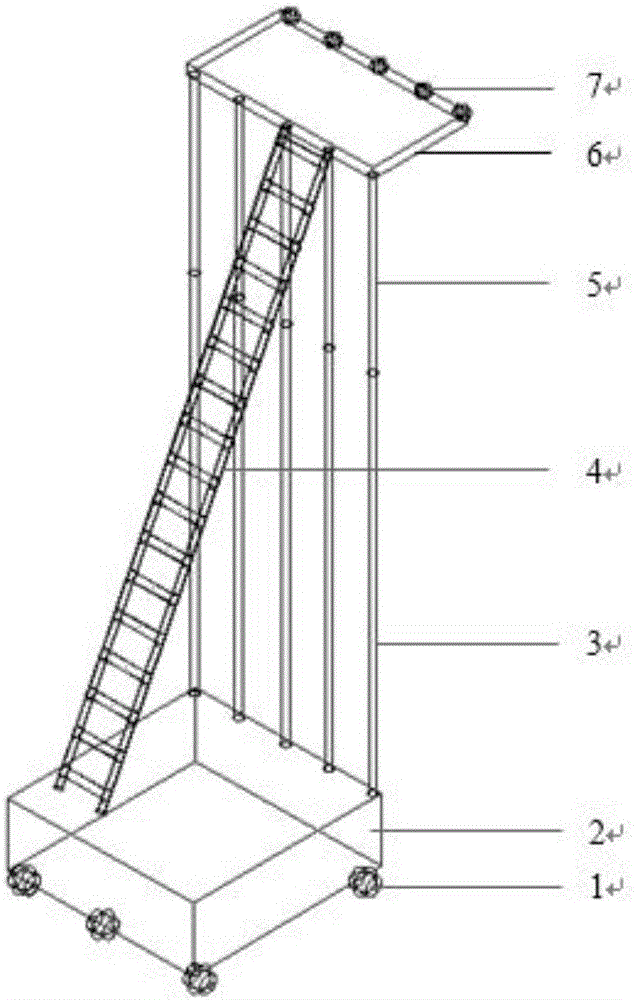

[0011] Such as figure 1 As shown, a simple auxiliary vehicle for tunnel quality detection, the present invention is characterized in that it includes the support seat of the present invention 2 of the present invention and the bottom roller located at the bottom of the support seat of the present invention 2 of the present invention of the present invention 1 of the present invention, and the support seat of the present invention 2. One side of the present invention is vertically arranged with lower steel pipes of the present invention. 3. The present invention. The bottom end of the lower steel pipes of the present invention 3. of the present invention passes through the support seat. 2. The present invention is directly connected with the bottom rollers of the present invention 1. Invention 3 The top of the present invention is connected with the upper steel pipe by nesting. In the present invention 5, the present invention uses screws to anchor, so that the height of the ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com